In the field of modern industrial automation, drag chain cable serve as critical components connecting moving parts and power sources, directly impacting the operational efficiency and stability of equipment.

Selecting an appropriate drag chain cable can not only effectively extend the service life of the equipment but also reduce maintenance costs and production downtime.

The role and importance of drag chain cables

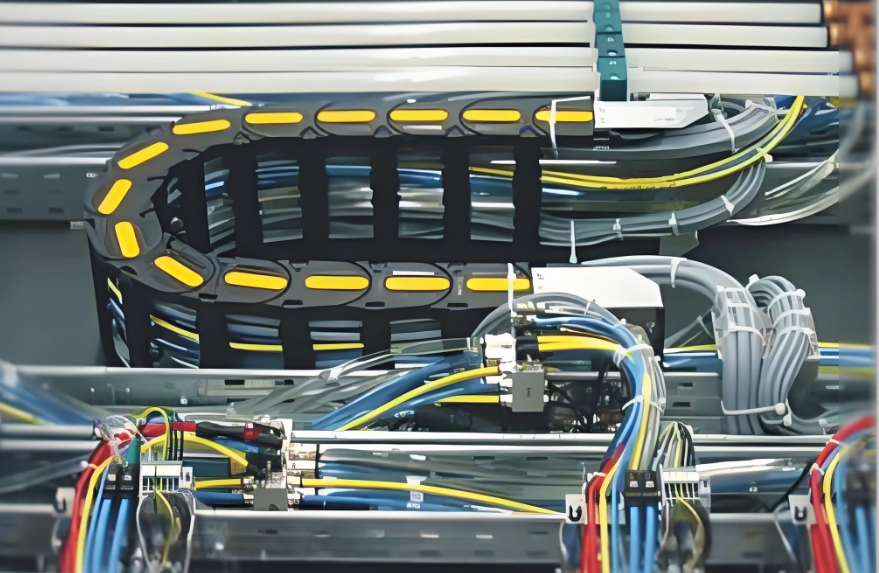

Drag chain cables are used in dynamic application environments to adapt to frequent movement and bending, such as automated production lines, robots, and machine tools.

Its design aims to protect flexible cable from mechanical stress and wear, ensuring the stability of signal transmission and power supply.

Key factors in selecting drag chain cables

1. Adaptability to working environment: The drag chain cable should be able to adapt to the working environment where the equipment is located, including high temperature, low temperature, humidity, oil pollution, and chemical corrosion. drag chain cables are made of high-performance materials that can resist the erosion of harsh environmental conditions, ensuring the long service life and high performance of the cables.

2. Mechanical performance requirements: The cable needs to have good flexibility and tensile strength to cope with frequent bending and movement. When selecting cables, the bending radius and bending resistance should be selected based on the equipment’s movement speed, acceleration, and stroke length to meet the requirements.

3. Electrical performance considerations: Electrical performance is an important indicator when selecting cables, directly related to the quality of signal transmission and the stability of power supply. Drag chain cable products use high-quality conductor materials and shielding technology to effectively prevent electromagnetic interference and signal attenuation, making them suitable for various complex industrial application scenarios.

The influence of materials and structures on drag chain cable performance

The material and structure of high flex cable determine its durability and performance. Drag chain cable adopts high-strength polyurethane (PUR) sheath material and multi-layer shielding design, which can prevent mechanical damage and effectively shield external electromagnetic interference.

Scientific structural design and high-quality material selection make cables less prone to aging during long-term use and able to withstand high-strength mechanical stress.

Installation and maintenance

Even if high-quality drag chain cables are chosen, proper installation and regular maintenance are important steps to ensure their performance.

During installation, it should be ensured that the bending radius of the high flex cable is not less than the recommended value, and the cable should be avoided from being squeezed or twisted in the drag chain.

Regular inspection of cable wear and timely replacement of aged or damaged cables can effectively extend the service life of equipment and avoid production stagnation caused by cable failures.

The role of drag chain cables in industrial automation equipment cannot be ignored, and correct selection and use can significantly improve the performance and reliability of the equipment.