Données techniques Câble de connexion encodeur linéaire

● Isolation TPE-E, gaine extérieure spéciale en PUR à ultra haute résistance et résistance à la flexion

●Répond aux exigences TUV2 PfG

●Plage de température : -20°C à +80°C pour une installation mobile -40°C à +90°C pour une installation fixe

●Tension nominale 300/500 V

●Tension d'essai 2000V

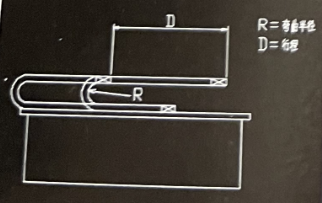

●Résistance d'isolement : Minimum 100 MOhm x km Rayon de courbure minimum : 6 x le diamètre du câble pour une installation mobile 4 x le diamètre du câble pour une installation fixe

● Conforme aux réglementations européennes RoHS et Reach.

●Résistance à l'huile : Totalement résistante à l'huile (conforme à la norme DIN EN50363-10-2), Cass3.

● Le noir ou la couleur peuvent être personnalisés selon les exigences du client.

● Conducteur en cuivre nu, fil de cuivre ultra-fin

●Conforme aux normes DIN VDE 0295 Classe 6 et CEI

● Isolation TPE-E

● Fils centraux de différentes couleurs

● Superposition optimale des fils centraux

● Gaine intérieure en matériau spécial

● Blindage tressé en fil de cuivre étamé amélioré

● Couverture minimale de 95 %

● Composé à base de PUR à faible friction adapté à une utilisation dans les chaînes porte-câbles (conforme à la partie 10 de la norme DIN 0281).

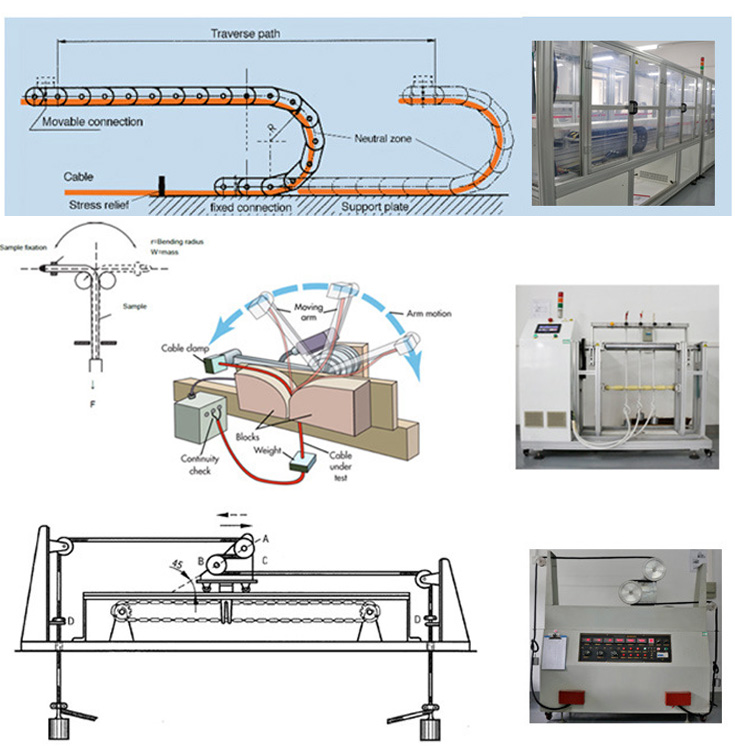

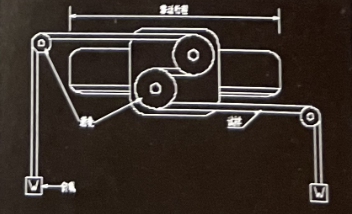

| CODEUR LINÉAIRE ULTRA HAUTE VITESSE ET CÂBLE DE COMMANDE (20 millions de tests de fiabilité pour la chaîne porte-câbles) | ||||

| Non. | Code produit | Nombre de noyaux et section transversale | Diamètre extérieur approximatif (mm) | Couleur de la gaine extérieure |

| (NO.Xm㎡) | ||||

| 1 | LM-YP2006.08.0020 | 4x2x0,2 | 6 | Noir |

| 2 | LM-YP2006.08.0014 | 4x2x0,14 | 5.5 | Noir |

| 3 | LM-YP2002.08.0014 | 8×0,14 | 5.2 | Noir |

| 4 | LM-YP2002.05.0014 | 5×0,14 | 4.2 | Noir |

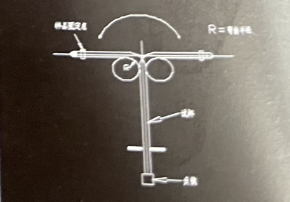

Selon les caractéristiques de fonctionnement à grande vitesse, d'accélération élevée, de haute précision et de petit rayon de courbure des moteurs linéaires, le conducteur est conçu à l'aide d'un fil de cuivre ultra-fin avec une torsion précise. Il est isolé en ETFE et possède une gaine extérieure en PUR de haute qualité, améliorant considérablement la résistance à la fatigue du câble. Dans des conditions normales d'utilisation, la durée de vie en flexion peut dépasser 20 millions de cycles. Il est totalement résistant à l’huile et peut supporter de basses températures