Flexible cables, with their exceptional bendability, wear resistance, and anti-interference capabilities, have become indispensable connecting components in modern industrial automation and precision equipment.

They demonstrate advantages unmatched by traditional cables in scenarios requiring frequent movement, complex wiring, and high reliability.

In the field of industrial robots

Flexible wire are the key to ensuring the flexible movement of robotic arms. The welding, assembly, and spraying robots on the production line require continuous multidimensional activities, with extremely high requirements for the bending life and torsional resistance of the connecting cables.

High quality flexible cord can withstand millions of reciprocating movements, ensuring stable signal and power transmission, greatly improving the efficiency and reliability of automated production.

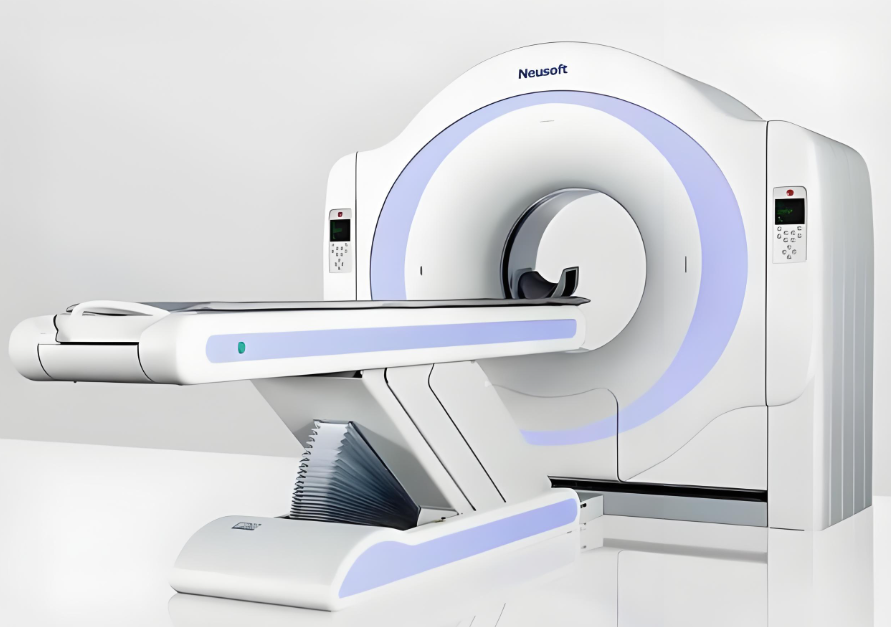

In the medical equipment industry

The application of flexible cables is equally crucial. Whether it is the complex slip ring transmission in large imaging equipment such as CT machines and DR systems, or the internal connections in surgical robots’ fine robotic arms, 유연한 와이어 need to have excellent flexibility, biocompatibility, and resistance to disinfectant corrosion. This ensures the long-term stable operation of medical equipment in harsh environments and patient safety.

In the field of new energy

Especially for photovoltaic and wind power generation systems, Flex cable are widely used.

Solar panels need to be adjusted according to the angle of the sun, and the blades and nacelle of wind turbines also undergo continuous yaw and pitch movements.

Flexible cables suitable for outdoor environments have excellent weather resistance, UV resistance, and wide temperature range working characteristics, which can effectively cope with the challenges of natural environments and ensure the sustainable power transmission of clean energy systems.

In the field of CNC equipment

Flex wire play a core role in semiconductor manufacturing, precision machine tools, logistics sorting systems, and even stage lighting equipment.

It solves the problems of cable winding, wear and signal attenuation during high-speed and high-frequency movement of equipment, providing a solid foundation for precision control and efficient operation of various high-end equipment.