Polyurethane (PUR) DRAG CHAIN CONTROL CABLE Parameter

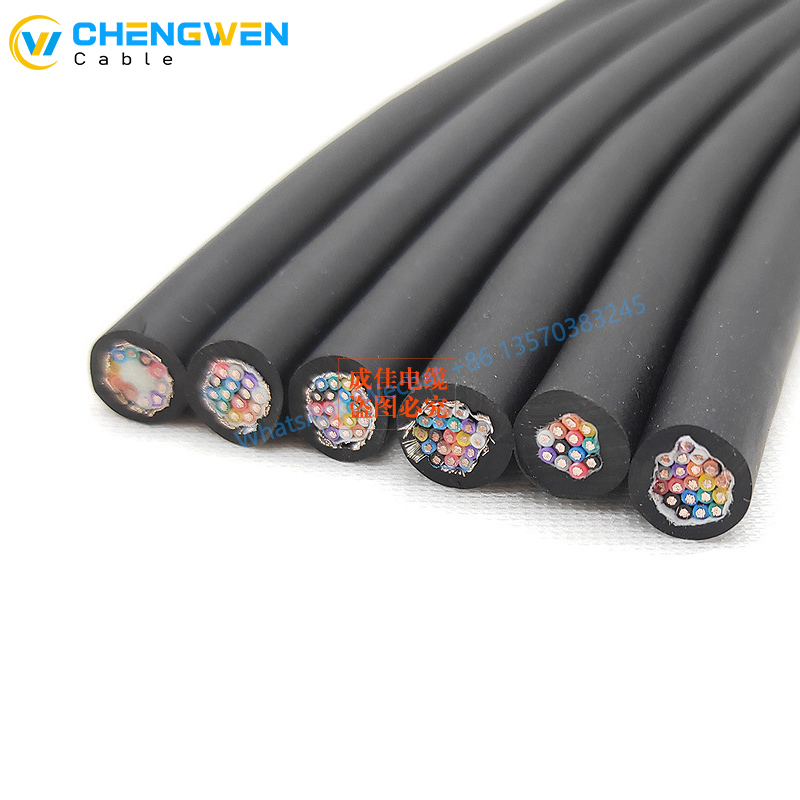

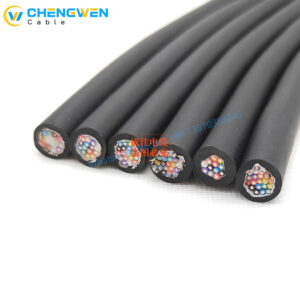

| No. | Product Code | Cores Number and cross-sectional area | Approximate outer diameter (mm) | Outer sheath color |

| (NO.Xm㎡) | ||||

| 1 | YP501.02.0014 | 2×0.14 | 3.6 | Black/Grey |

| 2 | YP501.03.0014 | 3×0.14 | 3.8 | Black/Grey |

| 3 | YP501.04.0014 | 4×0.14 | 4.2 | Black/Grey |

| 4 | YP501.06.0014 | 6×0.14 | 4.8 | Black/Grey |

| 5 | YP501.08.0014 | 8×0.14 | 5.6 | Black/Grey |

| 6 | YP501.10.0014 | 10×0.14 | 6.4 | Black/Grey |

| 7 | YP501.12.0014 | 12×0.14 | 6.1 | Black/Grey |

| 8 | YP501.16.0014 | 16×0.14 | 6.8 | Black/Grey |

| 9 | YP501.20.0014 | 20×0.14 | 7.4 | Black/Grey |

| 10 | YP501.02.0020 | 2×0.2 | 3.8 | Black/Grey |

| 11 | YP501.03.0020 | 3×0.2 | 4.0 | Black/Grey |

| 12 | YP501.04.0020 | 4×0.2 | 4.5 | Black/Grey |

| 13 | YP501.05.0020 | 5×0.2 | 4.8 | Black/Grey |

| 14 | YP501.06.0020 | 6×0.2 | 5.2 | Black/Grey |

| 15 | YP501.08.0020 | 8×0.2 | 6.0 | Black/Grey |

| 16 | YP501.10.0020 | 10×0.2 | 6.8 | Black/Grey |

| 17 | YP501.12.0020 | 12×0.2 | 6.4 | Black/Grey |

| 18 | YP501.16.0020 | 16×0.2 | 7.2 | Black/Grey |

| 19 | YP501.20.0020 | 20×0.2 | 8.0 | Black/Grey |

| 20 | YP501.24.0020 | 24×0.2 | 8.8 | Black/Grey |

| 21 | YP501.26.0020 | 26×0.2 | 9.2 | Black/Grey |

| 22 | YP501.02.0030 | 2×0.3 | 4.2 | Black/Grey |

| 23 | YP501.03.0030 | 3×0.3 | 4.4 | Black/Grey |

| 24 | YP501.04.0030 | 4×0.3 | 4.8 | Black/Grey |

| 25 | YP501.05.0030 | 5×0.3 | 5.2 | Black/Grey |

| 26 | YP501.06.0030 | 6×0.3 | 5.5 | Black/Grey |

| 27 | YP501.07.0030 | 7×0.3 | 5.8 | Black/Grey |

| 28 | YP501.08.0030 | 8×0.3 | 6.5 | Black/Grey |

| 29 | YP501.10.0030 | 10×0.3 | 7.3 | Black/Grey |

| 30 | YP501.12.0030 | 12×0.3 | 7.0 | Black/Grey |

| 31 | YP501.16.0030 | 16×0.3 | 7.8 | Black/Grey |

| 32 | YP501.20.0030 | 20×0.3 | 8.5 | Black/Grey |

| 33 | YP501.24.0030 | 24×0.3 | 9.6 | Black/Grey |

| 34 | YP501.26.0030 | 26×0.3 | 10.0 | Black/Grey |

| 35 | YP501.30.0030 | 30×0.3 | 10.0 | Black/Grey |

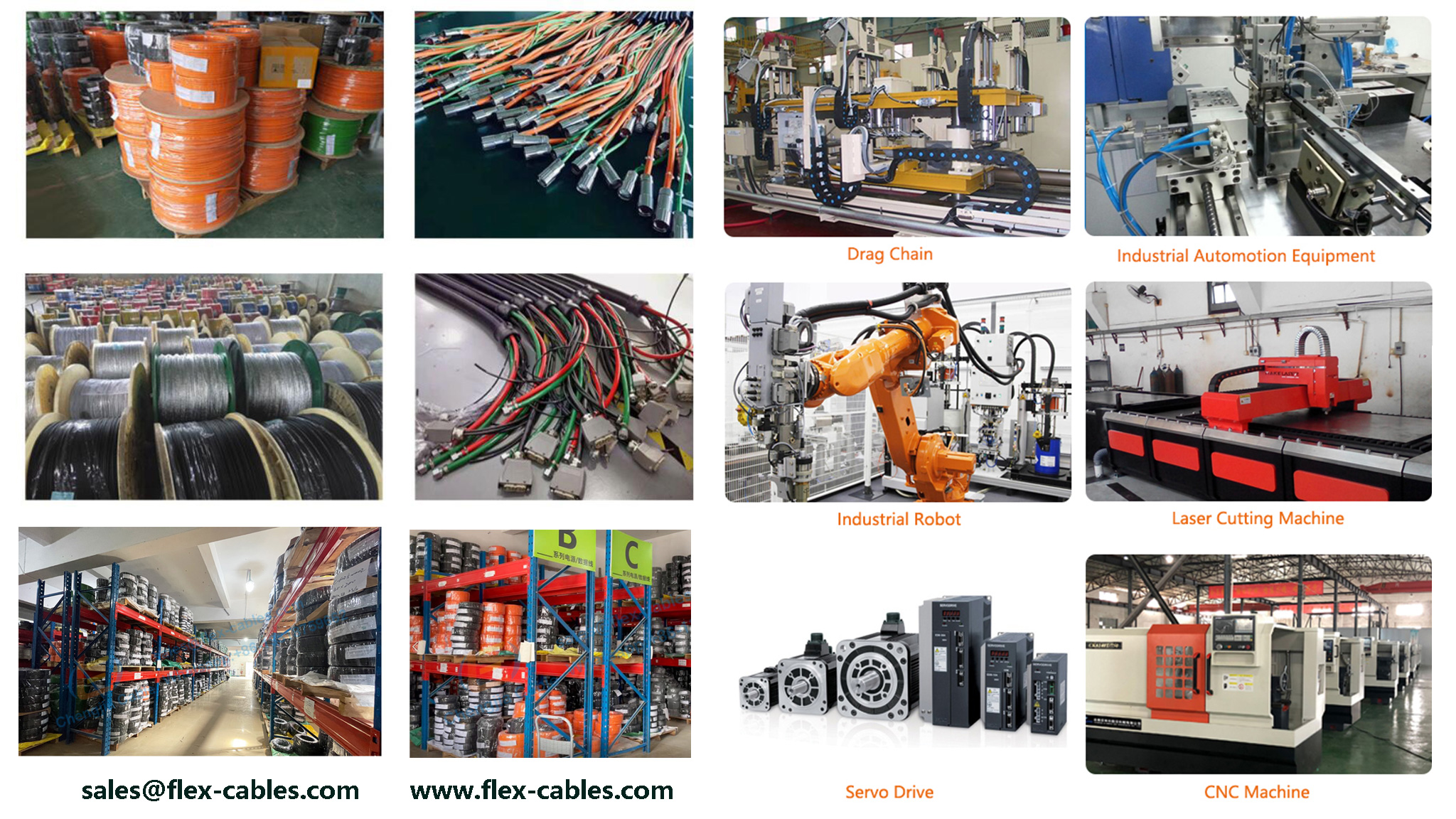

Polyurethane (PUR) DRAG CHAIN CONTROL CABLE Technical data

●Specialized PUR sheath, highly flexible

●Temperature range: Mobile installation: -20°C to +80°C Fixed installation: -40°C to +90°C

●Maximum overhead/sliding speed 5 m/s, 3 m/s

●Maximum acceleration 50 m/s

●Nominal voltage Uo/U: 300/300V

●Test voltage: 1500V

●Insulation resistance: Minimum 20 MOhmxkm

●Minimum bending radius: Mobile installation: 7.5 x cable diameter Fixed installation: 6 x cable diameter

●Complies with EU RoHS and Reach regulation

●Oil resistance Totally oil resistant

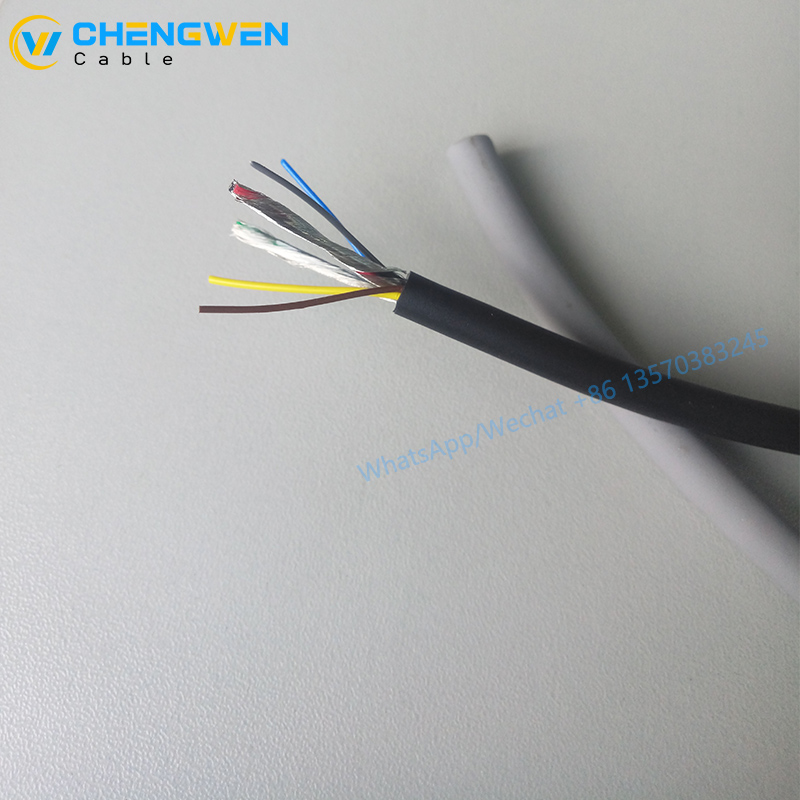

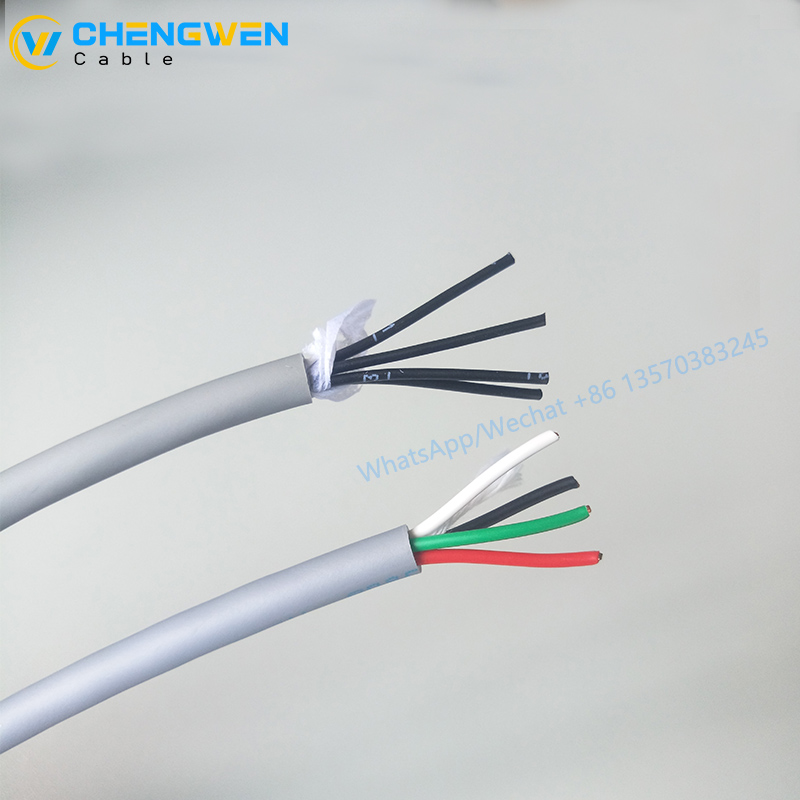

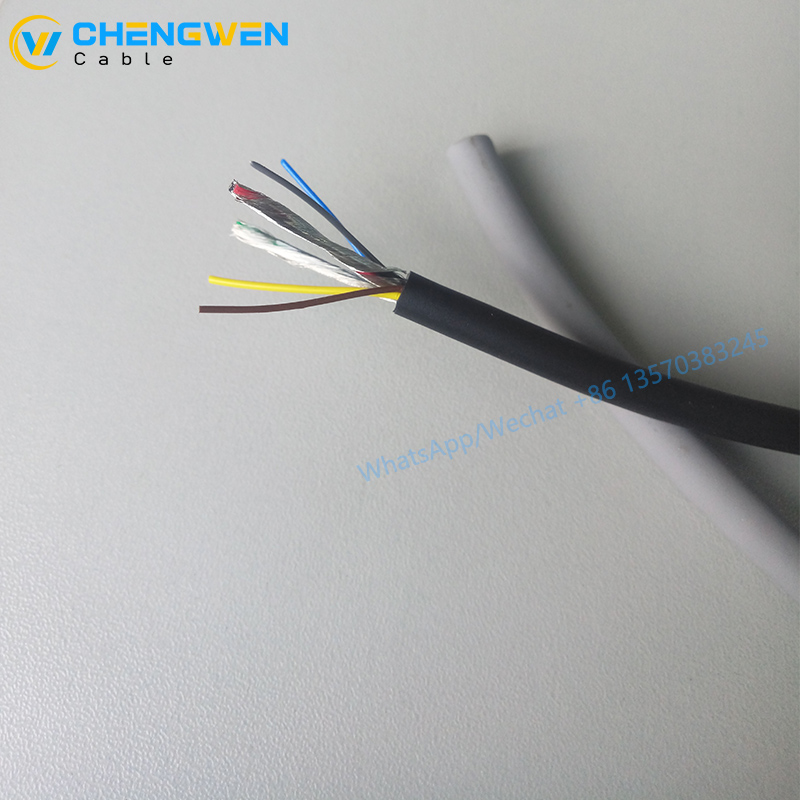

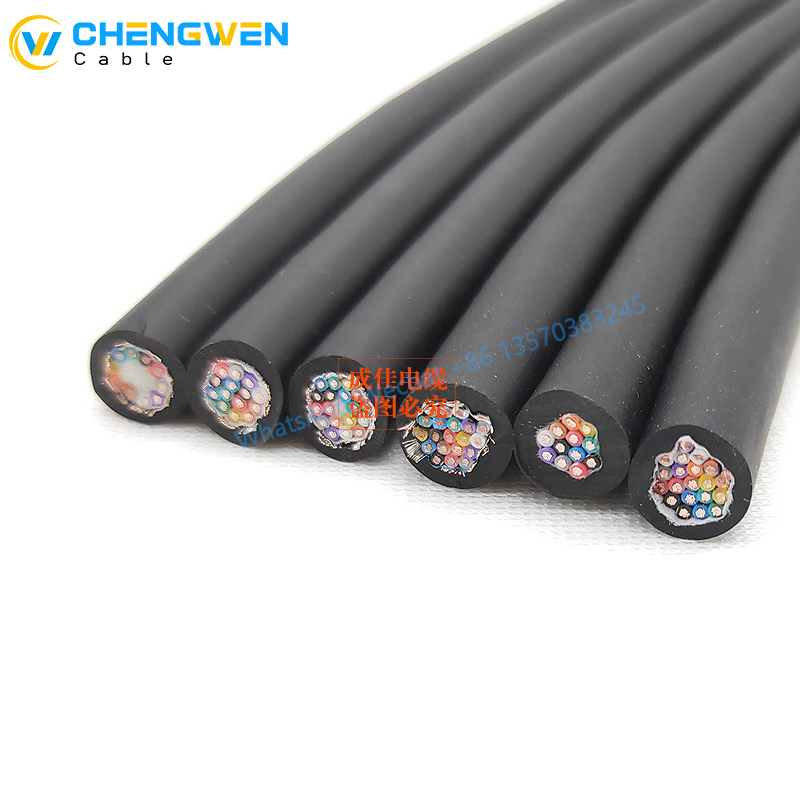

Polyurethane (PUR) DRAG CHAIN CONTROL CABLE Structure:

●Tinned copper conductor, fine copper wire

●Compliant with DIN VDE 0295 Class 6 and IEC 60228 Class 6

●Specialized PVC insulation

●Color-coded core wire identification

●Optimal lay length layered stranding of the cores

●Outer sheath Low-adhesion PUR mixture, adjusted to meet the requirements of the drag chain.

●Color: gray, black,or can be color-matched according to customer requirements.

| High Flexibility 5 Million Times Drag Chain Cable Test Standards | ||

| Drag Chain Bending Test Test Method: Take a 2-meter finished cable, with a bending radius of 6 times the outer diameter of the cable, a moving stroke of 900 mm, and reciprocating movement at a speed of 90 times/minute. |

Two-Wheel Winding Test Test Method: Take a 5-meter finished cable, according to the specified pulley diameter and weight of the weights. The pulley moves at a speed of 0.33 m/sec, and the moving distance is more than 1.0 meter under reciprocating conditions |

90-Degree Bend Test Test Method: Take a 2-meter finished cable, with a bending radius of 2.5 times the outer diameter of the cable, according to the standard specified weight of the weights, bending at a speed of 40 times/minute |

| Judgment Criteria: 1. The number of reciprocations exceeds 5,000,000 times without open circuit or short circuit. 2. The sheath is not broken | Judgment Criteria: 1. The number of reciprocations exceeds 200,000 times without open circuit or short circuit. 2. The sheath is not broken | Judgment Criteria: 1. The number of reciprocations exceeds 100,000 times without open circuit or short circuit. 2. The sheath is not broken |