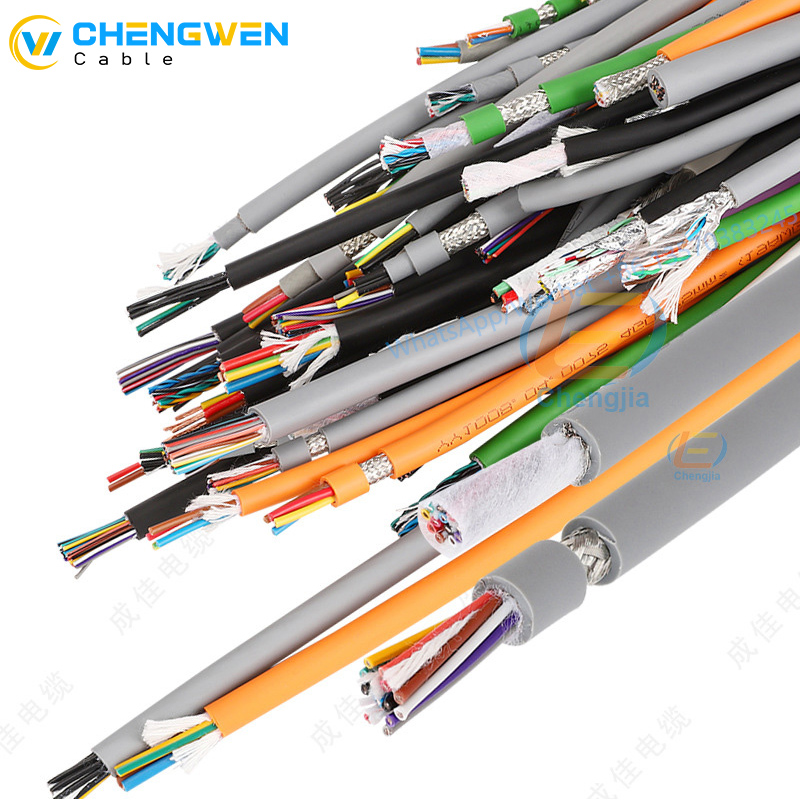

Ultra -high -speed motion tight -type TRVVP ultra high flexible drag chain cables are suitable for mechanical equipment and machine

tools, high loads, and high -flexible high -speed drag chain bend applications. This ultra -high flexible cable uses special modified

insulation materials and external quilt materials, as well as special structures, has high abrasion resistance and medium resistance,

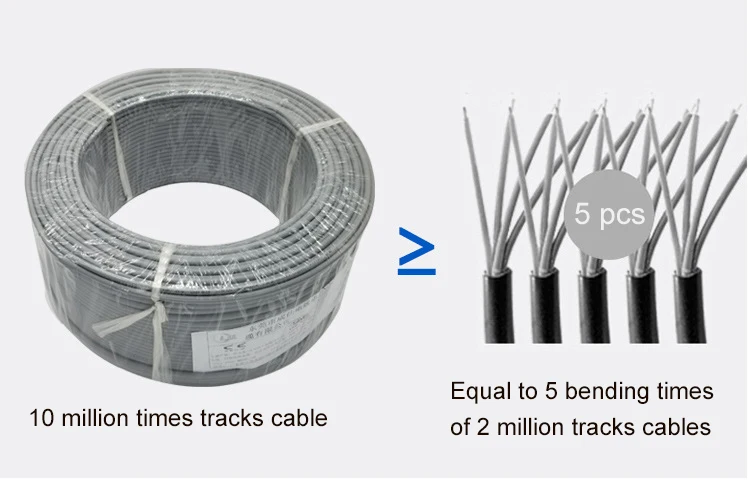

can withstand long -term acceleration, deceleration, stretching and compression stress, and 10 million times, and 20 million times

The above periodic bending and maintaining high stability.

YY1001 TRVVP Ultra high flexible drag chain cables Technical Parameter

|

Standard

|

Comply with EU RoHS and Reach regulations

|

|||

|

Conductor

|

adopts high-quality tinned copper stranded copper wire

|

|||

|

Insulation material

|

Special PVC sheath with high flexibility

|

|||

|

Temperature range:

|

Mobile installation -5 °C to +70°c

Fixed installation -15 °C to +80°c

|

|||

|

Insulation resistance:

|

Minimum 20 MOhm x km

|

|||

|

Outer sheath

|

Modified PVC mate

|

|||

|

Minimum bending radius:

|

Mobile installation 7.5×cable diameter

Fixed installation 6×cable diameter

|

|||

|

Nominal voltage

|

Uo/U 300/300 V

|

|||

|

Test voltage

|

1500 V

|

|||

|

Application:

|

It is especially suitable for continuous ultra-high flexibility and high-speed towline bending applications of mechanical equipment and machine tools. The ultra-high flexible cable uses specially modified insulating materials and outer covering

materials, which have high abrasion resistance and medium resistance, and can withstand long-term acceleration, deceleration, tensile and compressive stress, and more than ten million cycles of periodic bending , And always maintain high stability. |

|||

YY1001 TRVVP Ultra high flexible drag chain cables Structure

YY1001 TRVVP Ultra high flexible drag chain cables Structure

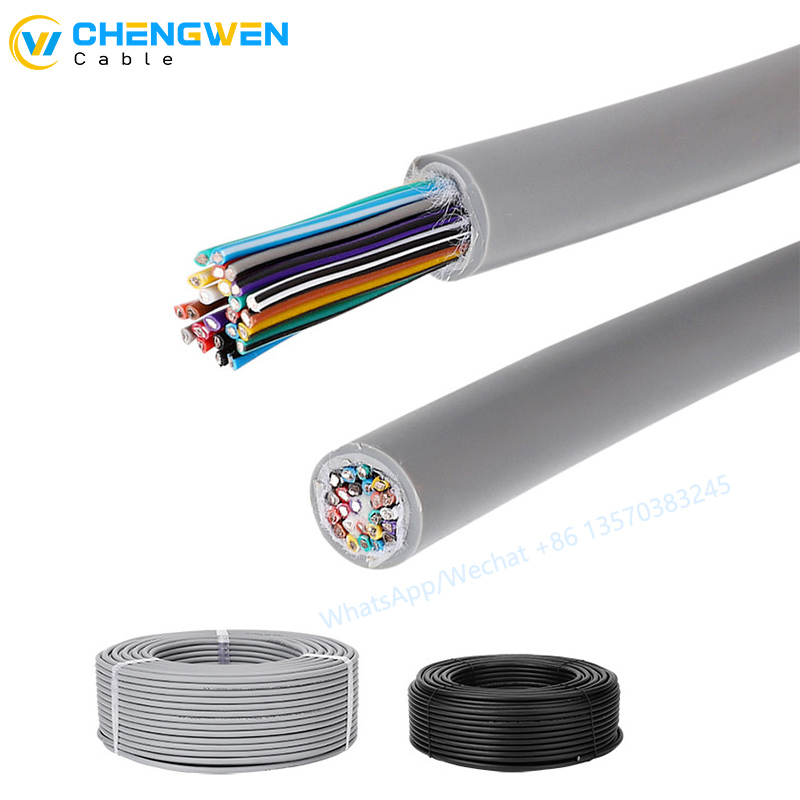

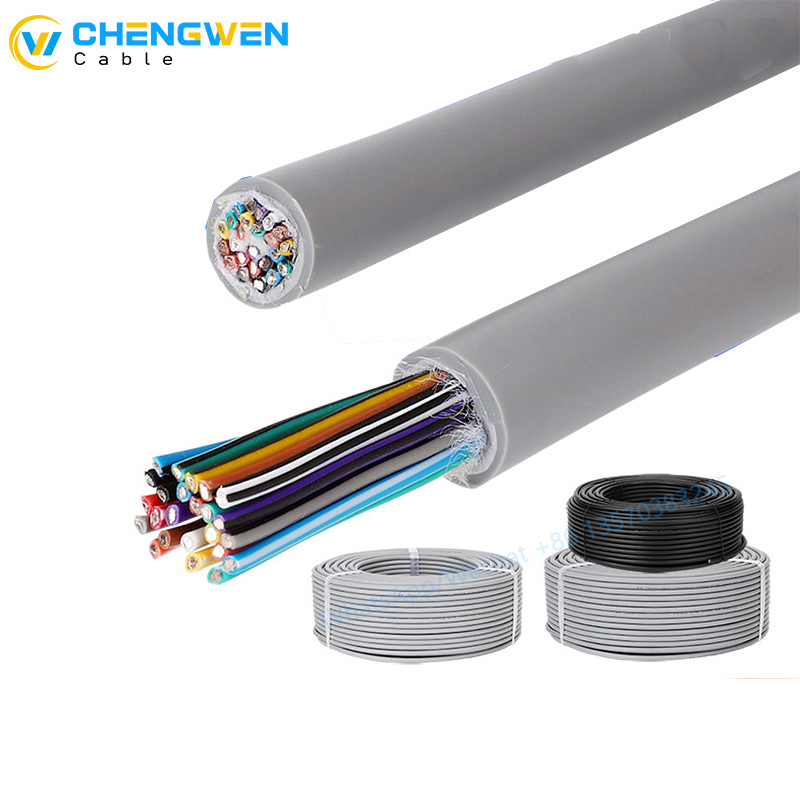

1. Bare copper conductor, ultra-fine copper wire Comply with DIN VDE0295 category 6 and IEC 60228 category 6

2. Special PVC insulation

3. Black core wire, with continuous white digital code, yellow-green ground wire on the outer layer (3 cores and above)

4. The wire core is stranded in layers with the best pitch

5. Special PVC outer sheath

6. Gray (RAL 7001) matte