Strong customization and meet the different needs of customers

Industrial Cable

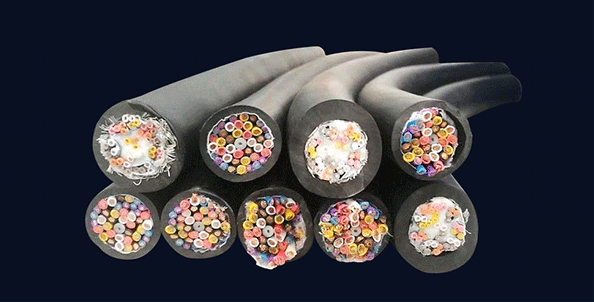

We are the top player in the market for special industrial cables catering to demanding and harsh application requirements. Our team of skilled engineers specializing in electrical cables has over 15 years of experience in crafting high-performance cable solutions.

Custom Cable Solutions

Chengwen specializes in designing customized cable solutions that are tailored to meet your specific requirements and application needs. Our deep understanding of the many challenges faced by your industry ensures that we can provide you with reliable and effective solutions that meet your unique demands.

Cable Assemblies

With more than 10 years of experience in building high quality cable assemblies for a diverse range of customers and applications. Our practical expertise in the industry, coupled with our cutting-edge design center, enables us to meet your demand.

Product Category

Our Main Product Line

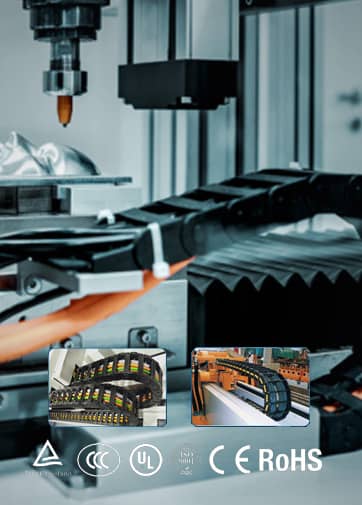

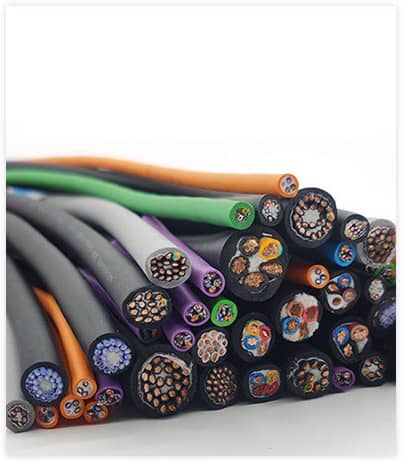

Chengwen specializes in designing and manufacturing a wide range of industrial special cables customized for different environments and fields. Our main products, including robot cables, industrial cables, sensor cables, drag chain cables, data bus cables,ethernet cable,flexible cables, control cables, elevator traveling cables, crane cables, flat crane traveling cables, and drum-reeling cables, are made using materials such as PUR/TPU, TPE, ETFE, and Silicone. They are tailored to specific requirements, like being cold-resistant, corrosion-resistant, UV-resistant in cold regions, waterproof and corrosion-resistant in humid areas, and capable of withstanding seawater and acidic conditions. In mechanical manufacturing, our cables exhibit properties like oil resistance, compression resistance, fire resistance, or flame retardance. For high-density control applications, they provide high interference resistance, fatigue resistance, wear resistance, and flexibility.

Linear Motor Cable

Bus Cable

Recommendation

Hot Sales

Challanges

Do You Encounter The Following Problems When Using The Flexible Cable ?

Core Break

The core wire is stretched by a mechanical load or a stretching stretch of regular bending.

Core Break

The core wire is stretched by a mechanical load or a stretching stretch of regular bending.

Spiral Deformation

Unreasonable upper structures and high -intensity bending pressures that cables bearing are caused by spiral deformation.

Spiral Deformation

Unreasonable upper structures and high -intensity bending pressures that cables bearing are caused by spiral deformation.

Shielding Layer Break

Incorrect shielding angle and the shielding layer caused by mechanical load damage.

Shielding Layer Break

Incorrect shielding angle and the shielding layer caused by mechanical load damage.

Insulation Rupture

Regular bending force causes the wear of the conductor core wire or shielding layer, thereby piercing through the insulation layer.

Shielding Layer Break

Incorrect shielding angle and the shielding layer caused by mechanical load damage.

Why Chengwen Cable

You need a professional industrial cable manufacturer to help you avoid the above problems.

Industrial motion cables have more stringent requirements for product precision, technology, and materials. Therefore, we have customized all of their production equipment and adopted special materials and rigorous processes to meet the high-standard demands.

1. Conductor Twisting

All conductors adopt ultra-fine conductors with low resistance, high conductivity, high elongation, strong tensile strength, and fatigue resistance. Commonly used conductors are 0.05 to 0.08 millimeters in diameter, and are twisted in opposite directions with small pitches, which greatly improves the mechanical performance of the conductors.

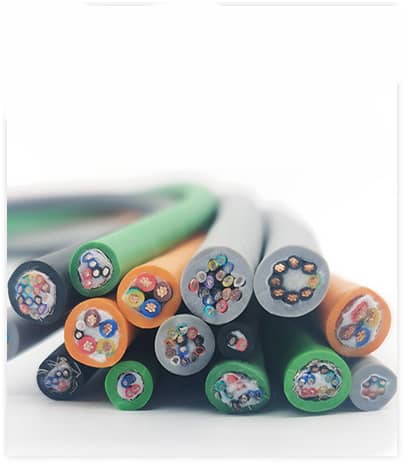

2. Insulation Extrusion

Special materials for insulation are customized according to different customer requirements, and the outer diameter precision is controlled within one-thousandth of a millimeter. The production line conducts online detection of cold and hot diameters, spark detection, concave-convex detection, and defect printing to ensure high-quality, high-precision, and high concentricity of the product.

3. Strand Cable

All cable stranding equipment, including pre-twisted single-twist machines and pre-twisted cage twist machines, adopt a pre-twisting design and broken wire induction. The stable and uniform twisting pitch ensures that the cable is more rounded and consistent during stranding and cabling.

4. Shielding Braiding

After cabling, shielding processes are carried out according to different customer requirements. The two main shielding methods are braiding and wrapping. Specific pitches are used to achieve a shielding coverage of ≥85%, thereby enhancing the anti-interference capability and durability of the shield.

5. Jacket Extrusion

Special mixed materials such as PVC, TPU, and ETFE with flame retardant, waterproof, oil-resistant, wear-resistant, cold-resistant, and UV-resistant properties are used for jacket extrusion. All jackets undergo online diameter detection, high-voltage spark detection, and closed-loop tension control to ensure the product is more visually pleasing and durable.

6. Quality Control

In order to ensure the high quality and stability of the product, strict technical inspections are carried out before the cable leaves the factory. This includes physical fatigue testing, environmental performance testing, and electrical performance testing. The product is only delivered to the customer after passing all tests satisfactorily.

Decades of Experience You Can Count on

Established in 2008, Chengwen is a leading cable manufacturer offering end-to-end solutions, from R&D to sales and service. Utilizing cutting-edge equipment, our expert team delivers custom industrial cable solutions to various industries. We prioritize customer satisfaction and quality, becoming a trusted partner for exceptional, bespoke cable needs.

13+

Years Experiences

426+

Satisfied Customers

18000㎡

Occupied

- Free sample, Massive inventory

- 6 modern production workshop

- 500 sets production and testing equipment

- UL, CE, CCC, TUV, CNAS, IPA, TF169949 Certification

- Experienced R&D Team With Advanced TUV Test Lab

Reviews

Over 1800 Customers Trust Us

How Chengwen Cable Suppot Your Bussiness

Provide Free Sample

We have a lot of inventory ready to ship,if you need,we would like to sent the free sample for you to test.

100% Online Support

Wherever you are, whenever the time, Chengwen team online support is 7/24 ready for you.

Worry-free After-sales Service

From cable selection to on-site installation, we can provide professional solutions to ensure a worry-free after-sales experience for our customers.