YY2002 Ultra High Flexible Ultra High Speed Special Cable for Drag Chains TRVV With Shield

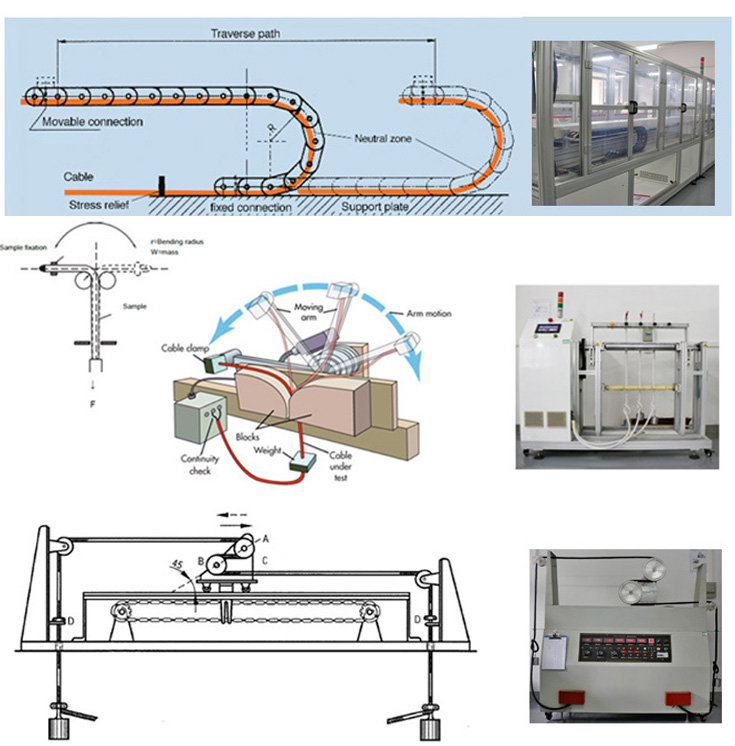

Explanation of cable load capacity:

In long-travel drag chain applications, due to the weight of the cable itself and the stress generated during high-speed movement of the drag chain, as well as the limited freedom of cable installation in long-travel drag chains, the cable itself needs to withstand significant tensile forces. The longer the travel distance of the drag chain, the greater the forces applied, thus requiring higher load capacity for the cable

High Load: Suitable for applications with drag chain travel distances up to 100 meters, with high load capacity. Examples include the 20 million cycle YY2001, YY2002, YY2006 series with PVC sheathing.

Very High Load: Suitable for applications with drag chain travel distances up to 200 meters, with extremely high load capacity. Examples include the 20 million cycle YP2001, YP2002, YP2006 series with PUR sheathing.

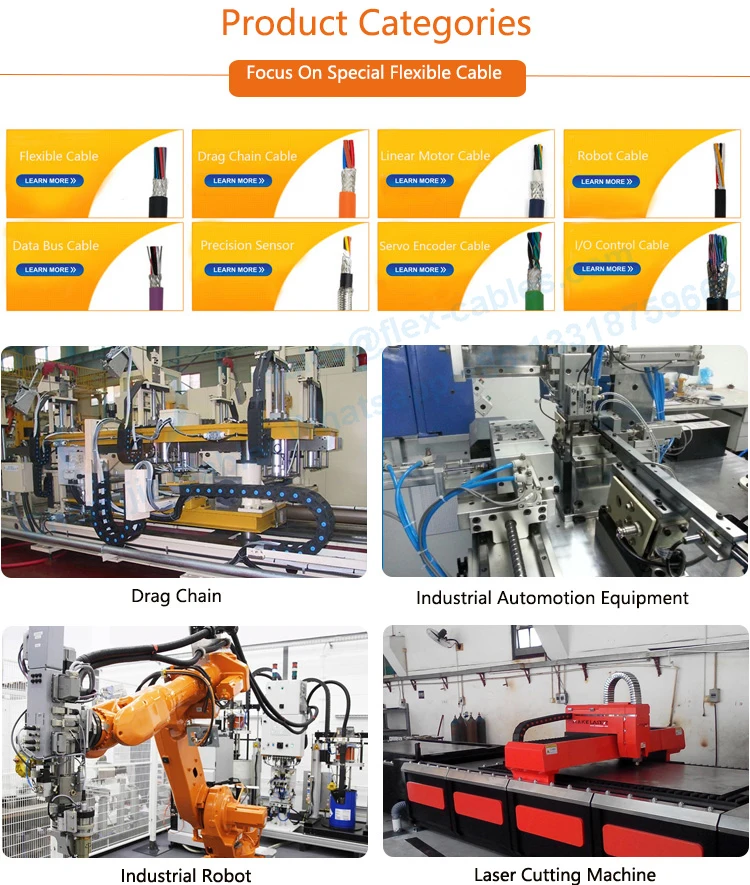

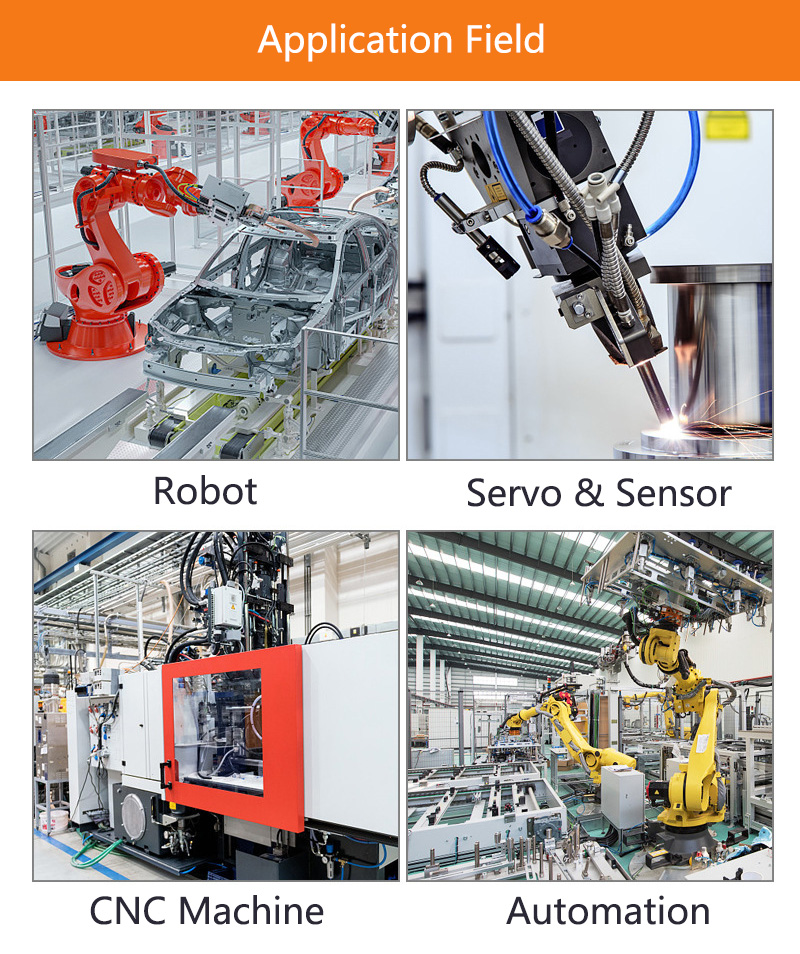

Application

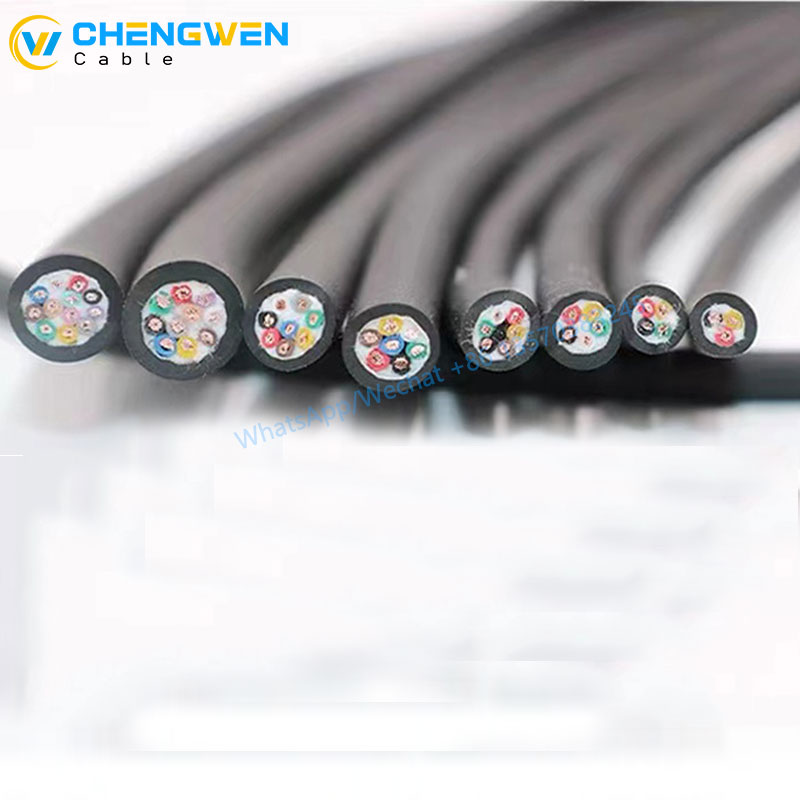

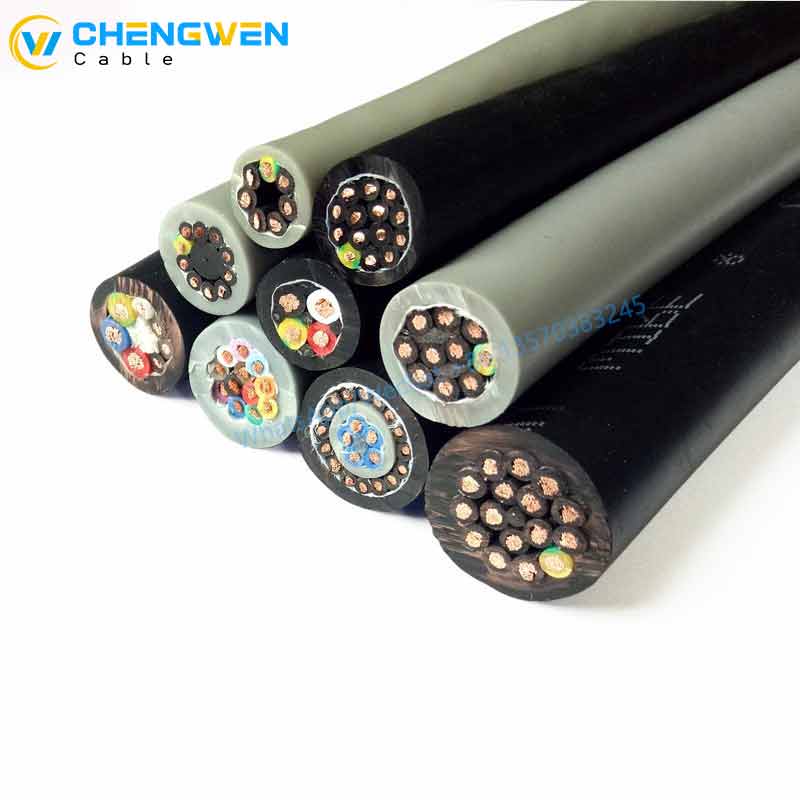

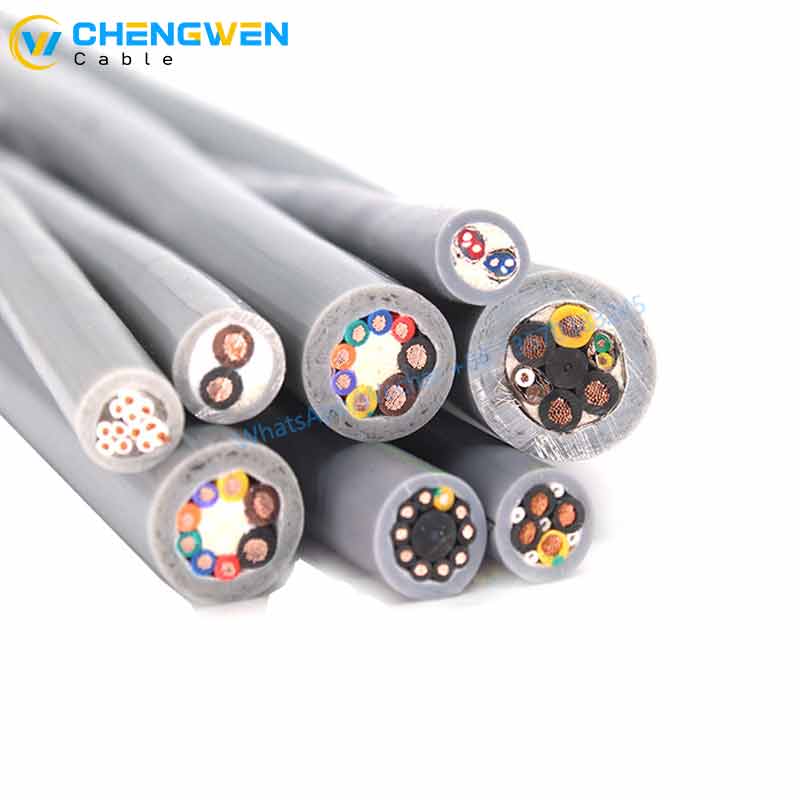

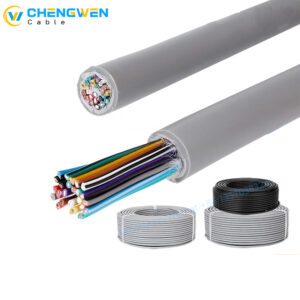

● The cable adopts a crimped double sheath structure, with conductors twisted from ultra-fine copper wires of 0.08mm, exceptionally resistant to bending.

● It has a relatively stiff feel compared to ribbon-type structured cables, and the outer diameter is also larger than that of ribbon-type structured cables.

● Equipped with a shield layer of tinned copper wire braid to maximize the elimination of signal interference.

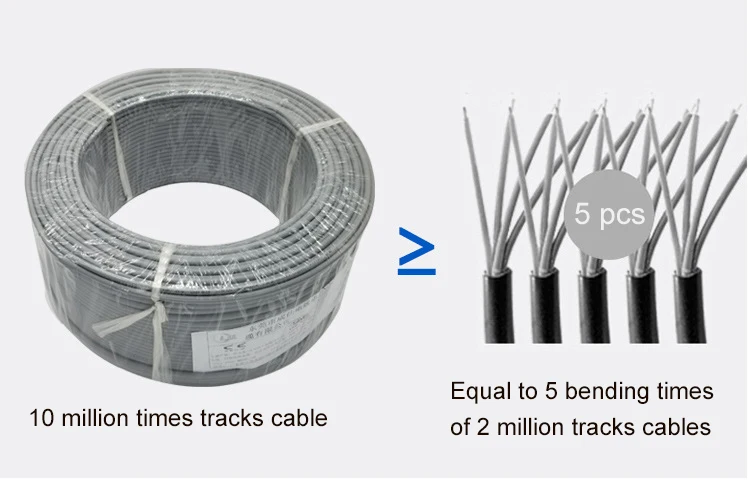

● Internally designed to minimize wear on the core wires caused by the braided layer, thus extending the service life. Moderately oil-resistant, with excellent resistance to wear, high and low temperatures, and strong load capacity. Under standard installation and usage,

it can achieve a service life of over 20 million cycles, suitable for use in high-speed motion drag chains.

Technical data

● Special PVC sheath with special structure, featuring ultra-high flexibility.

● Complies with TUV 2 PfG 2577 Class II requirements.

● Temperature range: For mobile installation: -5°C to +70°C. For fixed installation: -15°C to +80°C.

● Nominal voltage Uo/U 300/300V.

● Test voltage: 1500V.

● Insulation resistance: Minimum 20 MOhmxkm.

● Minimum bending radius:For mobile installation: 6 times the cable diameter. For fixed installation: 4 times the cable diameter.

● Complies with EU RoHS and Reach regulations.

●Oil resistance: Medium oil resistance

● Compliant with EU RoHS and Reach regulations.

● Flame retardant, compliant with IEC 60332-1、CEI 20-35、FT1、VW-1

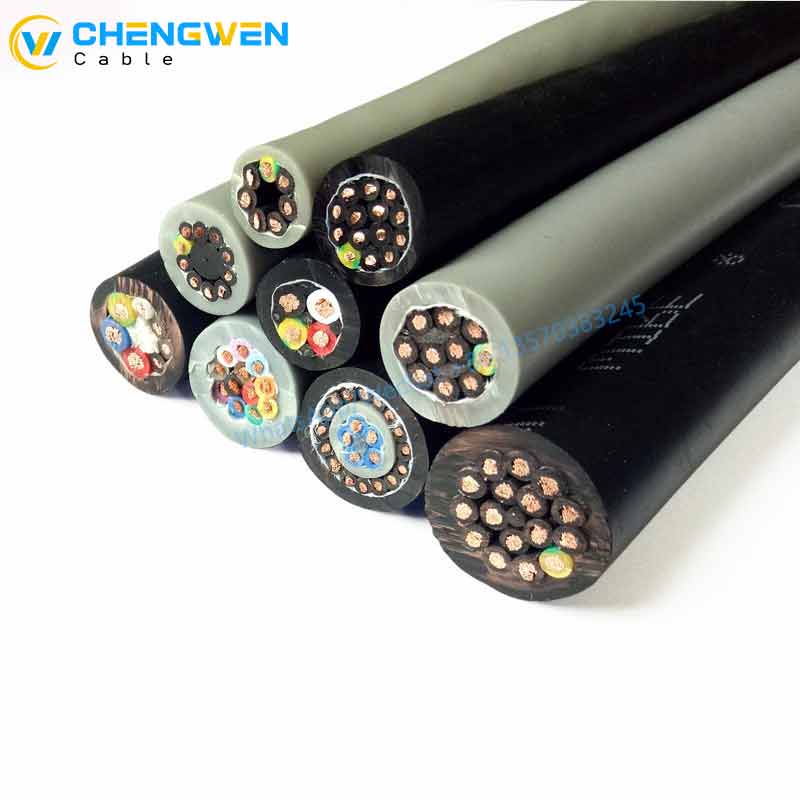

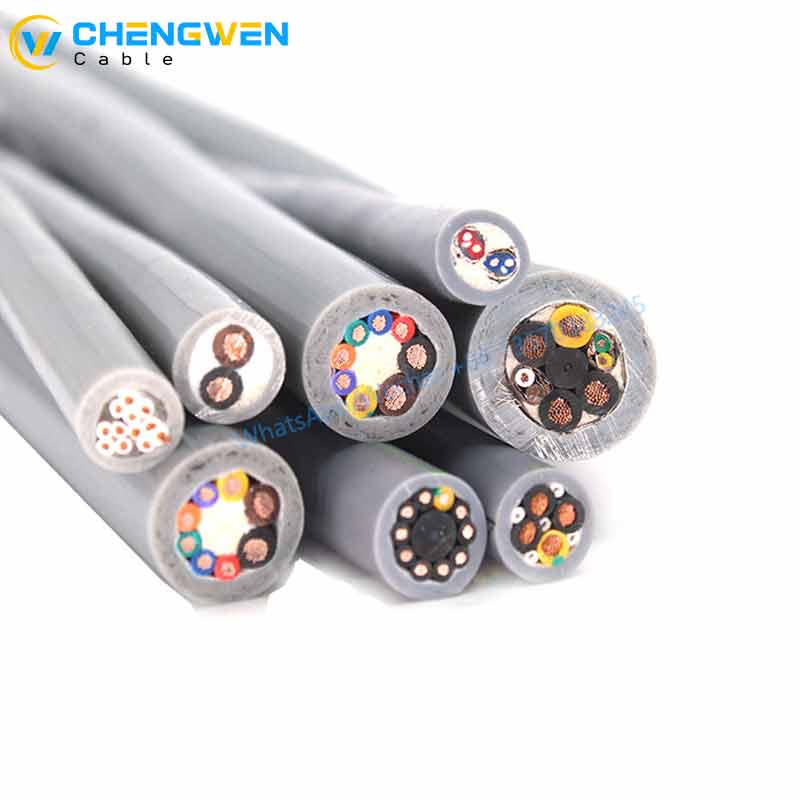

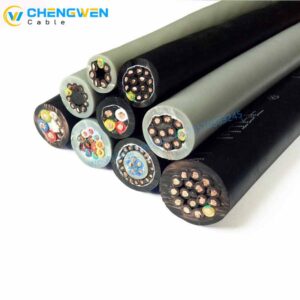

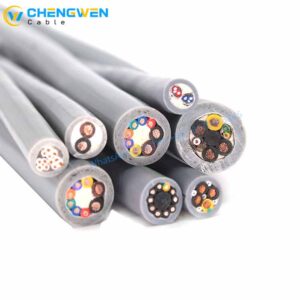

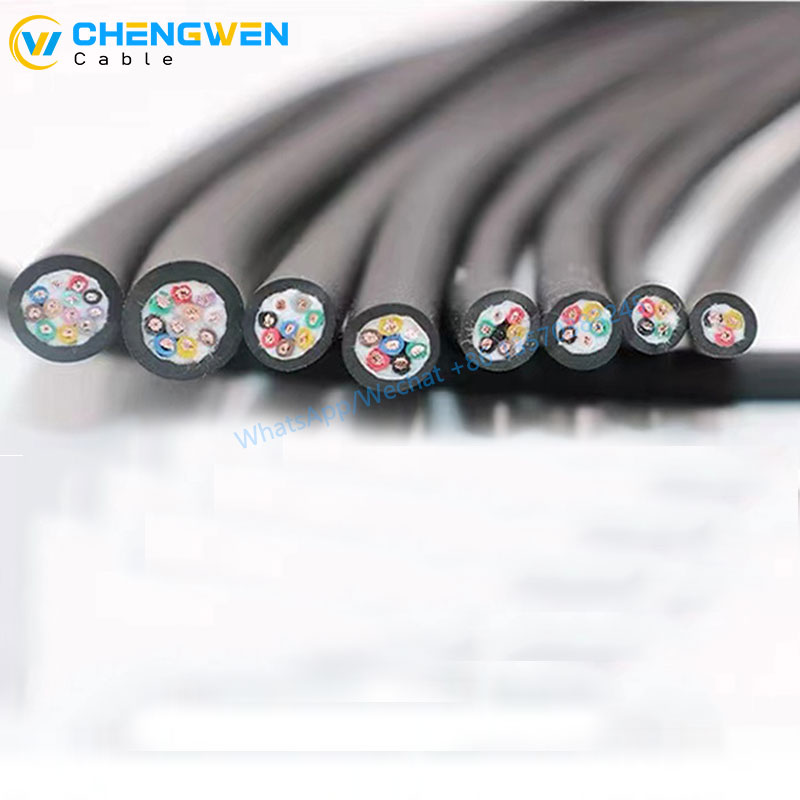

Cable Structure

● Tin-plated copper (below 0.5mm²) or bare copper (0.5mm² and above) conductors.

● Ultra-fine copper wires, compliant with DIN VDE 0295 Class 6 and IEC 60228 Class 6.

● Special PVC insulation.

● Color-coded cores (below 0.5mm²).

● Black cores with continuous white numeric marking (0.5mm² and above), with a yellow-green grounding wire on the outer layer (3 cores and above).

● Optimal pitch grouped twisted cores (12 cores and above), layered twisted below 12 cores.

● Improved tinned copper wire braided shield.

● Minimum coverage rate of 90%.

● Low viscosity, oil-resistant PVC-based composite material

● Grey or color can be customized according to customer requirements.

G= represents the yellow-green grounding wire. For more specifications or special custom products, please contact our product consultant.

It is recommended to split the high-speed drag chain cable with 20 cores or more into two separate cables.

For the cables ordered by the coil above, the minimum order quantity for cables with PUR sheath type is 400 meters.