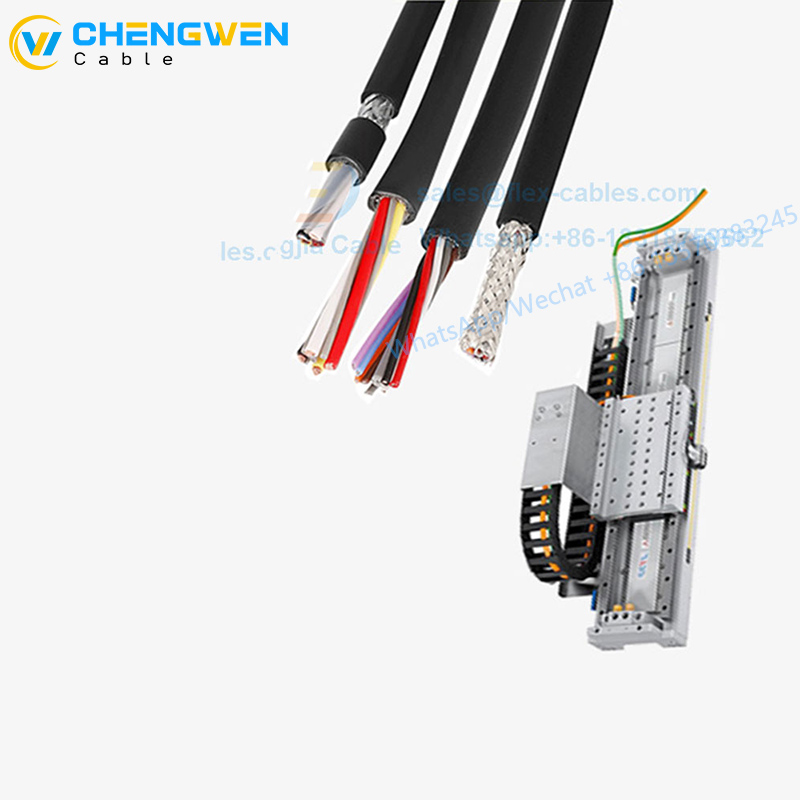

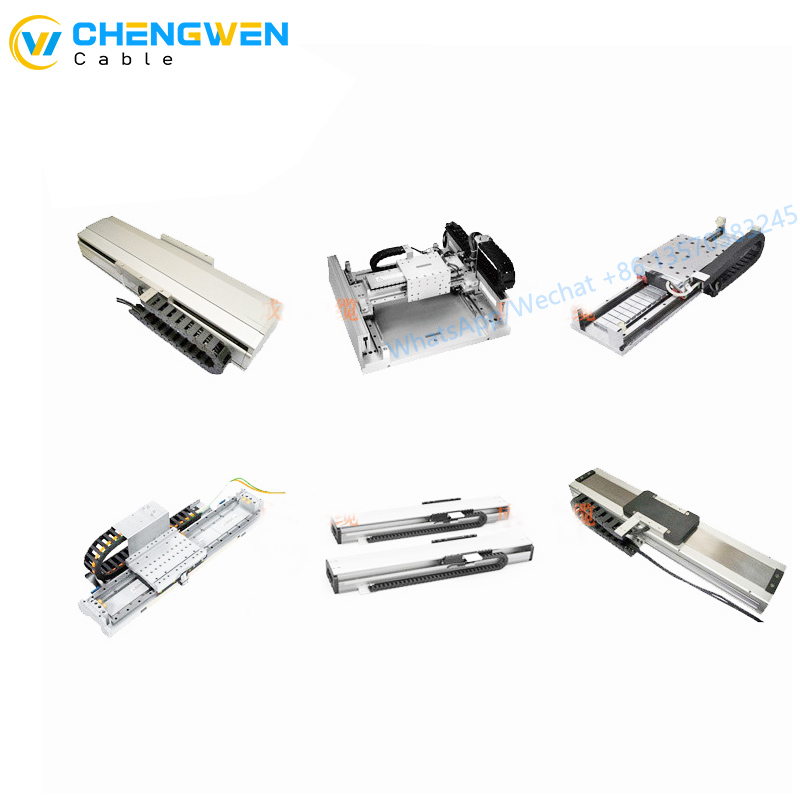

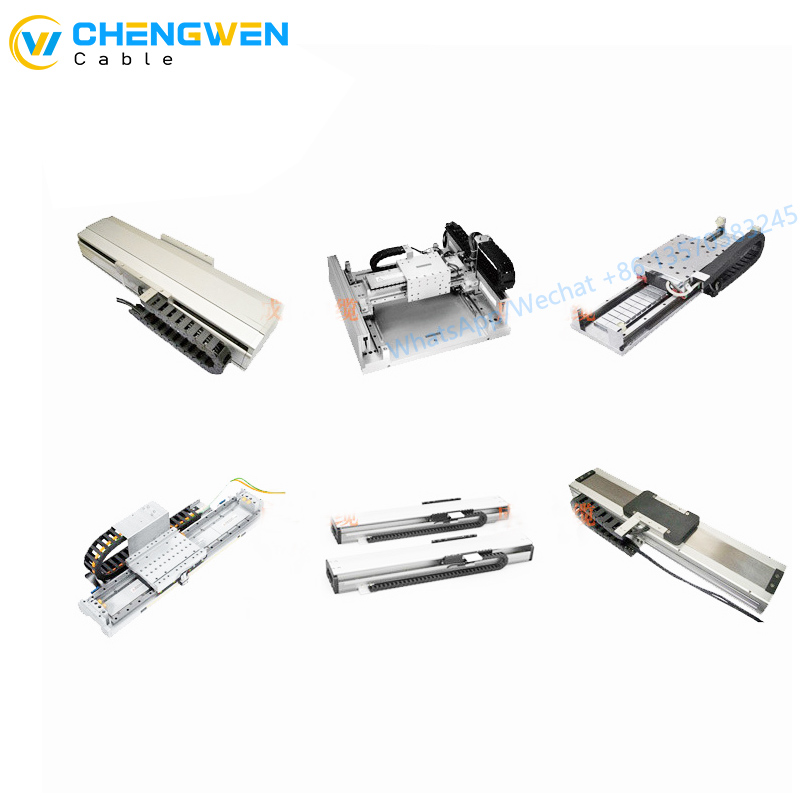

Application

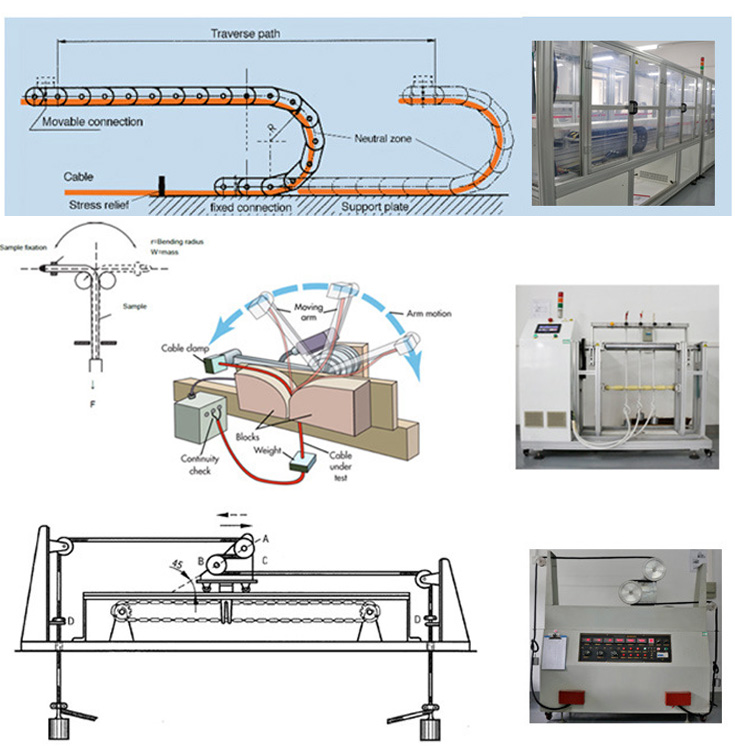

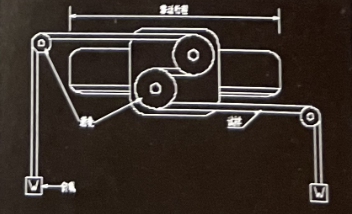

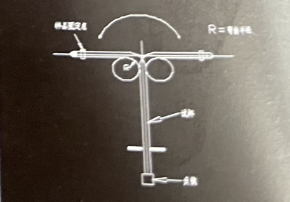

Especially suitable for long-term high-speed drag chain, bending, and high-strength applications in miniaturized linear motors. The cable for linear motors must meet the highest requirements in terms of mechanical, chemical, and thermal performance. They must withstand high-speed acceleration and deceleration, tensile and compressive stress, as well as cyclic bending exceeding 50 million times. They must also be resistant to high temperatures, metal shavings, oil, and other chemicals.

Technical data Linear Servo Motors Cable Linear Motor Wire

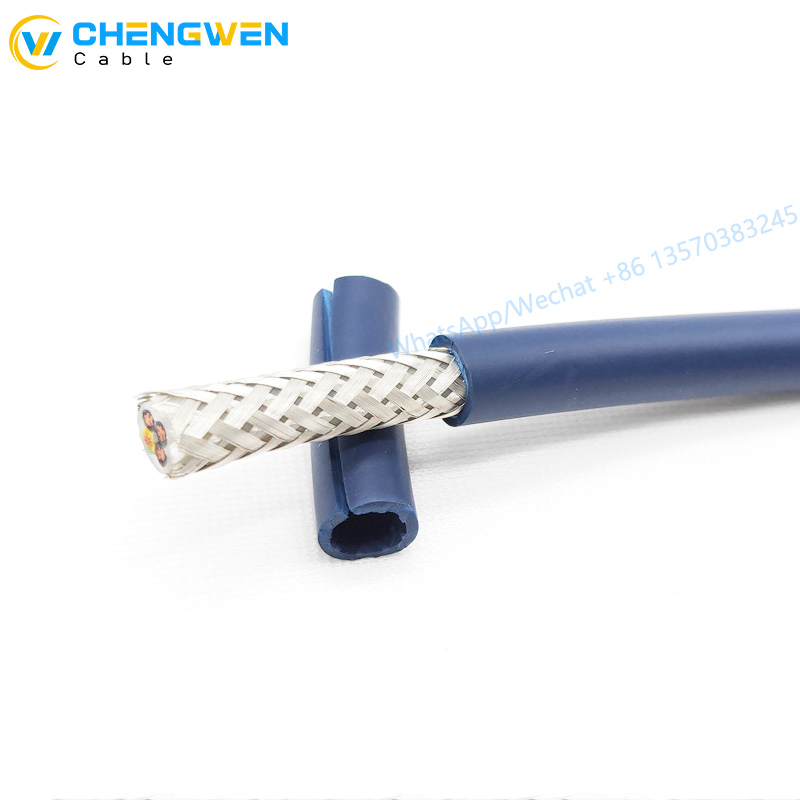

● The special Teflon insulation and special PUR sheath have ultra-high strength and bending/torsion performance

●omplies with TUV2 PfG 2577 Class V requirements.

●Temperature range: -20°C to +80°C for mobile installation -40°C to +90°C for fixed installation

●Nominal voltage 300/500V

●Test voltage 2000V

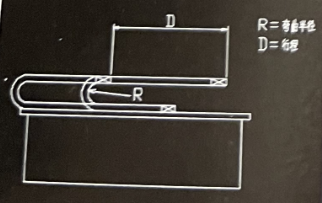

●Insulation resistance: Minimum 100 MOhm x km Minimum bending radius:6 x the cable diameter for mobile installation 4 x the cable diameter for fixed installation

●Complies with EU RoHS and Reach regulations.

●Oil resistance: Fully resistant to oil (in compliance with DIN EN50363-10-2 standard), Cass3.

● Black or color can be customized according to customer requirements.

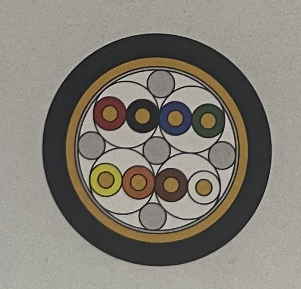

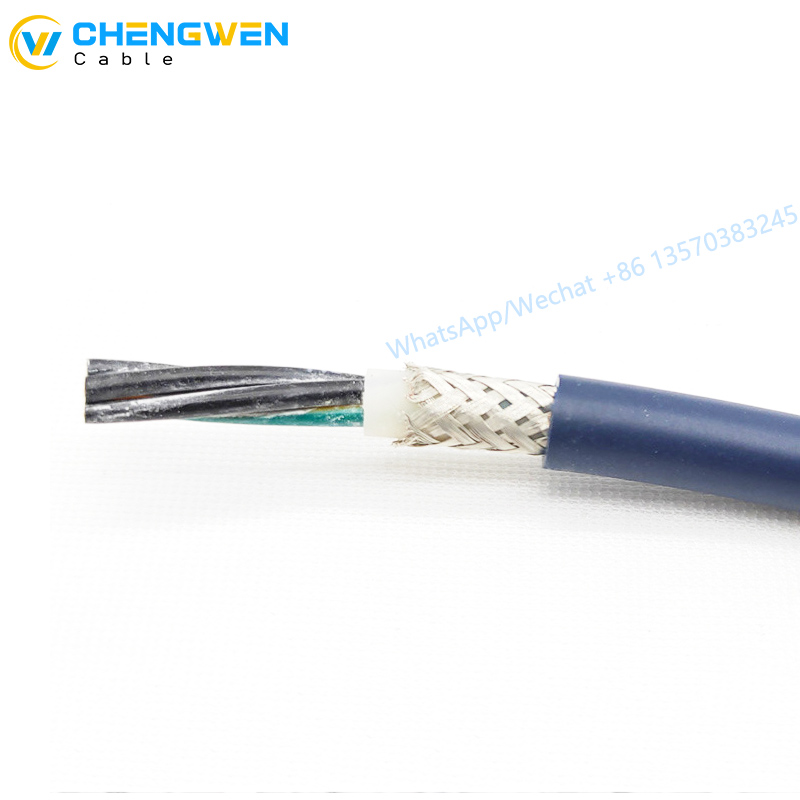

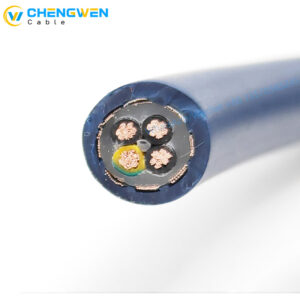

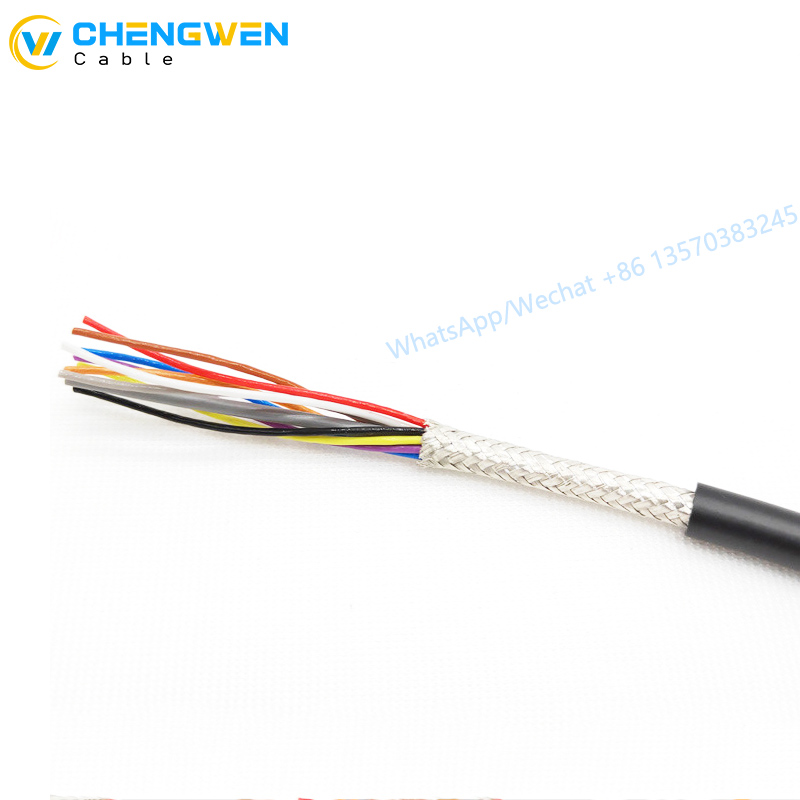

Cable Structure

●Bare copper conductor, ultra-fine copper wire Complies with DIN VDE 0295 Class 6 and IEC60228 Class 6

●Special fluororesin insulation

●Core wire color is color-coded

●Optimal pitch layer stranded core wire

●Improved tinned copper wire braided shield

● Minimum coverage of 95%

● Low-friction, PUR-based compound suitable for use in drag chains (in compliance with Part 10 of DIN 0281 standard).

| ULTRA HIGH SPEED LINEAR MOTOR ENCODER AND CONTROL CABLE ( 50 million times reliability tests for drag chain) | ||||

| No. | Product Code | Cores Number and cross-sectional area | Approximate outer diameter (mm) | Outer sheath color |

| (NO.Xm㎡) | ||||

| 1 | LM-FP5006.08.0020 | 4x2x0.2 | 6.4 | Black |

| 2 | LM-FP5002.08.0014 | 8×0.14 | 5.2 | Black |

| 3 | LM-FP5002.05.0014 | 5×0.14 | 4.2 | Black |