cable carrier power cables Parameter

| YP506 HIGH FLEXIBLE DRAG CHAIN DATA PUR CABLE ( 5 million times reliability tests for drag chain)) | ||||

| No. | Product Code | Cores Number and cross-sectional area | Approximate outer diameter (mm) | Outer sheath color |

| (NO.Xm㎡) | ||||

| 1 | YY507.02.0050 | 2×0.5 | 5.8 | Black/Orange |

| 2 | YY507.02.0051 | 3G0.5 | 6.2 | Black |

| 3 | YY507.02.0052 | 4G0.5 | 6.8 | Black/Orange |

| 4 | YY507.02.0053 | 2×0.75 | 6.2 | Black |

| 5 | YY507.03.0075 | 3G0.75 | 6.6 | Black |

| 6 | YY507.03.0076 | 4G0.75 | 7.2 | Black/Orange |

| 7 | YY507.03.0077 | 4G0.75+2×0.3 | 8.0 | Black/Orange |

| 8 | YY507.03.0078 | 2×1.0 | 6.6 | Black |

| 9 | YY507.03.0079 | 3G1.0 | 7.0 | Black |

| 10 | YY507.03.0080 | 4G1.0 | 7.8 | Black/Orange |

| 11 | YY507.03.0081 | 2×1.5 | 7.8 | Black |

| 12 | YY507.03.0082 | 3G1.5 | 8.2 | Black |

| 13 | YY507.03.0083 | 4G1.5 | 8.8 | Black/Orange |

| 14 | YY507.03.0084 | 3×1.5+1G1.0 | 8.8 | Black |

| 15 | YY507.03.0085 | 4G1.5+2×0.5 | 10.5 | Black/Orange |

| 16 | YY507.03.0086 | 2×2.5 | 9.2 | Black |

| 17 | YY507.03.0087 | 3G2.5 | 9.8 | Black |

| 18 | YY507.03.0088 | 4G2.5 | 11.0 | Black/Orange |

| 19 | YY507.03.0089 | 3×2.5+1G1.5 | 11.0 | Black/Orange |

| 20 | YY507.02.0400 | 2×4.0 | 11.2 | Black |

| 21 | YY507.03.0400 | 3G4.0 | 11.8 | Black |

| 22 | YY507.04.0400 | 4G4.0 | 13.0 | Black/Orange |

| 23 | YY507.04.0600 | 4G6.0 | 14.5 | Black/Orange |

| 24 | YY507.04.1000 | 4G10.0 | 19.5 | Black/Orange |

| 25 | YY507.04.1600 | 4G16.0 | 23.0 | Black/Orange |

cable carrier power cables Technical data

●Special PVC sheath with high flexibility

Temperature range: Mobile installation -5°C to +70°C Fixed installation -15°C to +80°C

●Nominal voltage Uo/U 300/500V

●Test voltage 2000V

●Insulation resistance: Minimum 20 MOhmxkm

●Minimum bending radius: Mobile installation 7.5x cable diameter Fixed installation 6x cable diameter

●Compliant with EU RoHS and Reach regulations

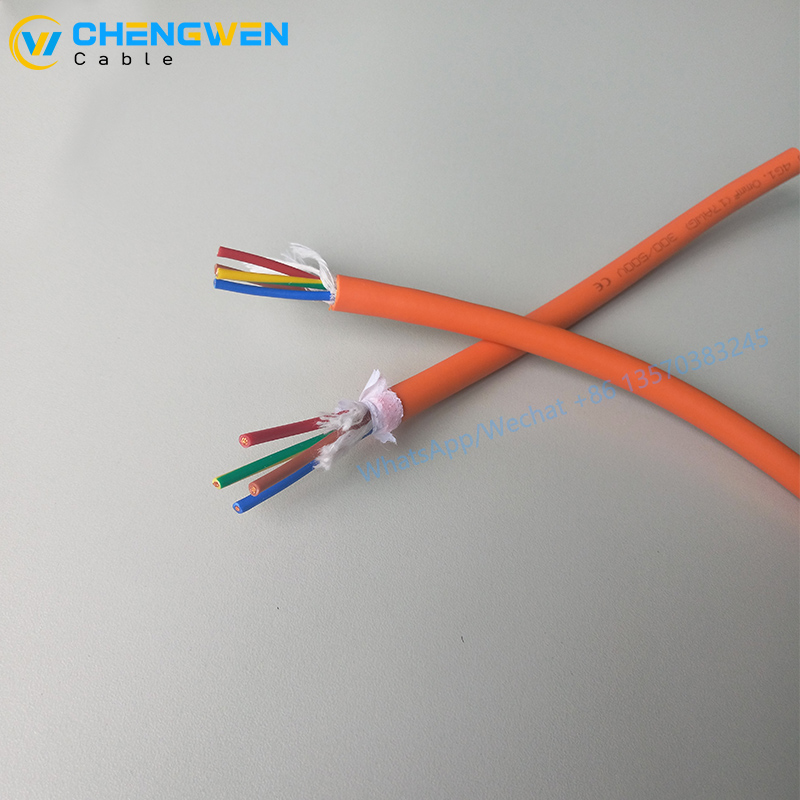

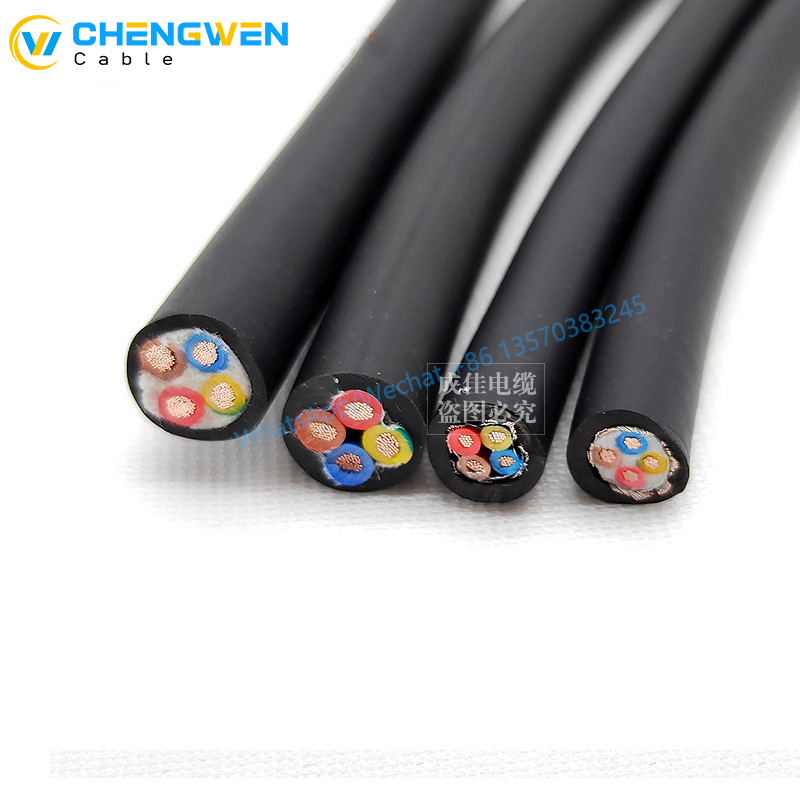

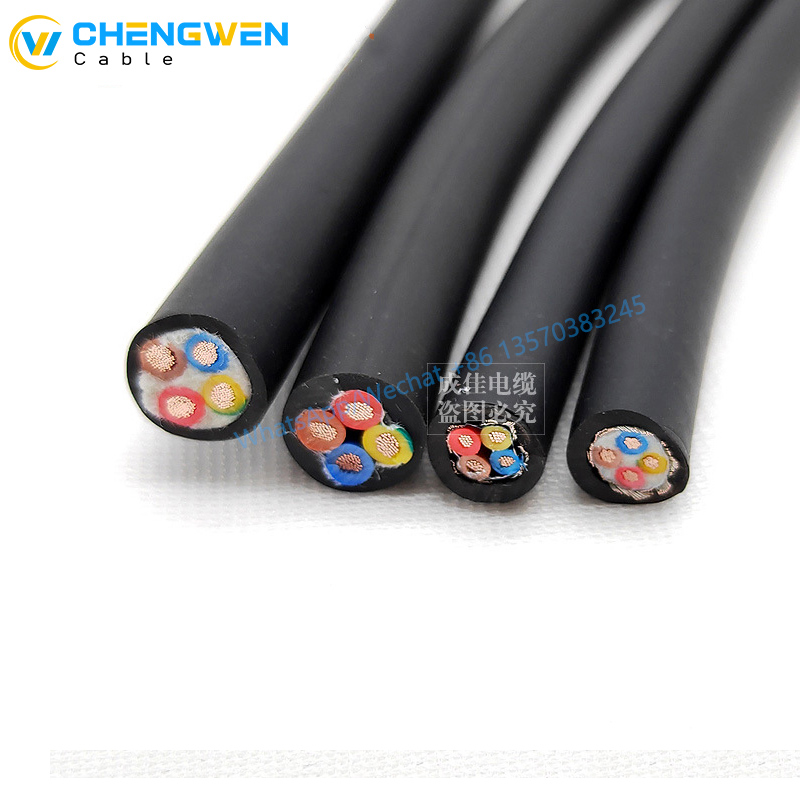

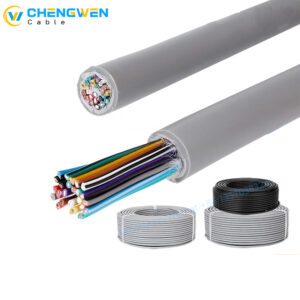

cable carrier power cables Structure:

● Bare copper conductor, fine copper wire Compliant with DIN VDE 0295 Class 6 and IEC 60228 Class 6

● Special PVC insulation

● Color-coded core identification

● Optimal lay length for stranded cores

● With yellow-green grounding wire (3 cores and above)

● Special PVC outer sheath

● Black color (RAL 9005) matte finish

| High Flexibility 5 Million Times Drag Chain Cable Test Standards | ||

| Drag Chain Bending Test Test Method: Take a 2-meter finished cable, with a bending radius of 6 times the outer diameter of the cable, a moving stroke of 900 mm, and reciprocating movement at a speed of 90 times/minute. |

Two-Wheel Winding Test Test Method: Take a 5-meter finished cable, according to the specified pulley diameter and weight of the weights. The pulley moves at a speed of 0.33 m/sec, and the moving distance is more than 1.0 meter under reciprocating conditions |

90-Degree Bend Test Test Method: Take a 2-meter finished cable, with a bending radius of 2.5 times the outer diameter of the cable, according to the standard specified weight of the weights, bending at a speed of 40 times/minute |

| Judgment Criteria: 1. The number of reciprocations exceeds 5,000,000 times without open circuit or short circuit. 2. The sheath is not broken | Judgment Criteria: 1. The number of reciprocations exceeds 200,000 times without open circuit or short circuit. 2. The sheath is not broken | Judgment Criteria: 1. The number of reciprocations exceeds 100,000 times without open circuit or short circuit. 2. The sheath is not broken |