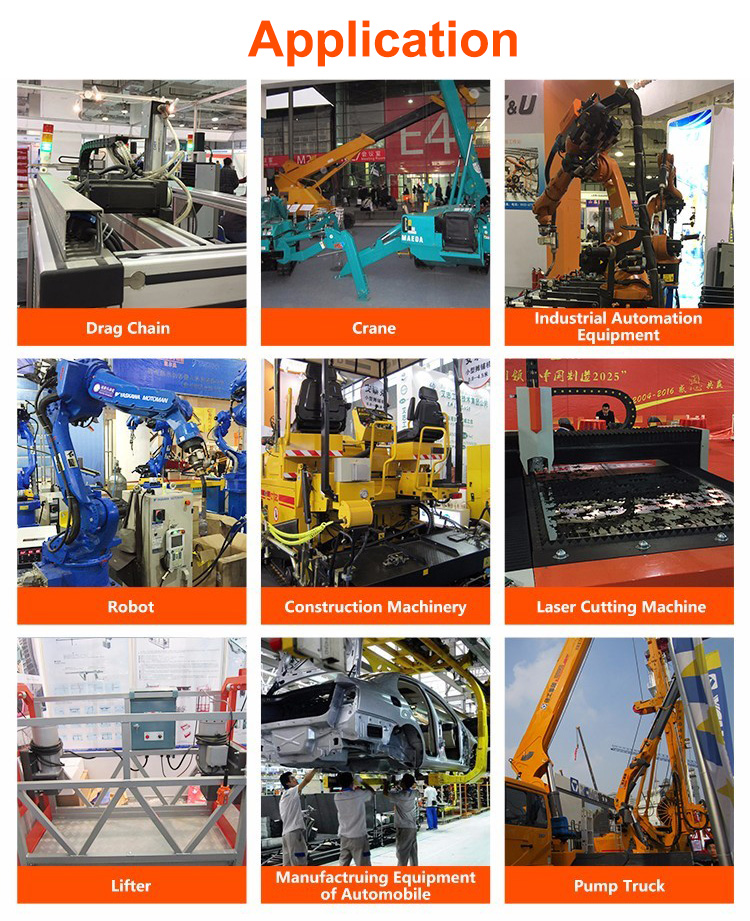

Application

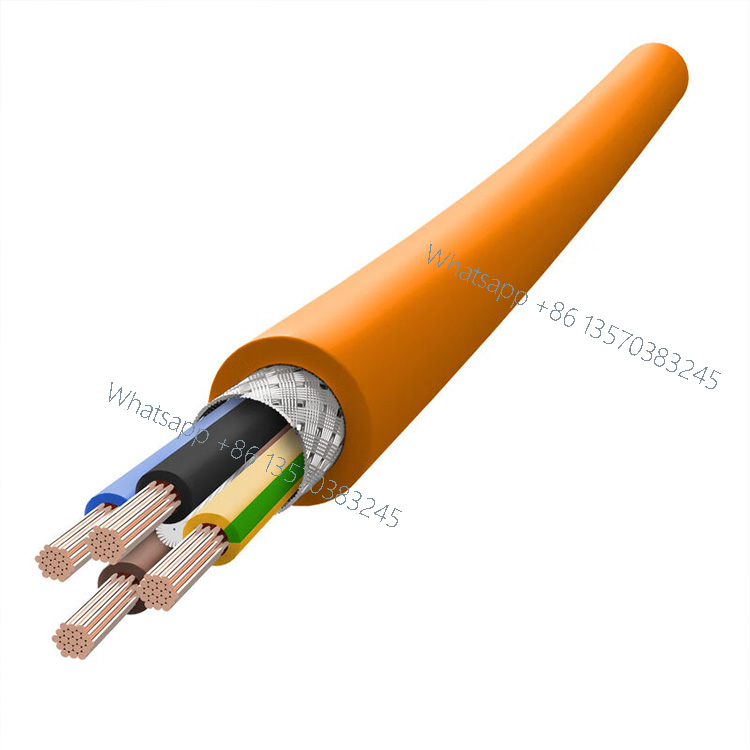

Cable Structure

| Item | Product Code | Number of Cores and Cross-Sectional Area | Approximate Outer Diameter | Color | Product Number | MOQ |

| 1 | TP1008.02.0075 | 2×0.75 | 6.30 | orange | C-2300 | |

| 2 | TP1008.04.0050 | 4G0.5 | 6.60 | orange | C-2301 | |

| 3 | TP1008.04.0075 | 4G0.75 | 7.20 | orange | C-2302 | |

| 4 | TP1008.04.0100 | 4G1.0 | 7.80 | orange | C-2303 | |

| 5 | TP1008.04.0150 | 4G1.5 | 8.50 | orange | C-2304 | |

| 6 | TP1008.04.0250 | 4G2.5 | 10.00 | orange | C-2305 | ※ |

| 7 | TP1008.04.0400 | 4G4.0 | 11.50 | orange | C-2306 | ※ |

| 8 | TP1008.04.0600 | 4G6.0 | 13.50 | orange | C-2307 | ※ |

| 9 | TP1008.04.1000 | 4G10.0 | 18.00 | orange | C-2308 | ※ |

| 10 | TP1008.04.1600 | 4G16.0 | 22.40 | orange | C-2309 | ※ |

| 11 | TP1008.04.2500 | 4G25.0 | 26.20 | orange | C-2310 | ※ |

| 12 | TP1008.04.3500 | 4G35.0 | 30.00 | orange | C-2311 | ※ |

| 13 | TP1008.06.1920 | 4G0.75+(2×0.5+B) | 8.70 | orange | C-2312 | |

| 14 | TP1008.06.1719 | 4G1.0+(2×0.75+B) | 9.60 | orange | C-2314 | |

| 15 | TP1008.06.1519 | 4G1.5+(2×0.75+B) | 10.40 | orange | C-2315 | ※ |

| 16 | TP1008.06.1319 | 4G2.5+(2×0.75+B) | 11.80 | orange | C-2317 | ※ |

| 17 | TP1008.06.1315 | 4G2.5+(2×1.5+B) | 12.50 | orange | C-2319 | ※ |

| 18 | TP1008.06.1115 | 4G4.0+(2×1.5+B) | 14.40 | orange | C-2321 | ※ |

| 19 | TP1008.06.0915 | 4G6.0+(2×1.5+B) | 16.30 | orange | C-2323 | ※ |

| 20 | TP1008.06.0715 | 4G10.0+(2×1.5+B) | 19.60 | orange | C-2325 | ※ |

| 21 | TP1008.06.0515 | 4G16.0+(2×1.5+B) | 23.60 | orange | C-2327 | ※ |

| 22 | TP1008.06.0315 | 4G25.0+(2×1.5+B) | 28.00 | orange | C-2328 | ※ |

| 23 | TP1008.06.0215 | 4G35.0+(2×1.5+B) | 31.50 | orange | C-2329 |