This cable is particularly suitable for complex environments involving dancing robots, interactive robots, bionic robots, and other entertainment and sports robots. It can withstand continuous high-intensity bending, twisting mechanical stress, making it an excellent choice to ensure the reliability and long lifespan of robot products.

Parâmetro técnico

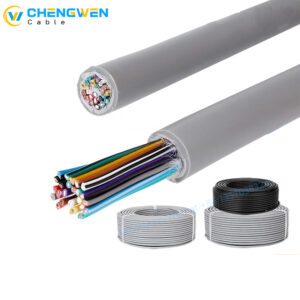

Telescopic robot twistable moving cables Structure

| TELESCOPIC ROBOT CABLE ( 50 million times reliability tests for drag chain) | ||||

| Não. | Código do produto | Número de núcleos e área transversal | Diâmetro externo aproximado (mm) | Cor da bainha externa |

| (NO.Xm㎡) | ||||

| 1 | RO-FP5001.10.0008 | 10×0.08 | 7.6 | Preto |

| 2 | RO-FP5002.16.0008 | 16×0.08 | 9,0 | Preto |