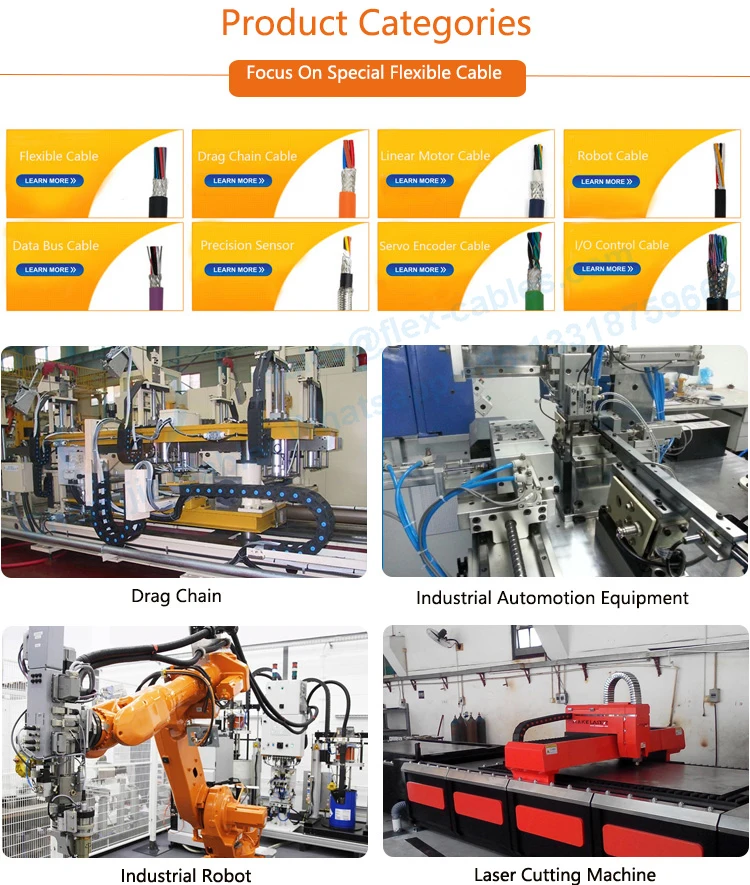

It is suitable for installation under continuous reciprocating motion, especially the frequent bending occasions under the

industrial environment, the drag chain of modern machinery standard components and the logistics system, operating system,

mechanical automation system and other CNC machine tools, electronic equipment, metal stamping, wood and stone Machinery,

glass and door and window machinery, injection molding machines, manipulators, robots, construction machinery, heavy machinery

factories, automobile manufacturing, lifting and transportation equipment, automated warehouses, docks, fire trucks and other

indoor and outdoor environments.

Technical Parameter High Flexible Towline Cables With Shield

|

Standard

|

Comply with EU RoHS and Reach regulations

|

|||

|

Conductor

|

adopts high-quality tinned copper stranded copper wire

|

|||

|

Insulation material

|

Special PVC sheath with high flexibility

|

|||

|

Temperature range:

|

Mobile installation -5°C to +70°c Fixed installation -15°C to +80°c

|

|||

|

Insulation resistance:

|

Minimum 20 MOhm x km

|

|||

|

Color

|

Black (other colors can be customized)

|

|||

|

Minimum bending radius:

|

Mobile installation 7.5×cable diameter Fixed installation 6x cable diameter

|

|||

|

Nominal voltage

|

Uo/U 300/300 V

|

|||

|

Test voltage

|

1500 V

|

|||

|

Application:

|

Suitable for various non-standard automated production equipment such as CNC machine tools, industrial robots, servo drives,

woodworking machinery, mask machines, manipulators, dispensing machines, laser equipment, stamping lines, logistics automation, ceramic production equipment, etc., which can withstand long-term acceleration, Deceleration, tensile and compressive stress, and high-speed periodic bending, and always maintain high stability. |

|||

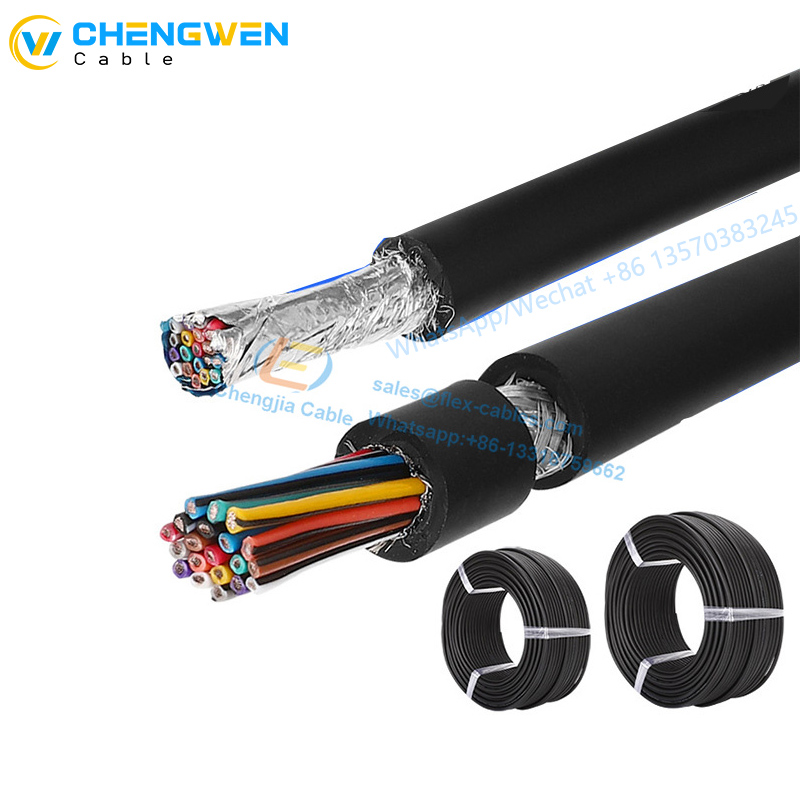

High Flexible Towline Cables With Shield Structure

1. Tinned copper (less than 0.5m㎡) or bare copper (0.5m㎡ and above) conductor thin copper wire, in line with DIN VDE 0295 category 6 and IEC60228 Class 6

2. Special PVC insulation

3. Color core wire identification (less than 0.5m㎡)

4. Black core wire, with continuous white digital code (0.5m㎡ and above), yellow-green ground wire on the outer layer (3 core and above)

5. The wire core is stranded in layers with the best pitch

6. Improved tinned copper wire braided shield

7. The minimum coverage rate is 80%

8. Special PVC outer sheath

9. Black (RAL 9005) matte

|

No.

|

Product Code

|

Cores Number and cross-sectional area

(NO.Xm㎡)

|

Approximate outer diameter (mm)

|

Outer sheath color

|

20℃ Conductor DC resistance

Ω/km

|

|

1

|

YY502.02.0020

|

2×0.2

|

4.4

|

Black

|

95

|

|

2

|

YY502.03.0020

|

3×0.2

|

4.6

|

Black

|

95

|

|

3

|

YY502.04.0020

|

4×0.2

|

4.9

|

Black

|

95

|

|

4

|

YY502.05.0020

|

5×0.2

|

5.2

|

Black

|

95

|

|

5

|

YY502.06.0020

|

6×0.2

|

5.6

|

Black

|

95

|

|

6

|

YY502.08.0020

|

8×0.2

|

6.5

|

Black

|

95

|

|

7

|

YY502.10.0020

|

10×0.2

|

7.4

|

Black

|

95

|

|

8

|

YY502.12.0020

|

12×0.2

|

7.0

|

Black

|

95

|

|

9

|

YY502.16.0020

|

16×0.2

|

7.8

|

Black

|

95

|

|

10

|

YY502.20.0020

|

20×0.2

|

8.5

|

Black

|

95

|

|

11

|

YY502.02.0030

|

2×0.3

|

4.6

|

Black

|

71.2

|

|

12

|

YY502.03.0030

|

3×0.3

|

4.8

|

Black

|

71.2

|

|

13

|

YY502.04.0030

|

4×0.3

|

5.2

|

Black

|

71.2

|

|

14

|

YY502.05.0030

|

5×0.3

|

5.5

|

Black

|

71.2

|

|

15

|

YY502.06.0030

|

6×0.3

|

5.8

|

Black

|

71.2

|

|

16

|

YY502.08.0030

|

8×0.3

|

6.8

|

Black

|

71.2

|

|

17

|

YY502.10.0030

|

10×0.3

|

7.8

|

Black

|

71.2

|

|

18

|

YY502.12.0030

|

12×0.3

|

7.4

|

Black

|

71.2

|

|

19

|

YY502.16.0030

|

16×0.3

|

8.2

|

Black

|

71.2

|

|

20

|

YY502.20.0030

|

20×0.3

|

9.0

|

Black

|

71.2

|

|

MOQ 1 meter, If you need to order PUR outer sheath, MOQ 400 meters

|

|||||

Company Profile

Chengwen specializes in the development and manufacturing of high-end special wire and cable. Use the best raw

material & Provide the best service, so as to guarantee the cables’stable performance under longtime extremely

harsh working conditions. Chengjia offers our customers the highest quality products, which complys with UL,

CE,TUV,3C Certifications and our factory successfully obtained ISO 9001:2000.