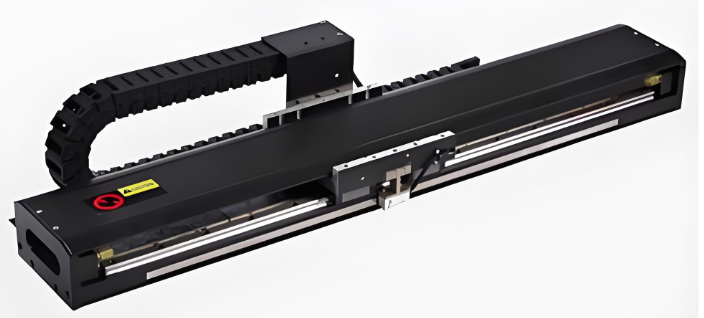

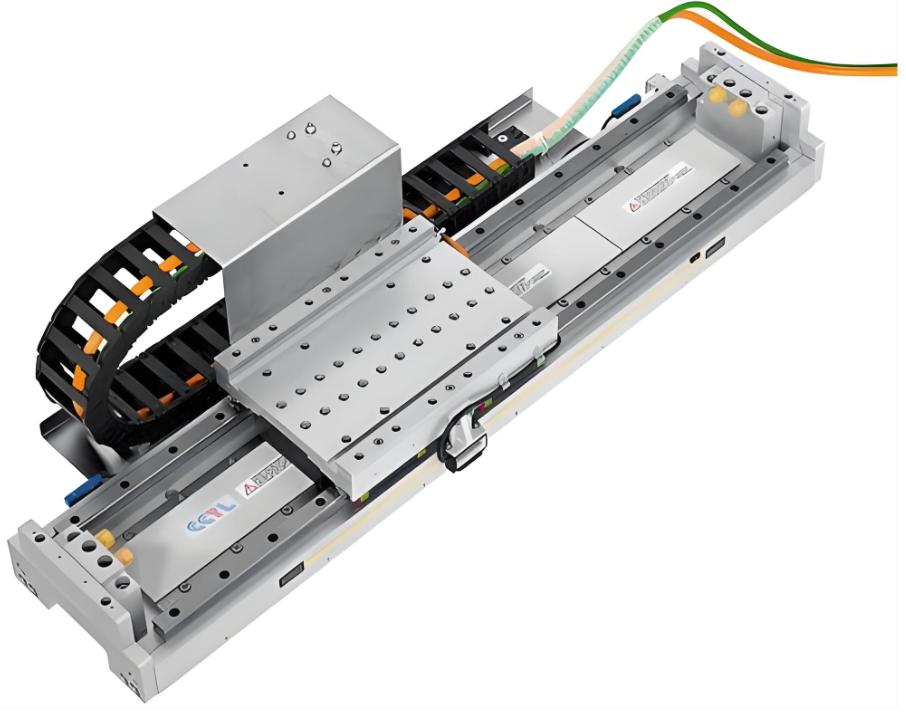

AC linear motor is a linear motor that uses AC power supply. Compared with general rotating motors, it has a simple structure, high positioning accuracy, fast response speed, high sensitivity, good follow-up performance, safe and reliable operation, long service life, few faults, and maintenance free. AC linear motors are mainly used in automatic control systems, devices that require large linear motion energy in a short time and short distance, and as drive motors for long-term continuous operation.

AC linear motors are widely used in film processing, light industry and chemical fiber, textile, cable, plastic and paper winding devices.

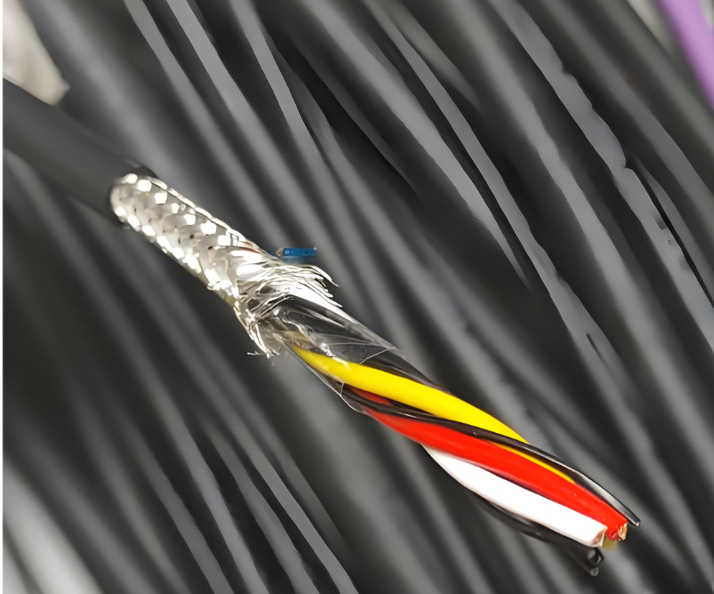

Linear motor cables are highly flexible cables specifically designed for linear motor systems, capable of withstanding high-frequency bending and twisting movements to ensure reliable signal and power transmission in high-speed, high-precision scenarios.

Key features include bend resistance (up to 50 million cycles), interference-shielded design, and oil/coolant-resistant materials, primarily used in industrial robots, CNC machine tools, and other automated equipment.

The specialized cable for linear motors is a special high flexibility drag chain cable that is suitable for high-speed reciprocating, high-speed acceleration, and high-precision signal transmission of linear motors. It has significant differences in structure, material, and performance compared to ordinary cables.

Core Structure and Materials of Linear Motor Cable

1.Conductor: Made of IEC 60228 Class 6/Class 5 ultra-fine multi stranded copper wire (often tin plated to prevent oxidation) to enhance bending fatigue resistance and reduce the risk of conductor fracture during movement;

2.Insulation: commonly used fluorine resins such as ETFE and FEP, high temperature resistance, chemical resistance, low friction, thin wall thickness;

3.Shielding: mostly woven with aluminum foil and high-density tinned copper wire (coverage ≥ 90%), some signal pairs adopt a double-layer structure of individual core wire shielding and total shielding to suppress the interference of strong electromagnetic fields of linear motors on encoder/feedback signals;

4.Sheath: Almost standard with PUR (polyurethane), wear-resistant, oil resistant, hydrolysis resistant, low temperature resistant, suitable for long-term drag chain movement;

5.Internal structure: Optimize pitch layering and twisting, ensure stable filling, and avoid core displacement and friction during movement.

Classification and Application Scenarios

1.Power cable: Conveying driving current, commonly 4 × 1.0 and 4 × 0.5 mm ², used for supplying power to the linear motor body;

2.Encoder/feedback cable: twisted pair multi-core shielded (e.g. 4 × 2 × 0.14 mm ²), transmitting grating ruler/magnetic grating position signals;

3.Composite cable: power+encoder+temperature sensor integrated(e.g. 4 × 0.5+4 × 2 × 0.14 mm ²) ,saving drag chain space.

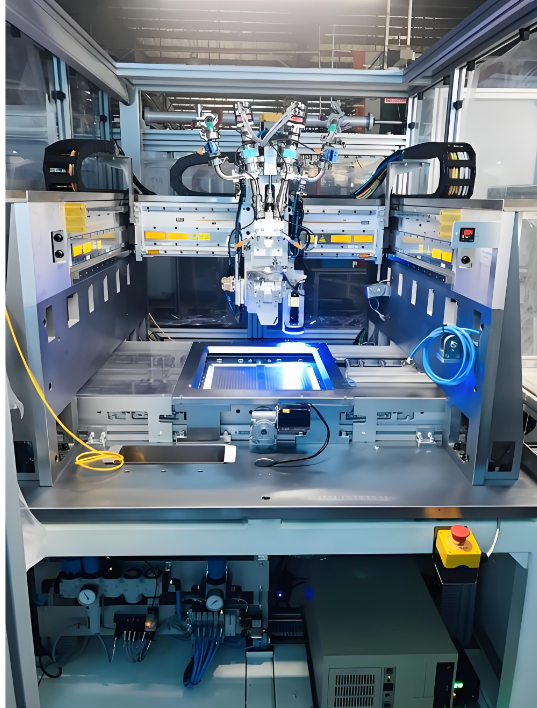

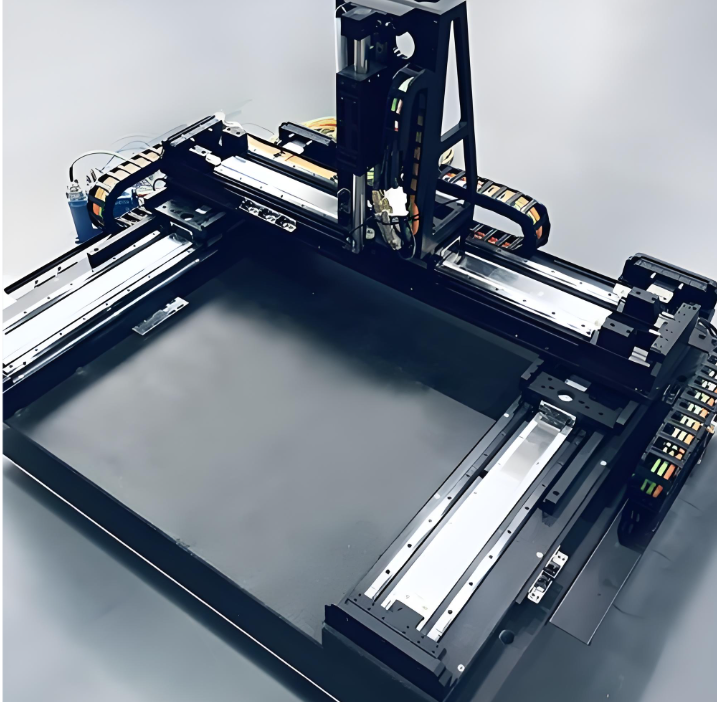

Typical applications: CNC machine tools, semiconductor equipment, high-speed automated production lines, laser processing machines, precision inspection platforms.

Internal structure: Optimize pitch layering and twisting, ensure stable filling, and avoid core displacement and friction during movement.

Key selection points

1.Determine the flexible wire movement speed/acceleration, stroke, and number of bends, and match the corresponding fatigue resistance level.

2.Calculate the cross-sectional area of the conductor based on current and wire length, and control the voltage drop;

3.The signal category must strengthen the shielding scheme (especially in strong electromagnetic environments);

4.Environment: Oil pollution, cutting fluid, temperature, UV radiation, corresponding to chemical/temperature resistant protective sheath;

5.Strictly follow the minimum bending radius (not less than the recommended value in the moving state) to avoid excessive bending and accelerated aging.

Installation and maintenance suggestions for flexible cord

1.Reserve appropriate slack insidflexible corde the drag chain to avoid excessive tension;

2.Avoid distortion, keep the fixed end parallel to the mobile end;

3.Regularly inspect the wear of the protective sheath and whether the shielding layer is damaged to prevent insulation breakdown and signal interference;

4.Special sealed connectors are used at the joints to prevent dust and cutting fluid from entering.