High Flexible Drag Chain Data Tpu Cable

| YP506 HIGH FLEXIBLE PUR DRAG CHAIN DATA CABLE ( 5 million times reliability tests for drag chain) | ||||

| No. | Product Code | Cores Number and cross-sectional area | Approximate outer diameter (mm) | Outer sheath color |

| (NO.Xm㎡) | ||||

| 1 | YP506.04.0014 | 2x2x0.14 | 5.5 | Black |

| 2 | YP506.06.0014 | 3x2x0.14 | 6.0 | Black |

| 3 | YP506.08.0014 | 4x2x0.14 | 6.6 | Black |

| 4 | YP506.10.0014 | 5x2x0.14 | 7.0 | Black |

| 5 | YP506.12.0014 | 6x2x0.14 | 7.4 | Black |

| 6 | YP506.14.0014 | 7x2x0.14 | 7.8 | Black |

| 7 | YP506.16.0014 | 8x2x0.14 | 8.2 | Black |

| 8 | YP506.20.0014 | 10x2x0.14 | 9.2 | Black |

| 9 | YP506.26.0014 | 13x2x0.14 | 9.8 | Black |

| 10 | YP506.04.0020 | 2x2x0.2 | 6.0 | Black/ Green |

| 11 | YP506.06.0020 | 3x2x0.2 | 6.4 | Black/ Green |

| 12 | YP506.08.0020 | 4x2x0.2 | 7.0 | Black/ Green |

| 13 | YP506.10.0020 | 5x2x0.2 | 7.5 | Black/ Green |

| 14 | YP506.12.0020 | 6x2x0.2 | 8.2 | Black/ Green |

| 15 | YP506.14.0020 | 7x2x0.2 | 8.5 | Black |

| 16 | YP506.16.0020 | 8x2x0.2 | 9.0 | Black |

| 17 | YP506.20.0020 | 10x2x0.2 | 10.0 | Black |

| 18 | YP506,26,0020 | 13x2x0.2 | 10.5 | Black |

| 19 | YP506.04.0030 | 2x2x0.3 | 6.2 | Black |

| 20 | YP506.06.0030 | 3x2x0.3 | 6.6 | Black |

| 21 | YP506.08.0030 | 4x2x0.3 | 7.5 | Black |

| 22 | YP506.10.0030 | 5x2x0.3 | 7.8 | Black |

| 23 | YP506.12.0030 | 6x2x0.3 | 8.6 | Black |

| 24 | YP506.14.0030 | 7x2x0.3 | 9.0 | Black |

| 25 | YP506.16.0030 | 8x2x0.3 | 9.5 | Black |

| 26 | YP506.26.0030 | 13x2x0.3 | 11.2 | Black |

High Flexible Drag Chain Data Tpu Cable Technical data

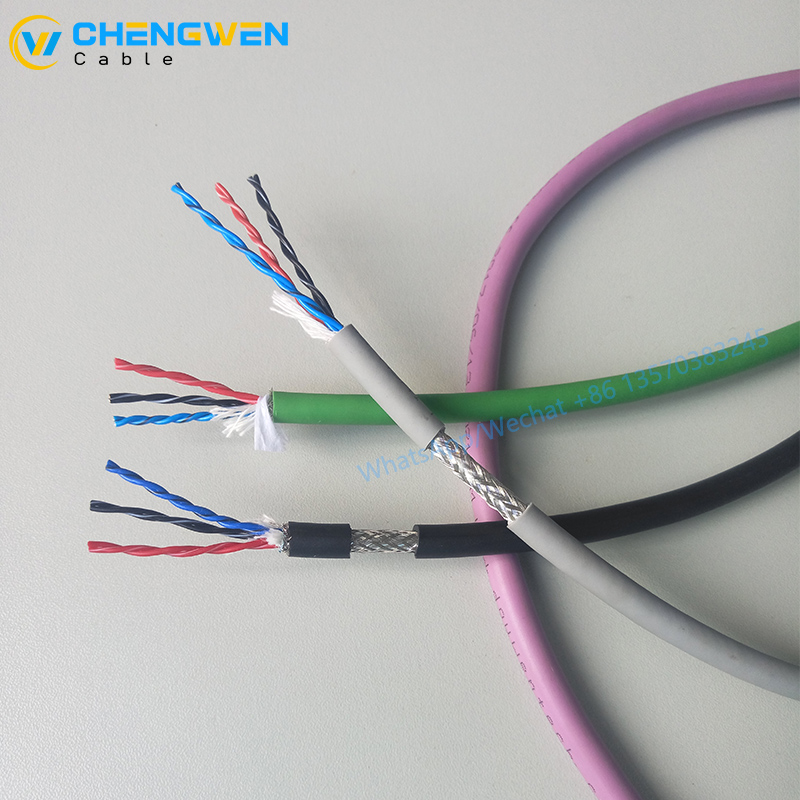

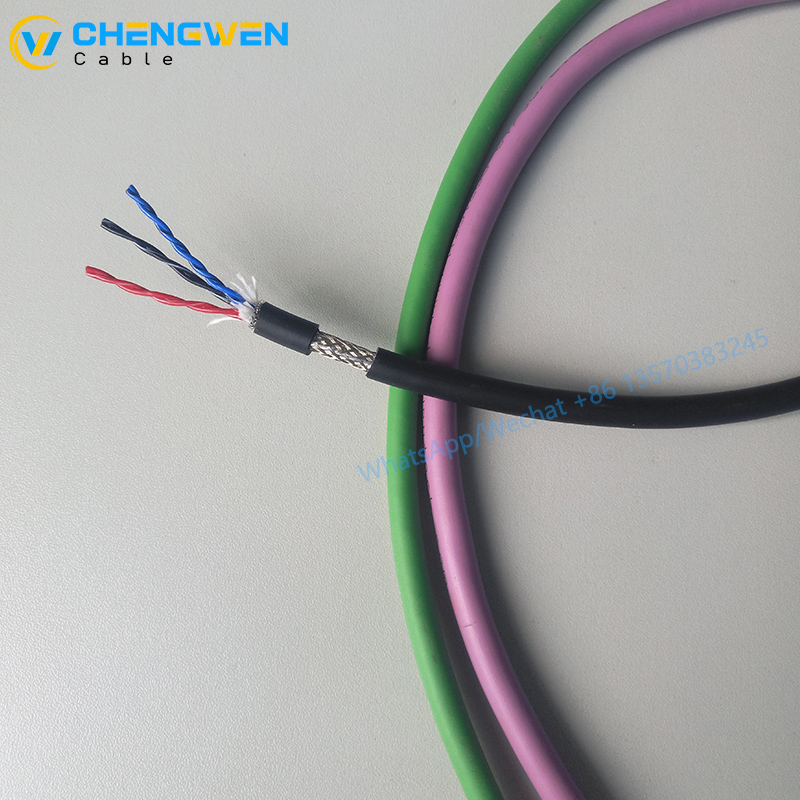

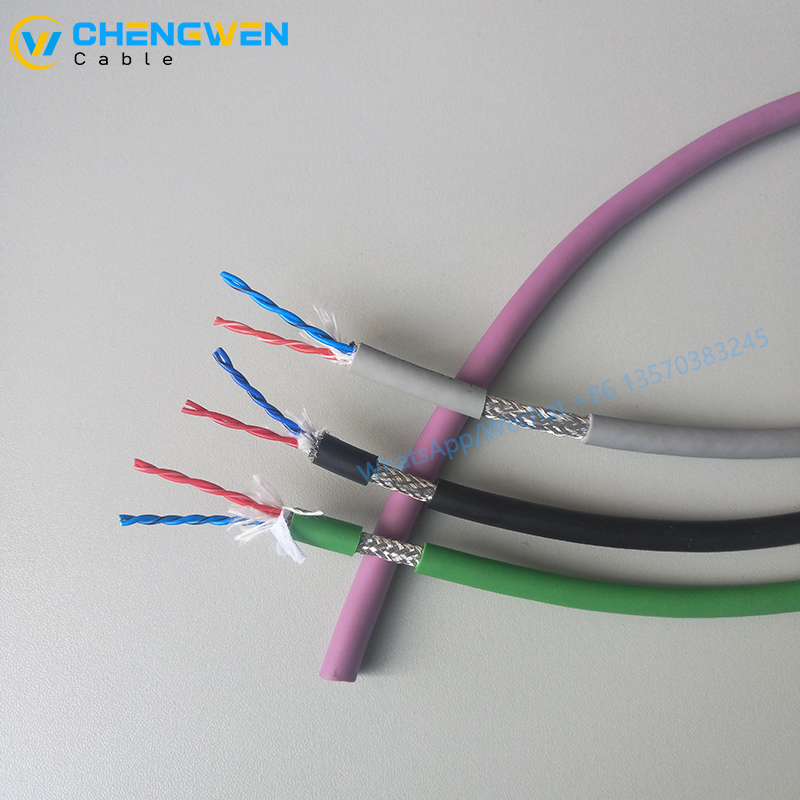

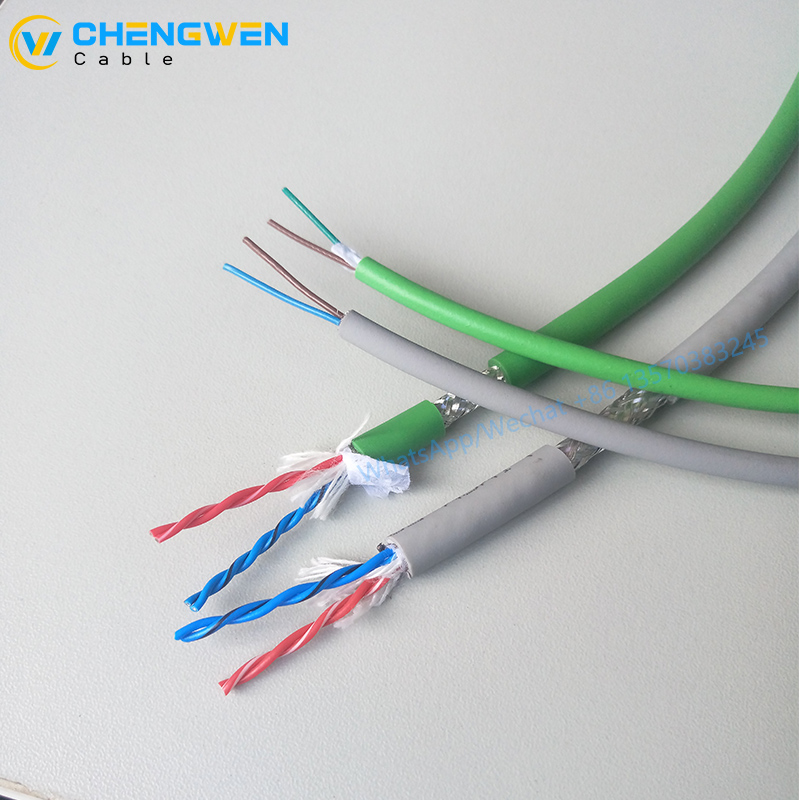

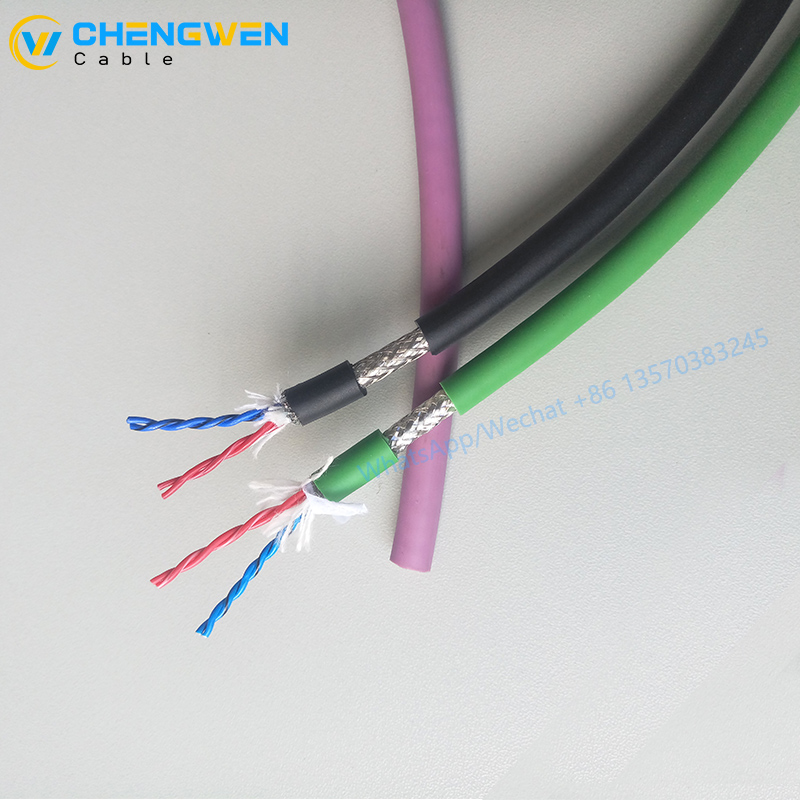

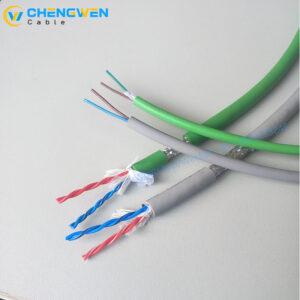

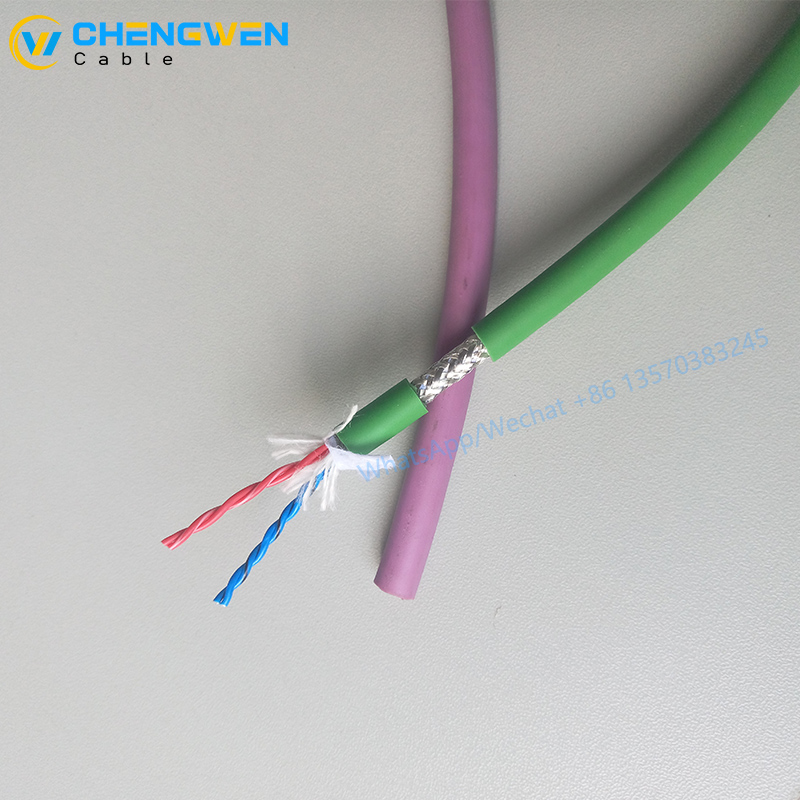

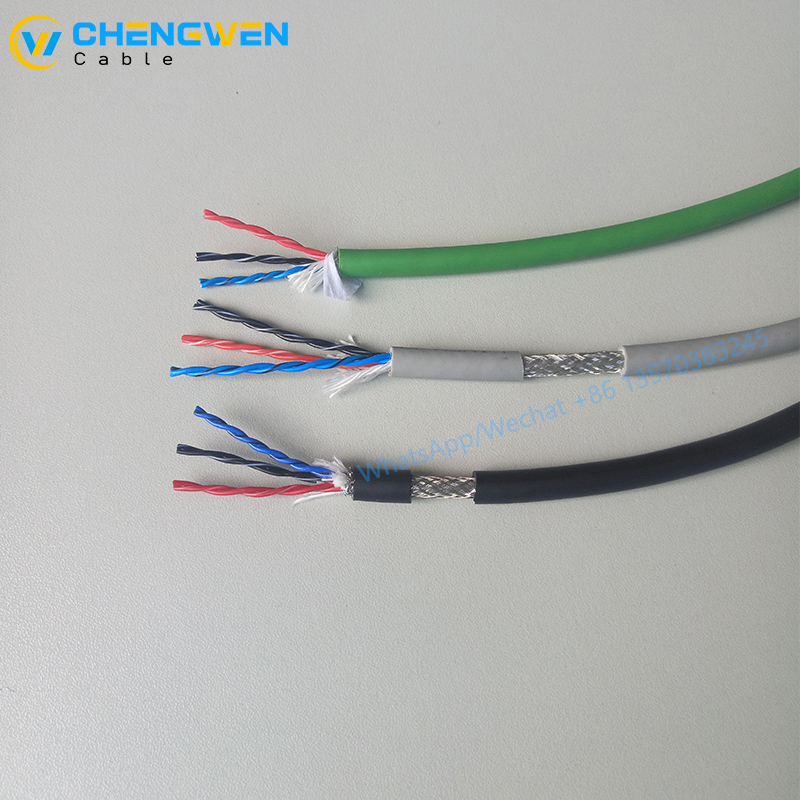

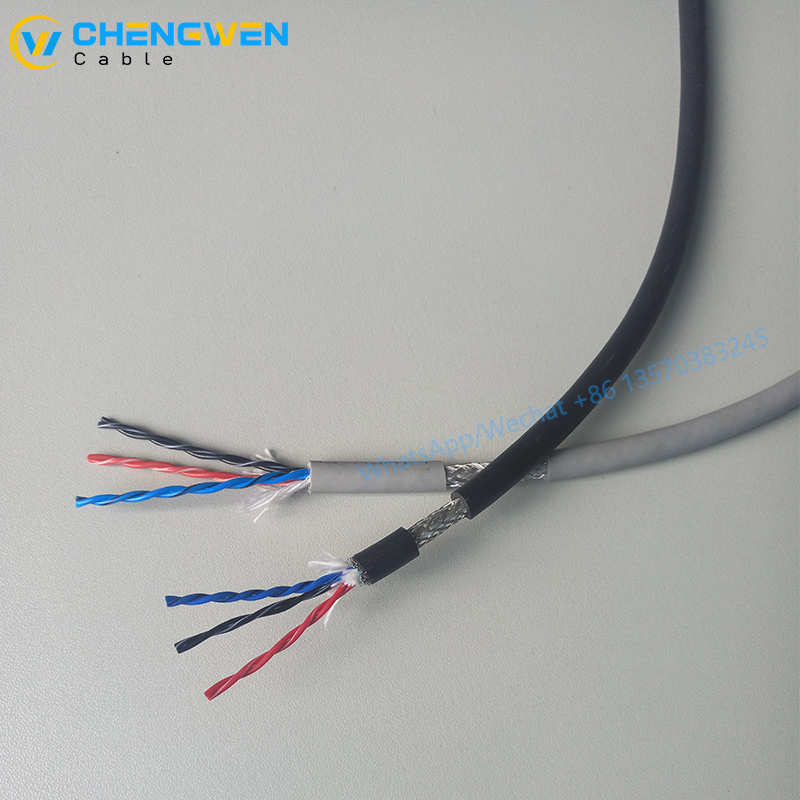

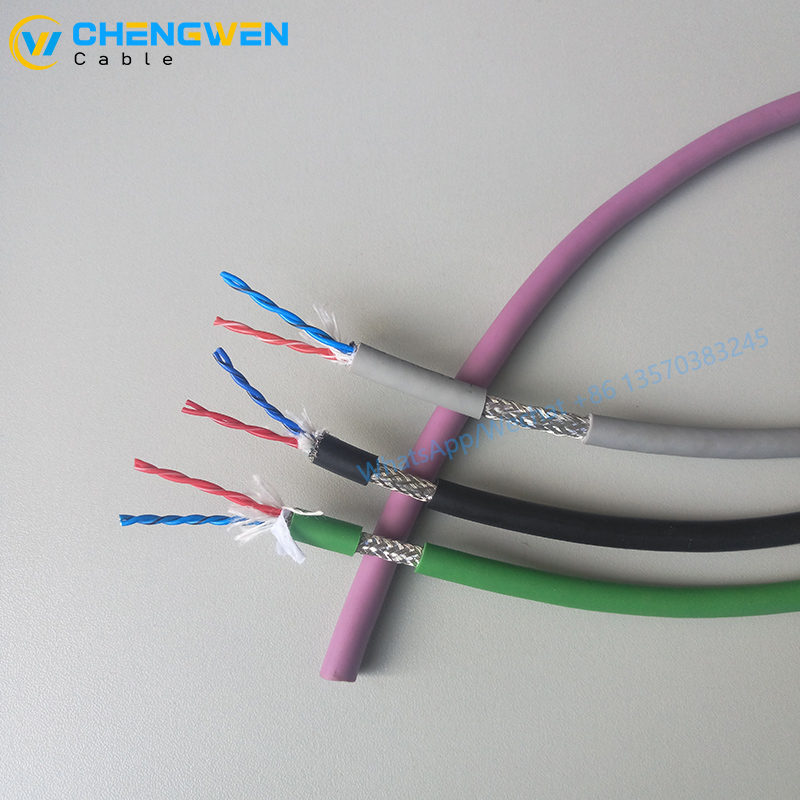

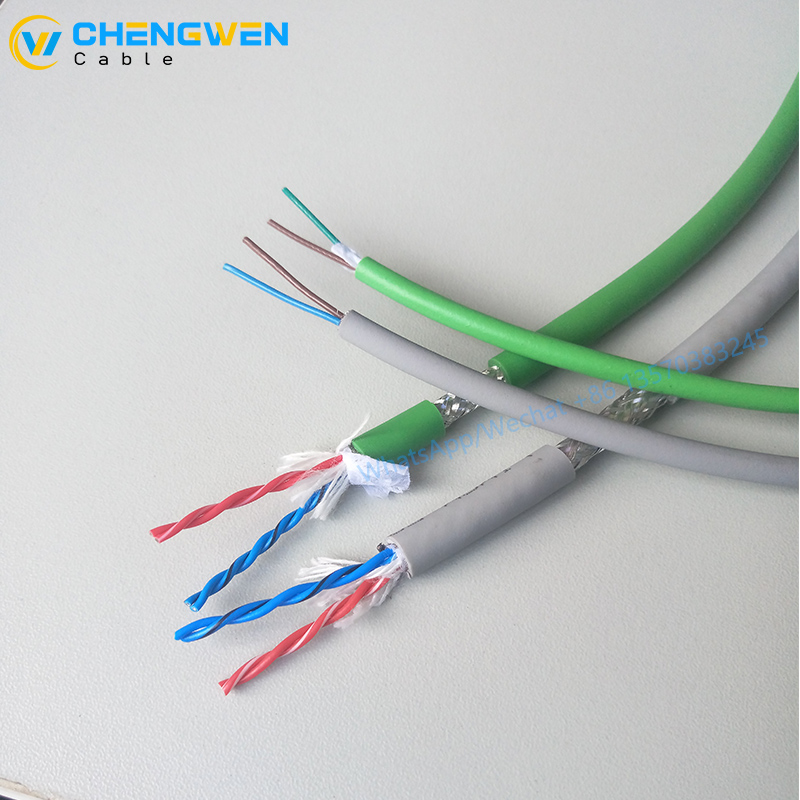

High Flexible Drag Chain Data Tpu Cable Structure

●Tinned copper (below 0.5mm²) or bare copper (0.5mm² and above) conductors Fine copper wire, compliant with DIN VDE 0295 Class 6 and IEC 60228 Class 6

●Special PVC insulation

●Color-coded cores (below 0.5mm²)

●Black cores with continuous white numeric marking (0.5mm² and above)

●Stranded cores with optimal pitch twisting

●Enhanced tinned copper wire braided shielding

●Minimum overall shielding coverage of 85%

●Low friction, wear-resistant, low-temperature resistant, and oil-resistant PUR composite material.

●Grey,green, black, or color can be customized according to customer requirements.

| High Flexibility 5 Million Times Drag Chain Cable Test Standards | ||

| Drag Chain Bending Test Test Method: Take a 2-meter finished cable, with a bending radius of 6 times the outer diameter of the cable, a moving stroke of 900 mm, and reciprocating movement at a speed of 90 times/minute. |

Two-Wheel Winding Test Test Method: Take a 5-meter finished cable, according to the specified pulley diameter and weight of the weights. The pulley moves at a speed of 0.33 m/sec, and the moving distance is more than 1.0 meter under reciprocating conditions |

90-Degree Bend Test Test Method: Take a 2-meter finished cable, with a bending radius of 2.5 times the outer diameter of the cable, according to the standard specified weight of the weights, bending at a speed of 40 times/minute |

| Judgment Criteria: 1. The number of reciprocations exceeds 5,000,000 times without open circuit or short circuit. 2. The sheath is not broken | Judgment Criteria: 1. The number of reciprocations exceeds 200,000 times without open circuit or short circuit. 2. The sheath is not broken | Judgment Criteria: 1. The number of reciprocations exceeds 100,000 times without open circuit or short circuit. 2. The sheath is not broken |