Technical Parameter Of Robot Towline PVC Drag Chain Cable

|

Standard

|

Comply with EU RoHS and Reach regulations

|

|||

|

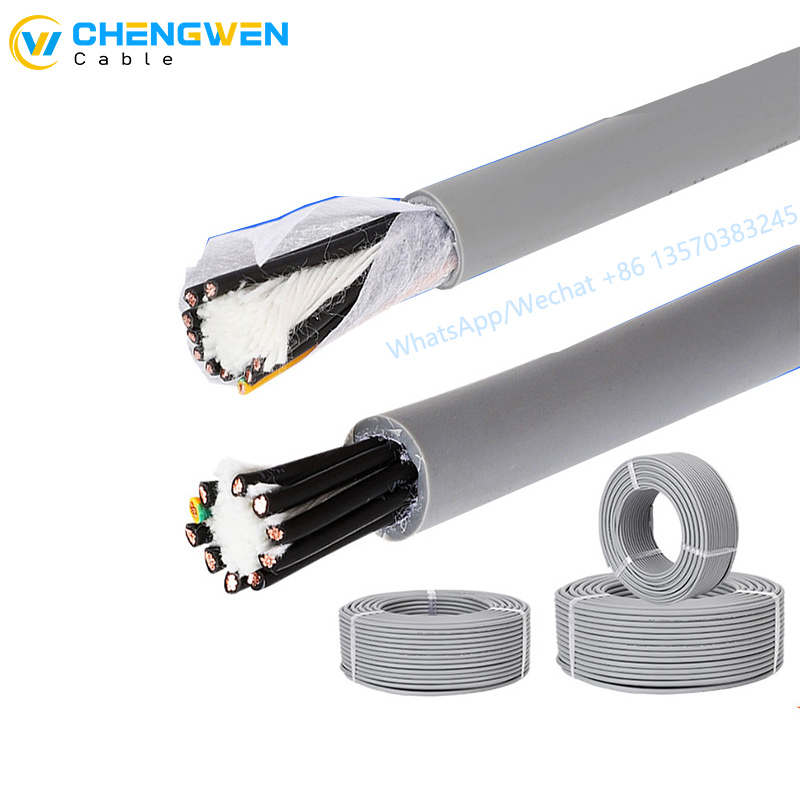

Conductor

|

adopts high-quality tinned copper stranded copper wire

|

|||

|

Insulation material

|

Special PVC sheath with high flexibility

|

|||

|

Temperature range:

|

Mobile installation -5°C to +70°c

Fixed installation -15°C to +80°c

|

|||

|

Insulation resistance:

|

Minimum 20 MOhm x km

|

|||

|

Color

|

Black (other colors can be customized)

|

|||

|

Minimum bending radius:

|

Mobile installation 7.5×cable diameter

Fixed installation 6x cable diameter

|

|||

|

Nominal voltage

|

Uo/U 300/300 V

|

|||

|

Test voltage

|

1500 V

|

|||

|

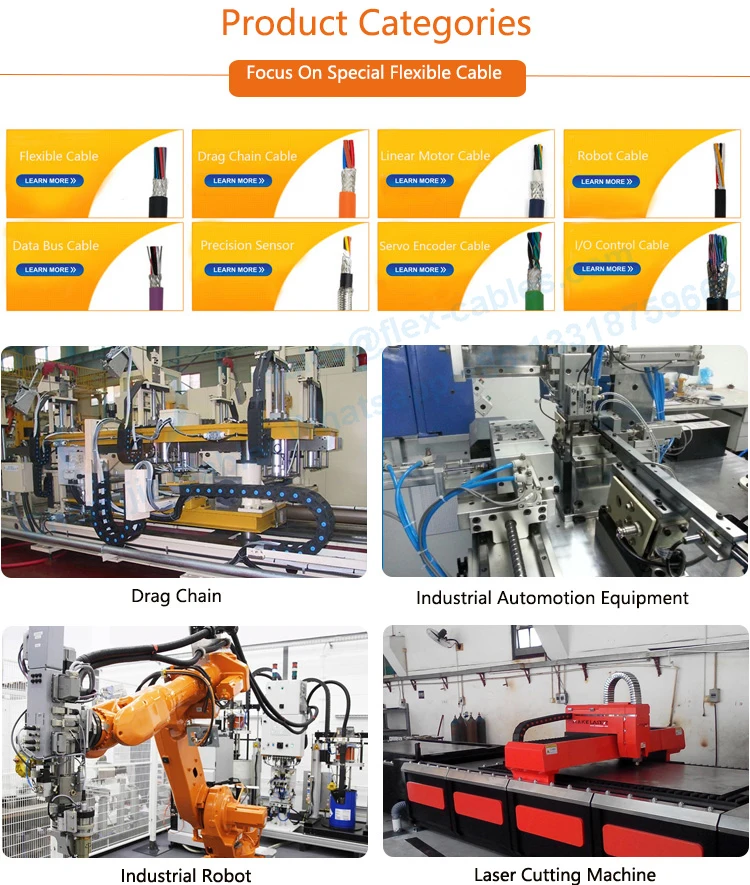

Application:

|

Suitable for various non-standard automated production equipment such as CNC machine tools, industrial robots, servo drives,

woodworking machinery, mask machines, manipulators, dispensing machines, laser equipment, stamping lines, logistics automation, ceramic production equipment, etc., which can withstand long-term acceleration, Deceleration, tensile and compressive stress, and high-speed periodic bending, and always maintain high stability. |

|||

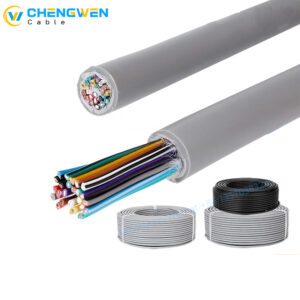

Robot Towline PVC Drag Chain Cable Structure

Robot Towline PVC Drag Chain Cable Structure

|

No.

|

Product Code

|

Cores Number and cross-sectional area

(NO.Xm㎡)

|

Approximate outer diameter (mm)

|

Outer sheath color

|

20℃ Conductor DC resistance

Ω/km

|

|

1

|

YY1001.02.0020

|

2×0.2

|

4.4

|

Gray

|

95

|

|

2

|

YY1001.03.0020

|

3×0.2

|

4.6

|

Gray

|

95

|

|

3

|

YY1001.04.0020

|

4×0.2

|

5.0

|

Gray

|

95

|

|

4

|

YY1001.05.0020

|

5×0.2

|

5.2

|

Gray

|

95

|

|

5

|

YY1001.06.0020

|

6×0.2

|

5.6

|

Gray

|

95

|

|

6

|

YY1001.08.0020

|

8×0.2

|

6.4

|

Gray

|

95

|

|

7

|

YY1001.10.0020

|

10×0.2

|

7.2

|

Gray

|

95

|

|

8

|

YY1001.12.0020

|

12×0.2

|

7.0

|

Gray

|

95

|

|

9

|

YY1001.16.0020

|

16×0.2

|

7.5

|

Gray

|

95

|

|

10

|

YY1001.20.0020

|

20×0.2

|

8.2

|

Gray

|

95

|

|

11

|

YY1001.02.0030

|

2×0.3

|

4.6

|

Gray

|

71.2

|

|

12

|

YY1001.03.0030

|

3×0.3

|

4.8

|

Gray

|

71.2

|

|

13

|

YY1001.04.0030

|

4×0.3

|

5.2

|

Gray

|

71.2

|

|

14

|

YY1001.05.0030

|

5×0.3

|

5.6

|

Gray

|

71.2

|

|

15

|

YY1001.06.0030

|

6×0.3

|

6.0

|

Gray

|

71.2

|

|

16

|

YY1001.08.0030

|

8×0.3

|

6.8

|

Gray

|

71.2

|

|

17

|

YY1001.10.0030

|

10×0.3

|

7.6

|

Gray

|

71.2

|

|

18

|

YY1001.12.0030

|

12×0.3

|

7.4

|

Gray

|

71.2

|

|

19

|

YY1001.16.0030

|

16×0.3

|

8.0

|

Gray

|

71.2

|

|

20

|

YY1001.20.0030

|

20×0.3

|

8.6

|

Gray

|

71.2

|

|

MOQ 1 meter, If you need to order PUR outer sheath, MOQ 400 meters

|

|||||