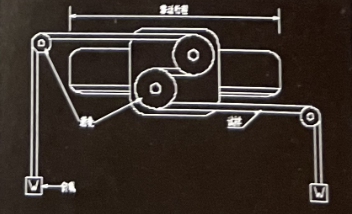

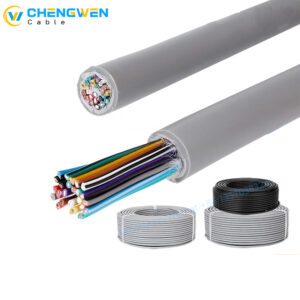

Especially suitable for small-scale, long-term, high-speed drag chain, bending, and high-intensity applications like linear

motors, the 20 Million Times Linear Motor Power Cable for linear motors must meet the highest requirements in terms of

mechanical, chemical, and thermal performance. They must withstand high-speed acceleration and deceleration, tension,

compression stress, as well asmore than twenty million cycles of periodic bending. Additionally, they must be resistant to

high temperatures, metal shaving splashes, oil, and other chemicals.

Technical data Linear Motor Power Cable

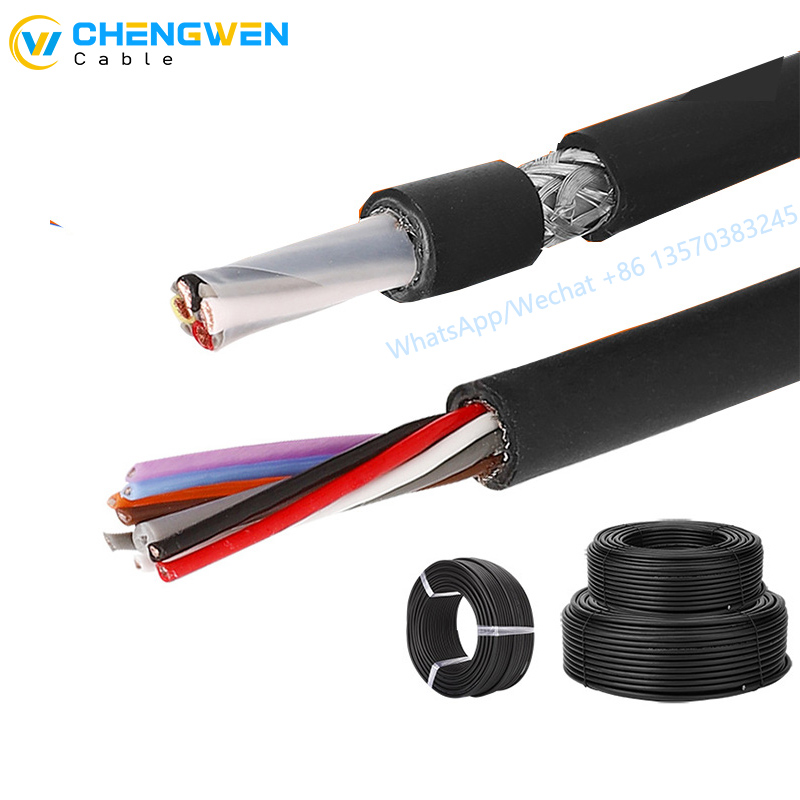

TPE-E insulation, special PUR outer sheath

Has ultra-high strength and bending properties

Conforms to TUV 2 PfG 257 7ClassII requirements

Temperature range: Mobile installation -20°C to +80°C

Fixed installation -40°C to +90°C

Nominal voltage Uo/U300/500V

Test voltage 2000V

Insulation resistance:

Minimum 100MOhmxkm0

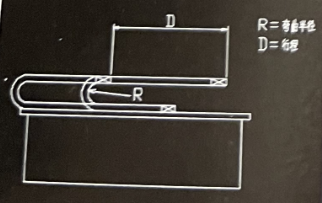

Minimum bending radius:

Mobile installation 6X cable diameter

Fixed installation 4X cable diameter

Meet EU ROHS, Reach regulations

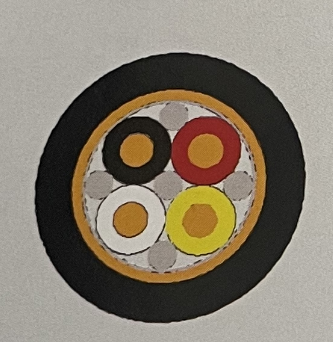

Bare copper conductor, ultra-fine copper wire

Conforms to DIN VDE 0295 category 6 and IEC 60228 category 6

TPE-E insulation

The color of the core wire is colored

The cores are layered and stranded at an optimal pitch

Special material inner sheath

Improved Tinned Copper Wire Braid Shield

Minimum coverage 90%

Special PUR outer sheath

black (RAL 9005) matte

Linear Motor Power Cable Parameter |

||||

| No. | Product Code | Cores Number and cross-sectional area | Approximate outer diameter (mm) | Outer sheath color |

| (NO.Xm㎡) | ||||

| 1 | LM-TP2002.04.0050 | 4X0.5 | 5.5 | Black |

| 2 | LM-TP2002.04.0075 | 4X0.75 | 6.5 | Black |

| 3 | LM-TP2002.04.0100 | 4X1 | 7.5 | Black |

| 4 | LM-TP2002.04.0150 | 4X1.5 | 8.5 | Black |

| 5 | LM-TP2002.04.0250 | 4X2.5 | 9.5 | Black |

Linear Motor Power Cable Parameter |

||||

| No. | Product Code | Cores Number and cross-sectional area | Approximate outer diameter (mm) | Outer sheath color |

| (NO.Xm㎡) | ||||

| 6 | LM-YP2002.04.0075 | 4G 0.75 | 7.3 | Black |