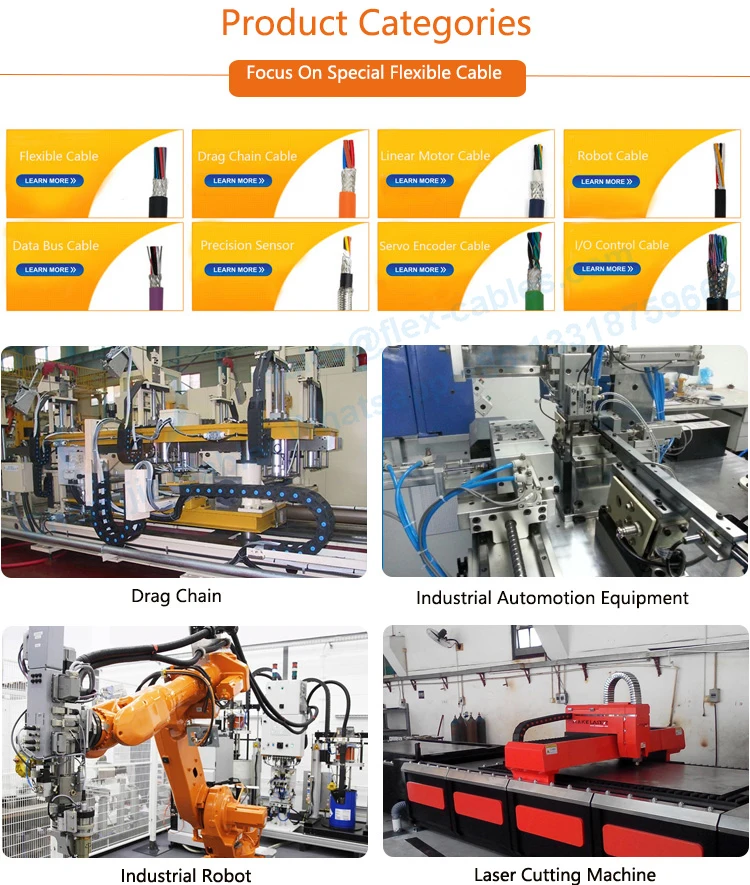

Application

● It adopts a wrapped structure, and the conductor is made of ultra-fine copper wire with a diameter of 0.08mm twisted into groups, providing a soft feel and good elasticity.

● It is suitable for extremely harsh industrial environments and places with corrosive coolant and lubricating oil, exhibiting excellent oil resistance and abrasion resistance.

● It has good resistance to microorganisms, hydrolysis, chemical corrosion, UV radiation, and low temperatures.

● It can be used indoors and outdoors in dry or humid conditions, especially suitable for industrial environments.

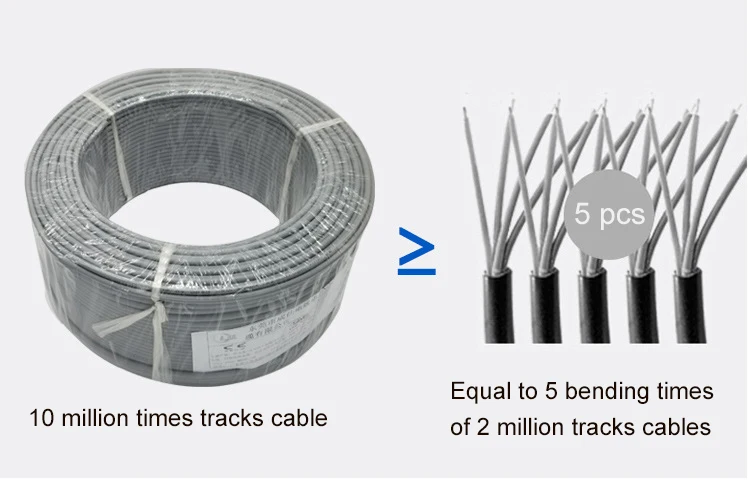

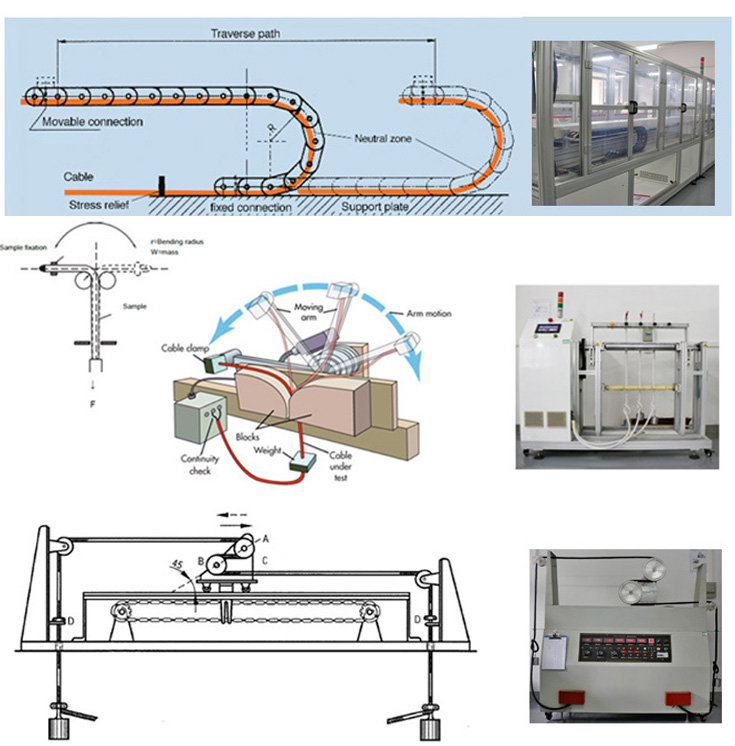

● Under normal usage conditions, it generally has a service life of more than 10 million cycles. Suitable for use in high-speed motion drag chains

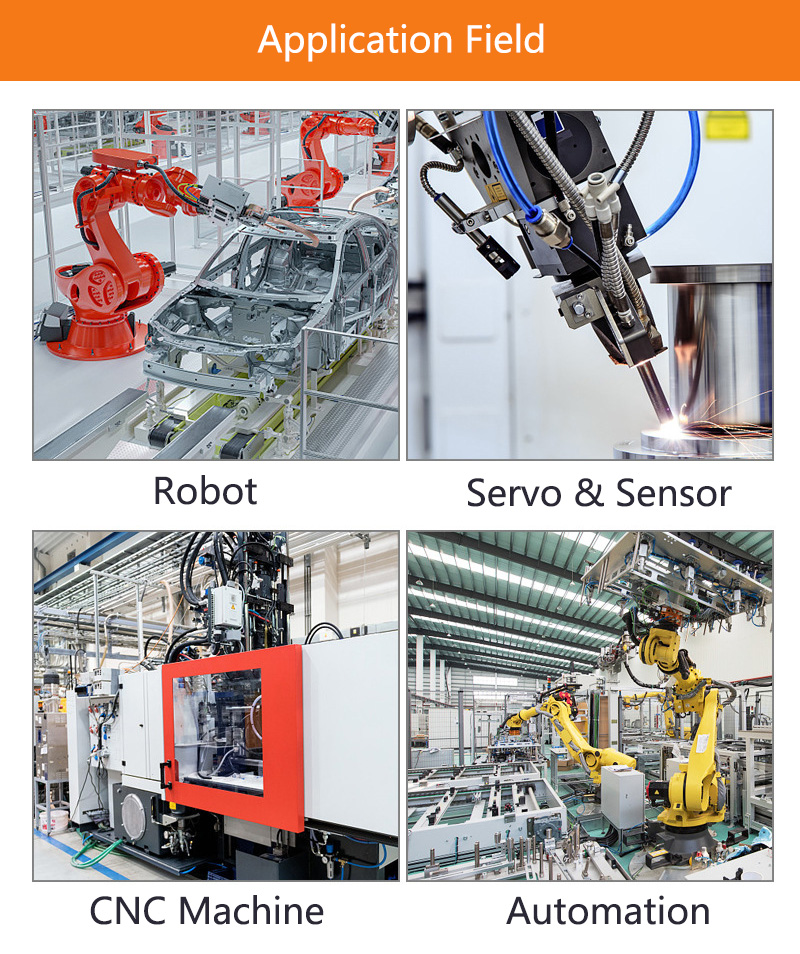

● Mainly used for power transmission in industrial automation, electromechanical equipment, machine tools, logistics equipment, and servo systems operating in harsh environments.

Technical data

●Specialized PUR sheath, highly flexible

●Temperature range: Mobile installation: -20°C to +80°C Fixed installation: -40°C to +90°C

●Maximum overhead/sliding speed: 5 m/s, 3 m/s

●Maximum acceleration: 50 m/s

● Test voltage: 2000V

● Insulation resistance:Minimum 20 MOhmxkm

● Minimum bending radius: Mobile installation: 6 x cable diameter Fixed installation: 4 x cable diameter

●Oil resistance: completely oil-resistant

● Compliant with EU RoHS and Reach regulations.

● Flame retardant, compliant with IEC 60332-1-2, CEI 20-35, FT1, VW-1.

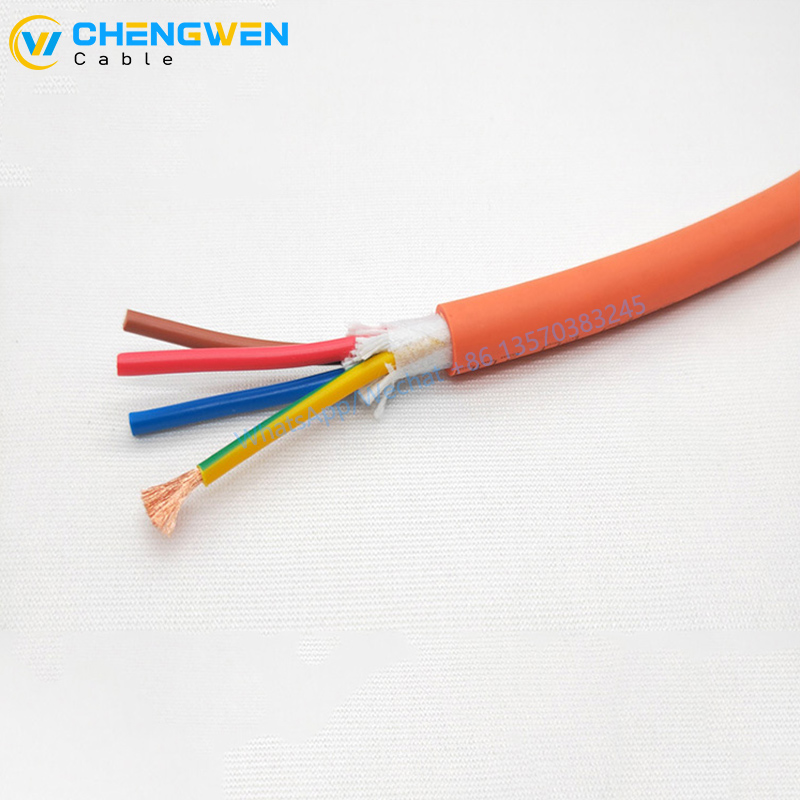

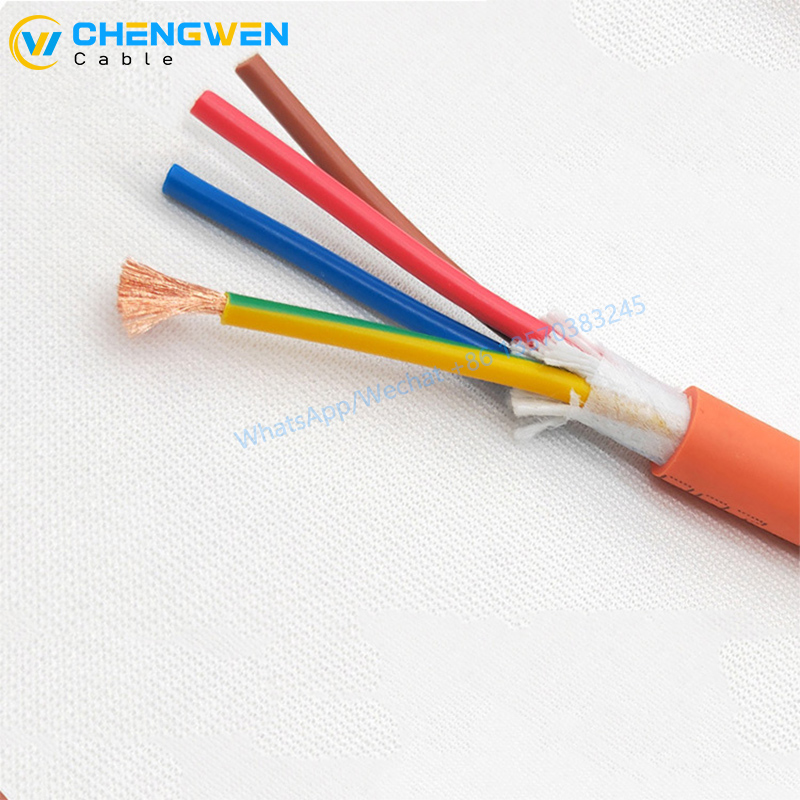

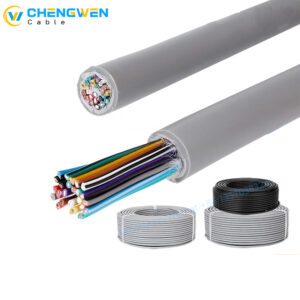

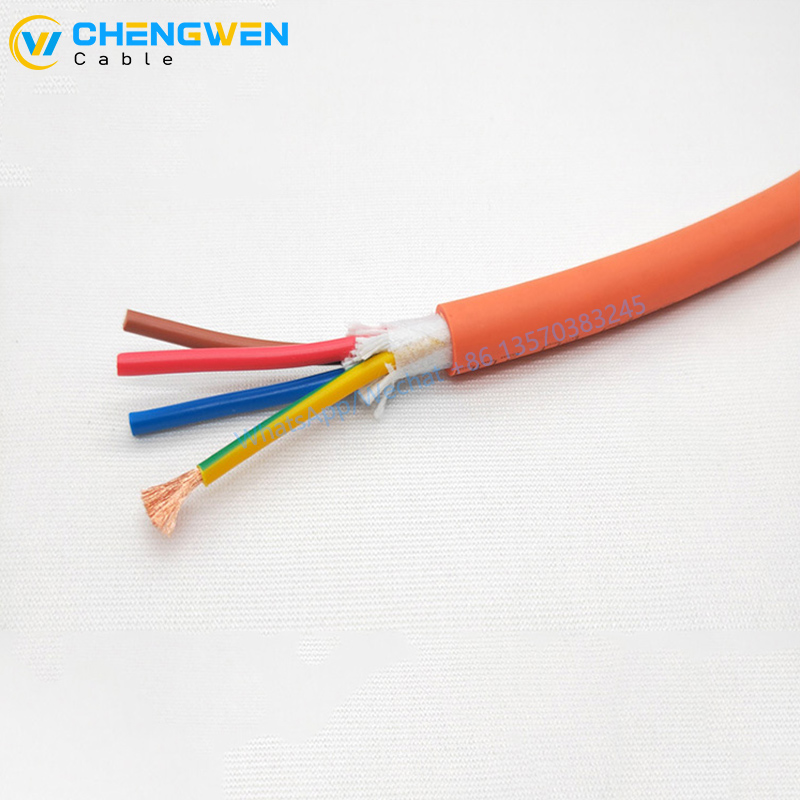

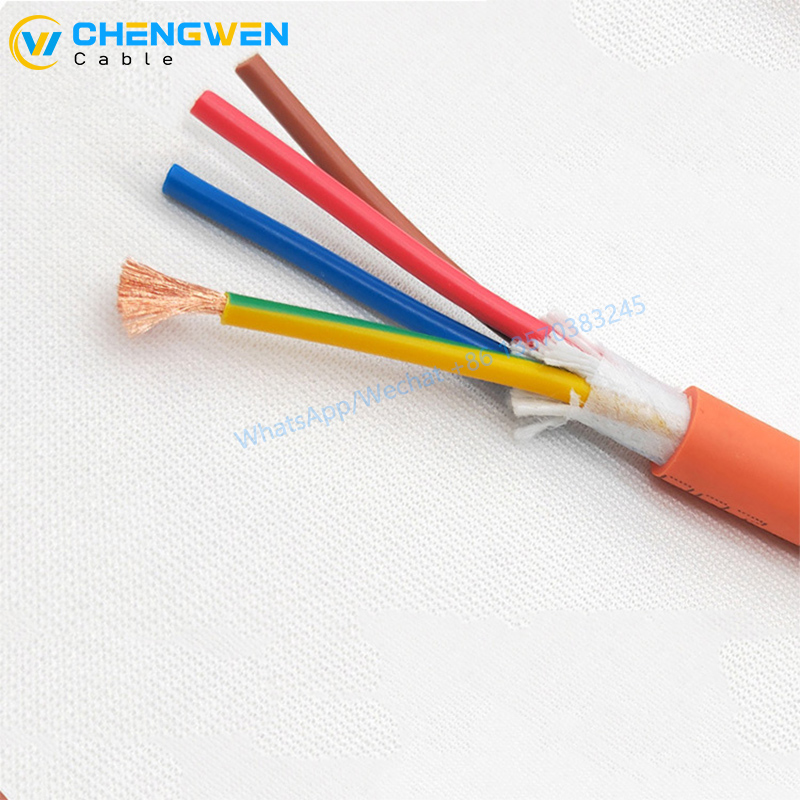

Cable Structure

● 0.08mm² Bare copper conductor, ultra-fine copper wire

● Compliant with DIN VDE 0295 Class 6 and IEC 60228 Class 6

●Special PVC insulation

●Color-coded cores

●Optimal pitch concentric stranded cores

●With yellow-green grounding wire (3 cores and above)

● Low friction, wear-resistant, low-temperature resistant, and oil-resistant PUR composite material.

● Orange, black, or color can be customized according to customer requirements.

| YP1007 ULTRA HIGH FLEXIBLE PUR DRAG CHAIN POWER CABLE ( 10 million times reliability tests for drag chain) | ||||

| No. | Product Code | Cores Number and cross-sectional area | Approximate outer diameter (mm) | Outer sheath color |

| (NO.Xm㎡) | ||||

| 1 | YP1007.02.0050 | 2×0.5 | 6.2 | Orange, Black |

| 2 | YP1007.03.0050 | 3G0.5 | 6.5 | Black |

| 3 | YP1007.04.0050 | 4G0.5 | 7.0 | Orange, Black |

| 4 | YP1007.02.0075 | 2×0.75 | 6.8 | Black |

| 5 | YP1007.03.0075 | 3G0.75 | 7.2 | Black |

| 6 | YP1007.04.0075 | 4G0.75 | 7.8 | Orange, Black |

| 7 | YP1007.02.0100 | 2×1.0 | 7.5 | Black |

| 8 | YP1007.03.0100 | 3G1.0 | 7.8 | Black |

| 9 | YP1007.04.0100 | 4G1.0 | 8.6 | Orange, Black |

| 10 | YP1007.03.0150 | 3G1.5 | 8.8 | Black |

| 11 | YP1007.04.0150 | 4G1.5 | 9.6 | Orange, Black |

| 12 | YP1007.03.0250 | 3G2.5 | 10.8 | Black |

| 13 | YP1007.04.0250 | 4G2.5 | 11.6 | Orange, Black |

| 14 | YP1007.04.0400 | 4G4.0 | 14.0 | Orange, Black |

| 15 | YP1007.04.0600 | 4G6.0 | 16.0 | Orange |

| 16 | YP1007.06.2022 | 4G0.5+2×0.3 | 7.5 | Orange |

| 17 | YP1007.06.1922 | 4G0.75+2×0.3 | 8.2 | Orange, Black |