Temperature Range:

Moving inside the drag chain: +5°C to 80°C

Moving outside the drag chain: -5°C to 80°C

Bending Radius:

Moving inside the drag chain: Minimum 7.5xd

Moving outside the drag chain: Minimum 6xd

Drag Chain Life:

Factors affecting the service life of cables within the drag chain:

Temperature, Bending radius, Travel distance, Speed

TUV and Stable Drag Chain Testing Standards:

Temperature range: +15°C to 25°C

Bending radius: 7.5xd

Travel distance: 0.9 meters

Speed: 90 cycles/minute

The drag chain’s life can reach: 20 million cycle times

Maximum Speed and Acceleration:

Overhead: 8 m/s Sliding: 5 m/s Acceleration: 80 m/s²

Travel Distance:

For overhead applications, travel distance is less than 100 meters

Standard Voltage: 300/600V

Test Voltage: 3000V

Specifically designed for continuous high-intensity and high-speed bending applications of drag chains in mechanical equipment, machine tools, etc. Especially suitable for applications in high-speed, long-distance drag chains. The TY100.02 series drag chain cables have been widely used in indoor drag chain systems such as storage equipment, processing equipment, packaging equipment, indoor cranes, glass equipment, as well as in the packaging and logistics industries.

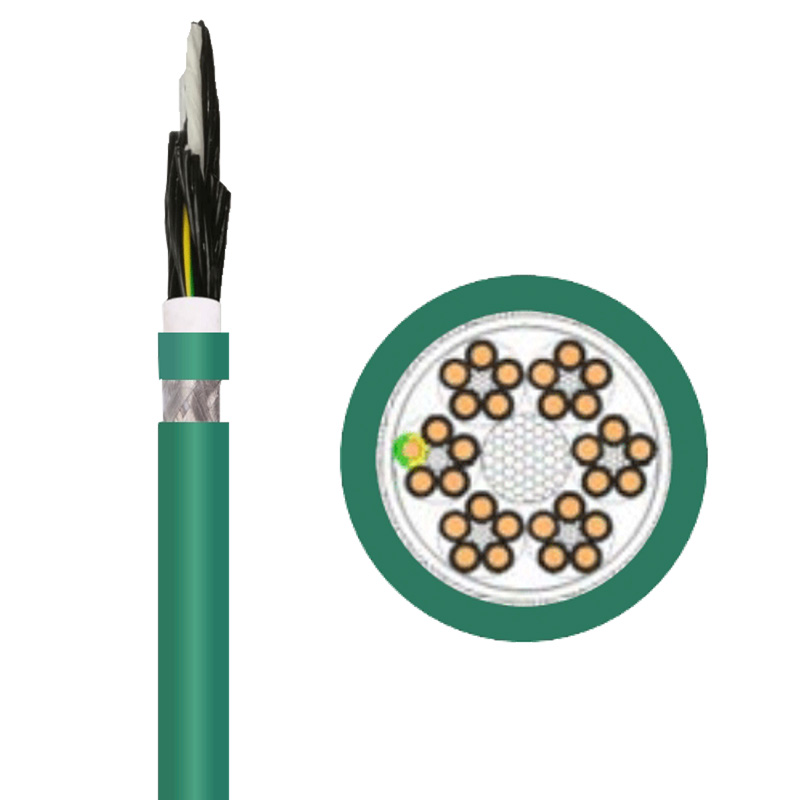

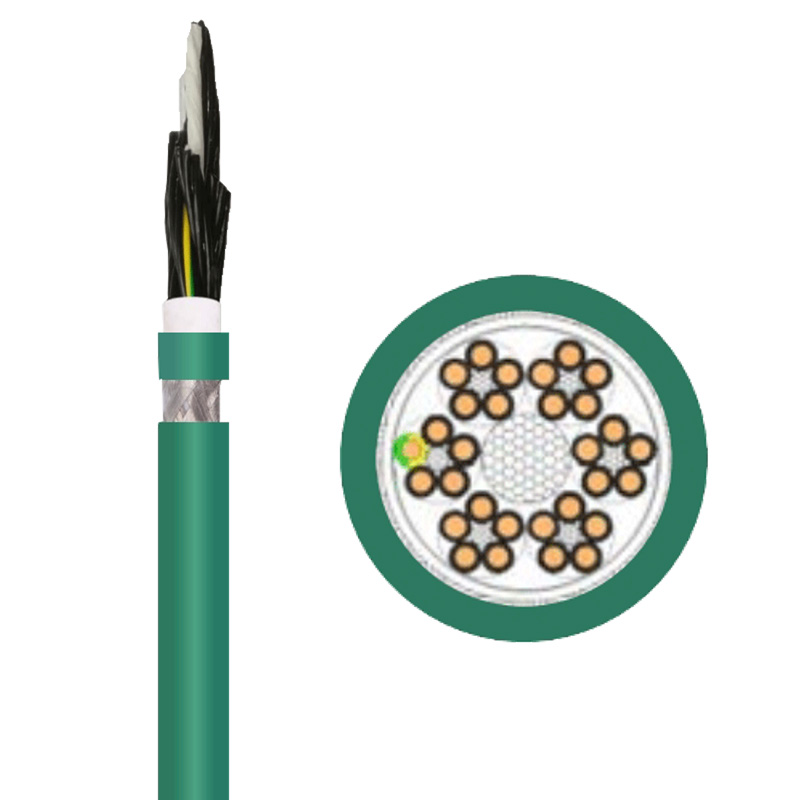

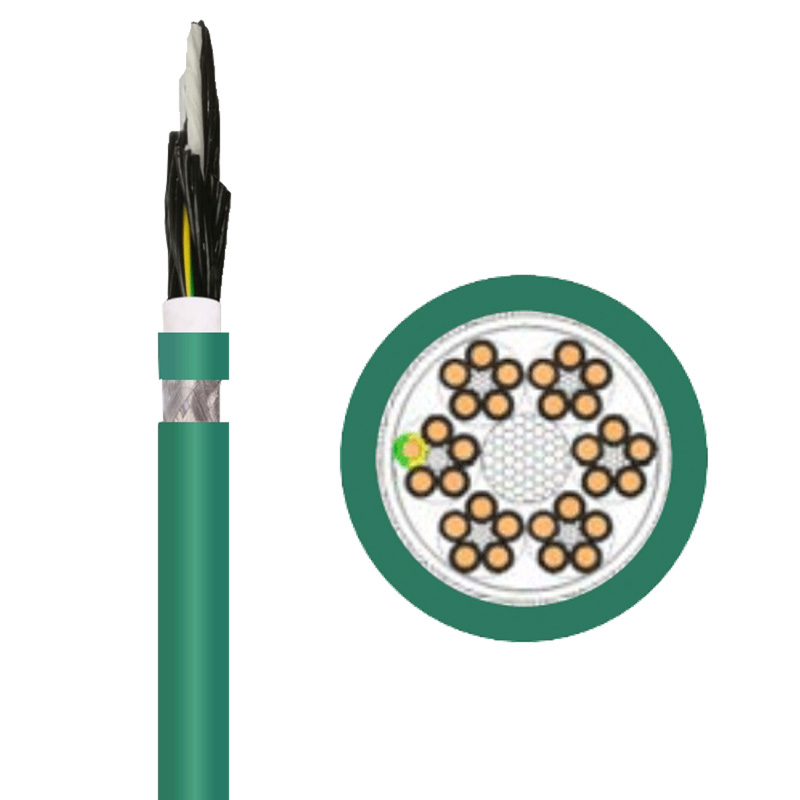

Cable Structure

Product Structure:

Complies with UL758 STYLE 2570

Conductor:

Fine bare copper stranded wire with high bend strength, conforming to DIN VDE 0295 Class 5 and IEC 60228 Class 5

Insulation:

High mechanical performance TPE polymer insulation

Core Wire Color:

Cross-sectional area < 0.5 mm²: Colored core wires for differentiation, colors conform to DIN 47100 standard

Cross-sectional area ≥ 0.5 mm²: Green-yellow ground wire with black core wire marked with white numbers

Stranding Method:

For core wire quantity < 12: Short pitch stranding in one layer

For core wire quantity ≥ 12: Grouped and twisted twice to enhance torsional strength

Inner Sheath: Modified PVC Polymer

Overall Shielding: High-strength tinned copper wire shielding, optical coverage ≥ 85%

Outer Jacket:

Modified high-strength PVC polymer

| Item | Product Code | Number of Cores and Cross-Sectional Area | Approximate Outer Diameter | Color | Product Number | MOQ |

| 1 | TY100.02.03.0025 | 3×0.25 | 5.50 | Dark Green | C-601 | |

| 2 | TY100.02.04.0025 | 4×0.25 | 6.00 | Dark Green | C-602 | |

| 3 | TY100.02.07.0025 | 7×0.25 | 7.20 | Dark Green | C-605 | |

| 4 | TY100.02.12.0025 | 12×0.25 | 10.00 | Dark Green | C-609 | ※ |

| 5 | TY100.02.18.0025 | 18×0.25 | 12.00 | Dark Green | C-612 | ※ |

| 6 | TY100.02.25.0025 | 25×0.25 | 14.00 | Dark Green | C-615 | ※ |

| 7 | TY100.02.02.0034 | 2×0.34 | 5.80 | Dark Green | C-619 | |

| 8 | TY100.02.05.0034 | 5×0.34 | 7.00 | Dark Green | C-622 | |

| 9 | TY100.02.07.0034 | 7×0.34 | 8.00 | Dark Green | C-624 | |

| 10 | TY100.02.12.0034 | 12×0.34 | 11.00 | Dark Green | C-628 | ※ |

| 11 | TY100.02.02.0050 | 2×0.5 | 6.50 | Dark Green | C-638 | |

| 12 | TY100.02.04.0050 | 4G0.5 | 7.50 | Dark Green | C-640 | |

| 13 | TY100.02.05.0050 | 5G0.5 | 8.00 | Dark Green | C-641 | |

| 14 | TY100.02.07.0050 | 7G0.5 | 9.00 | Dark Green | C-643 | |

| 15 | TY100.02.12.0050 | 12G0.5 | 12.50 | Dark Green | C-647 | ※ |

| 16 | TY100.02.18.0050 | 18G0.5 | 14.80 | Dark Green | C-650 | ※ |

| 17 | TY100.02.25.0050 | 25G0.5 | 16.80 | Dark Green | C-653 | ※ |

| 18 | TY100.02.03.0075 | 3G0.75 | 7.50 | Dark Green | C-658 | |

| 19 | TY100.02.04.0075 | 4G0.75 | 8.00 | Dark Green | C-659 | |

| 20 | TY100.02.05.0075 | 5G0.75 | 8.50 | Dark Green | C-660 | |

| 21 | TY100.02.07.0075 | 7G0.75 | 10.00 | Dark Green | C-662 | ※ |

| 22 | TY100.02.12.0075 | 12G0.75 | 13.80 | Dark Green | C-666 | ※ |

| 23 | TY100.02.18.0075 | 18G0.75 | 16.80 | Dark Green | C-669 | ※ |

| 24 | TY100.02.25.0075 | 25G0.75 | 18.80 | Dark Green | C-672 |

| Item | Product Code | Number of Cores and Cross-Sectional Area | Approximate Outer Diameter | Color | Product Number | MOQ |

| 25 | TY100.02.02.0100 | 2×1.0 | 7.50 | Dark Green | C-676 | |

| 26 | TY100.02.03.0100 | 3G1.0 | 7.80 | Dark Green | C-677 | |

| 27 | TY100.02.04.0100 | 4G1.0 | 8.50 | Dark Green | C-678 | |

| 28 | TY100.02.05.0100 | 5G1.0 | 9.20 | Dark Green | C-679 | |

| 29 | TY100.02.07.0100 | 7G1.0 | 10.80 | Dark Green | C-681 | |

| 30 | TY100.02.12.0100 | 12G1.0 | 14.80 | Dark Green | C-685 | ※ |

| 31 | TY100.02.18.0100 | 18G1.0 | 18.50 | Dark Green | C-688 | |

| 32 | TY100.02.25.0100 | 25G1.0 | 20.50 | Dark Green | C-691 | ※ |

| 33 | TY100.02.03.0150 | 3G1.5 | 8.50 | Dark Green | C-696 | |

| 34 | TY100.02.04.0150 | 4G1.5 | 9.20 | Dark Green | C-697 | |

| 35 | TY100.02.05.0150 | 5G1.5 | 10.00 | Dark Green | C-698 | ※ |

| 36 | TY100.02.07.0150 | 7G1.5 | 12.00 | Dark Green | C-700 | ※ |

| 37 | TY100.02.12.0150 | 12G1.5 | 16.80 | Dark Green | C-704 | ※ |

| 38 | TY100.02.18.0150 | 18G1.5 | 20.50 | Dark Green | C-707 | ※ |

| 39 | TY100.02.25.0150 | 25G1.5 | 23.00 | Dark Green | C-710 | ※ |

| 40 | TY100.02.36.0150 | 36G1.5 | 27.00 | Dark Green | C-712 | ※ |

| 41 | TY100.02.04.0250 | 4G2.5 | 11.00 | Dark Green | C-716 | ※ |

Notes

1.G = With yellow-green ground wire X = Without yellow-green ground wire 2.American Wire Gauge (AWG) sizes are approximate; actual cross-sectional area prevails 3.For wire with an outer diameter greater than 10mm, a minimum order of 10 meters is required for the specified ※ items, and delivery will be made as needed