Unshielded YY02 Flexible PVC Control Cable are used for electrical connection in industrial automation, complete sets

of electromechanical equipment, machine tools and other mechanical equipment, logistics transmission systems, production

lines and other control systems. They are especially suitable for fixed installations in industrial environments, dry or humid

indoors, and can also be used for non- Mobile installation with continuous reciprocating motion without forced traction. The

black outer sheath has anti-ultraviolet properties and can be installed outdoors in the open, but direct burial is not allowed.

The cable has good flexibility. The sheath is made of oil-resistant PVC, so that the cable has good oil resistance.

YY02 Flexible PVC Control Cable Technical Parameter

|

Standard

|

Comply with UL20276 standard, thin wire diameter design

|

|||

|

Conductor

|

adopts high-quality tinned copper stranded copper wire

|

|||

|

Insulation material

|

Modified PVC

|

|||

|

Core structure

|

Small pitch single stranding

|

|||

|

Core recognition

|

Below 0.5m㎡ is marked with colored core wires; 0.5m㎡ above, a yellow-green ground wire + black core wire with white numbers

|

|||

|

Outer sheath

|

Modified PVC mate

|

|||

|

Color

|

black (other colors can be customized)

|

|||

|

Bending radius

|

Move in drag chain is more than 7.5 x d,

non-tow chain is moved more than 6 x d,

fixed laying is more than 5 x d

|

|||

|

Movement speed:

|

fixed or low-speed movement, less than 0.3 m/s

|

|||

|

Travel distance

|

Fixedly laid, less than 30 meters, and the signal is attenuated if it is too long.

|

|||

|

Nominal voltage

|

Uo/U 300/300 V

|

|||

|

Test voltage

|

1500 V

|

|||

|

Application:

|

It is especially suitable for fixed installation of mechanical equipment and machine tools or occasional mobile applications. The flexible cable uses specially modified insulation and sheath materials, has abrasion resistance and medium resistance, and has more than one million periodic bends, and always maintains stability.

|

|||

YY02 Flexible PVC Control Cable Structure

1. Tinned copper (less than 0.5mm2) or bare copper (0.5mm2 and above) conductor thin copper wire, in line with DIN VDE0295 category 6 and IEC 60228 category 6

2. Special PVC insulation

3. Color core wire identification (less than 0.5mm2)

4. Black core wire with continuous white digital code (0.5mm2 and above) The yellow-green ground wire is on the outer layer (3 cores and above)

5. The wire core is stranded in layers with the best pitch

6. Improved tinned copper wire braided shield

7. The minimum comprehensive shielding rate is 80%

8. Special PVC outer sheath

9. Black (RAL 9005) matte

|

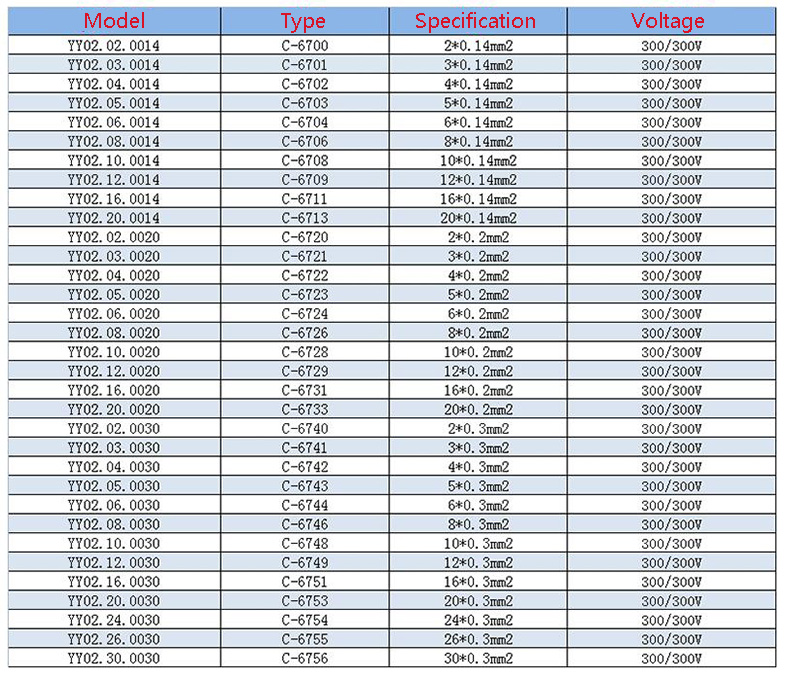

No.

|

Product Code

|

Cores Number and cross-sectional area

(NO.Xm㎡)

|

Approximate outer diameter (mm)

|

Outer sheath color

|

20℃ Conductor DC resistance

Ω/km

|

|

1

|

YY02.02.0014

|

2×0.14

|

4.0

|

Black

|

150

|

|

2

|

YY02.03.0014

|

3×0.14

|

4.2

|

Black

|

150

|

|

3

|

YY02.04.0014

|

4×0.14

|

4.5

|

Black

|

150

|

|

4

|

YY02.05.0014

|

5×0.14

|

4.8

|

Black

|

150

|

|

5

|

YY02.06.0014

|

6×0.14

|

5.2

|

Black

|

150

|

|

6

|

YY02.08.0014

|

8×0.14

|

5.5

|

Black

|

150

|

|

7

|

YY02.10.0014

|

10×0.14

|

6.4

|

Black

|

150

|

|

8

|

YY02.12.0014

|

12×0.14

|

6.5

|

Black

|

150

|

|

9

|

YY02.16.0014

|

16×0.14

|

7.2

|

Black

|

150

|

|

10

|

YY02.20.0014

|

20×0.14

|

7.8

|

Black

|

150

|

|

11

|

YY02.02.0020

|

2×0.2

|

4.4

|

Black

|

95

|

|

12

|

YY02.03.0020

|

3×0.2

|

4.6

|

Black

|

95

|

|

13

|

YY02.04.0020

|

4×0.2

|

4.9

|

Black

|

95

|

|

14

|

5YY02.05.0020

|

5×0.2

|

5.2

|

Black

|

95

|

|

15

|

YY02.06.0020

|

6×0.2

|

5.6

|

Black

|

95

|

|

16

|

YY02.08.0020

|

8×0.2

|

6.0

|

Black

|

95

|

|

17

|

YY02.10.0020

|

10×0.2

|

6.8

|

Black

|

95

|

|

18

|

YY02.12.0020

|

12×0.2

|

7.0

|

Black

|

95

|

|

19

|

YY02.16.0020

|

16×0.2

|

7.6

|

Black

|

95

|

|

20

|

YY02.20.0020

|

20×0.2

|

8.5

|

Black

|

95

|

|

21

|

YY02.02.0030

|

2×0.3

|

4.6

|

Black

|

71.2

|

|

22

|

YY02.03.0030

|

x0.3

|

4.8

|

Black

|

71.2

|

|

23

|

YY02.04.0030

|

4×0.3

|

5.1

|

Black

|

71.2

|

|

24

|

YY02.05.0030

|

5×0.3

|

5.5

|

Black

|

71.2

|

|

25

|

YY02.06.0030

|

6×0.3

|

6.0

|

Black

|

71.2

|

|

26

|

YY02.08.0030

|

8×0.3

|

6.4

|

Black

|

71.2

|

|

27

|

YY02.10.0030

|

10×0.3

|

7.2

|

Black

|

71.2

|

|

28

|

YY02.12.0030

|

12×0.3

|

7.5

|

Black

|

71.2

|

|

29

|

YY02.16.0030

|

16×0.3

|

8.4

|

Black

|

71.2

|

|

30

|

YY02.20.0030

|

20×0.3

|

9.0

|

Black

|

71.2

|

|

MOQ 1 meter, If you need to order PUR outer sheath, MOQ 400 meters

|

|||||

FAQ