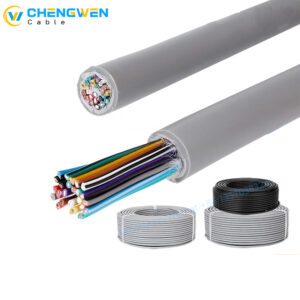

300V UL2517 Robot Flexible Oil Resistant Multicore Flexible Cable

This cable is particularly suitable for continuous ultra-high flexibility and high-speed bending applications in mechanical equipment and machine tools. The ultra-high flexibility cable utilizes specially modified insulation and jacket materials, providing excellent resistance to wear and media. It can withstand prolonged acceleration, deceleration, tension, compression stresses, as well as millions of cycles of periodic bending, while maintaining high stability.

| UL20276 80 DEGREE HIGH FLEX ENCODER CABLE (AMERICAN CORE WIRE) (30 million times reliability tests for drag chain) | ||||

| No. | Product Code | Cores Number and cross-sectional area | Approximate outer diameter (mm) | Outer sheath color |

| (NO.Xm㎡) | ||||

| 1 | MC-YY3006.04.0014 | 2x2x0.14 | 5.9 | Black |

| 2 | MC-YY3006.06.0014 | 3x2x0.14 | 5.9 | Black |

Oil Resistant Multicore Flexible Cable Technical Parameter

●Special PVC sheath with ultra-high flexibility.

●Temperature range: Mobile installation: -5°C to +70°C. Fixed installation: -15°C to +80°C.

●Nominal voltage Uo/U: 300/300V.

●Test voltage: 1500V.

●Minimum insulation resistance: 20 MOhmxkm.

●Minimum bending radius: Mobile installation: 6x cable diameter. Fixed installation: 4x cable diameter.

●Compliance with EU RoHS and Reach regulations.

Oil Resistant Multicore Flexible Cable Structure

Tin-plated copper conductor, fine copper wire in accordance with DIN VDE 0295 Class 6 and IEC60228 6 standards.

Special PVC insulation.

Color-coded core wire identification.

Optimum lay-up with twisted layers of conductors. Improved tin-plated copper wire braided shielding.

Minimum overall shielding coverage of 80%.

Special PVC outer sheath. Matte black (RAL 9005).