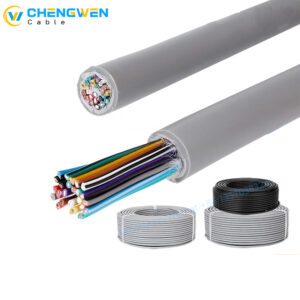

●The conductor is made up of ultra-fine copper wires (less than 0.1mm) twisted together in groups.

●The TRVV Towline Cable adopts a compacted structure, providing a relatively rigid feel compared to a wrapped structure.

●It has a strong load capacity, good rigidity, wear resistance, and moderate oil resistance.

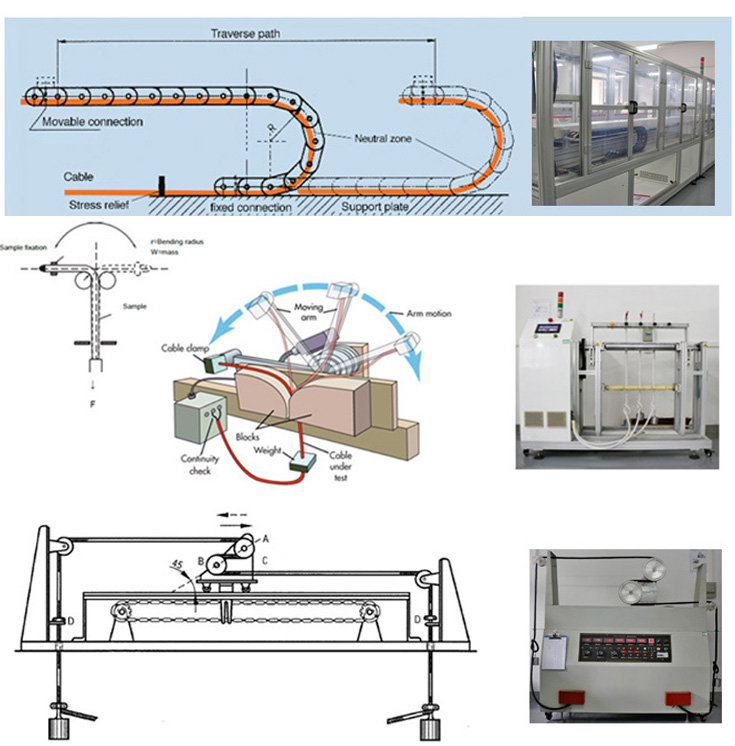

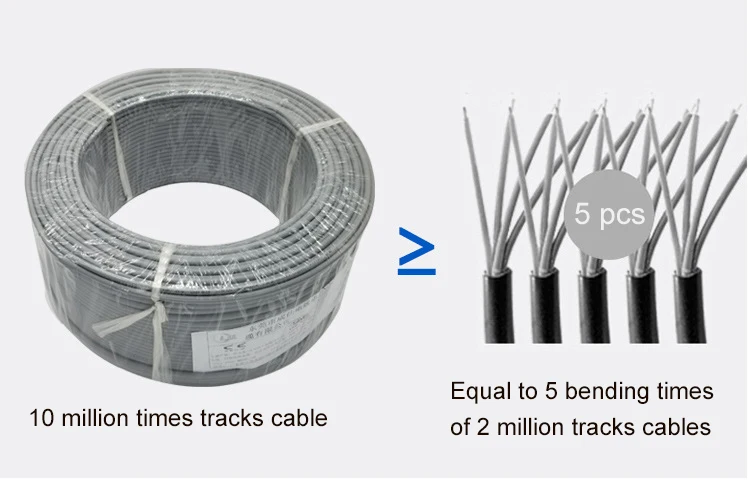

●Under specified installation and usage conditions, it can have a service life of over 10 million cycles.

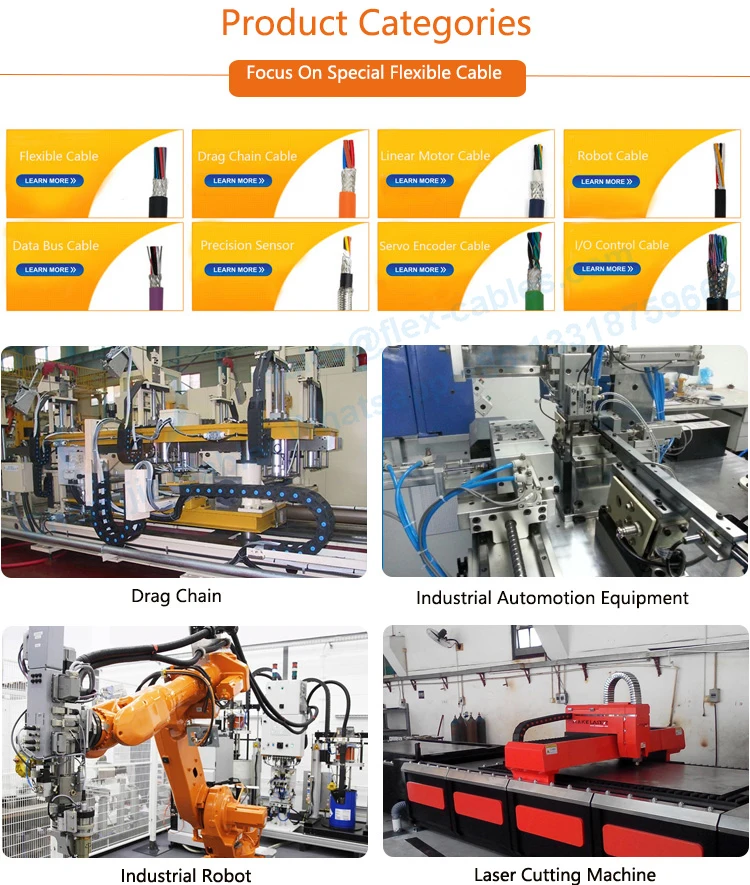

●It is highly suitable for high-speed bending motion in automation equipment such as large CNC machine tools and high-power laser cutting machines.

| L-YY1007 ULTRA HIGH FLEXIBLE DRAG CHAIN POWER CABLE (AMERICAN CORE WIRE) ( 10 million times reliability tests for drag chain) | ||||

| No. | Product Code | Cores Number and cross-sectional area | Approximate outer diameter (mm) | Outer sheath color |

| (NO.Xm㎡) | ||||

| 1 | L-YY1007.02.0050 | 2×0.5 | 6.2 | Orange, Black |

| 2 | L-YY1007.04.0050 | 4G0.5 | 7.0 | Orange, Black |

| 3 | L-YY1007.04.0075 | 4G0.75 | 7.8 | Orange, Black |

| 4 | L-YY1007.04.0150 | 4G1.5 | 9.6 | Orange, Black |

| 5 | L-YY1007.04.0250 | 4G2.5 | 11.6 | Orange, Black |

| 6 | MC-YY3007.04.0050 | 4G0.5 | 6.3 | Black |

| 7 | MC-YY3007.06.2024 | 4G0.5+2×0.2 | 6.3 | Black |

| 8 | MC-YY3007.04.0075 | 4G0.75 | 6.3 | Black |

Technical Parameter Of Ultra High Flexible Drag Chain Power TRVV Towline Cable

● Special PVC sheath, with ultra-high flexibility

● Temperature range Mobile installation: -5°C to +70°C Fixed installation: -15°C to +80°C

● Nominal voltage Uo/U: 300/500V

● Test voltage: 2000V

● Insulation resistance: Minimum 20 MOhmxkm

● Minimum bending radius: Mobile installation: 6 x cable diameter Fixed installation: 4 x cable diameter

●Compliant with EU RoHS and Reach regulations.

● Flame retardant, compliant with IEC 60332-1-2, CEI 20-35, FT1, VW-1.

Ultra High Flexible Drag Chain Power TRVV Towline Cable Structure