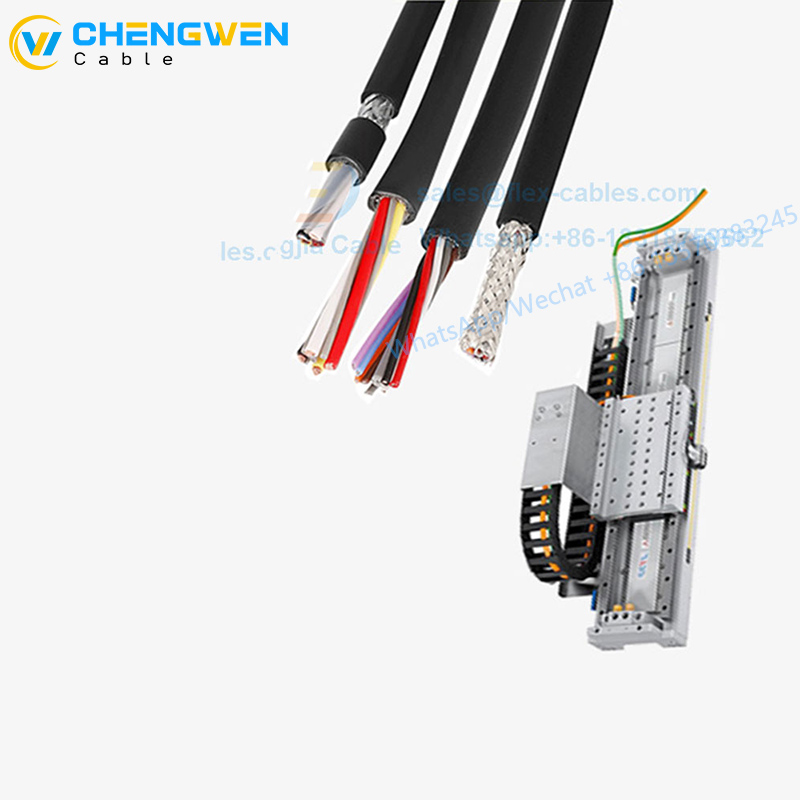

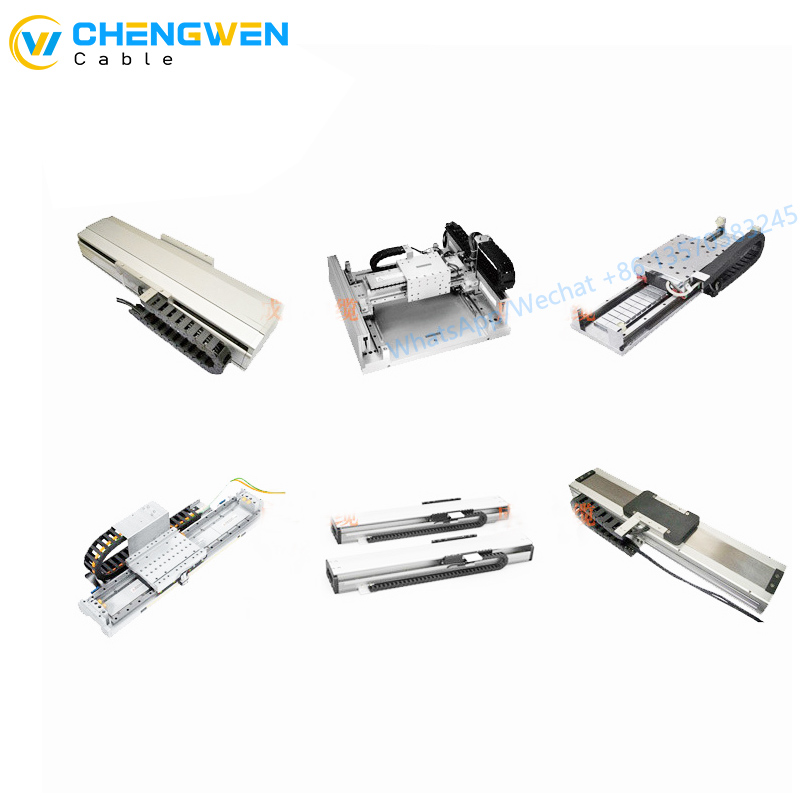

応用

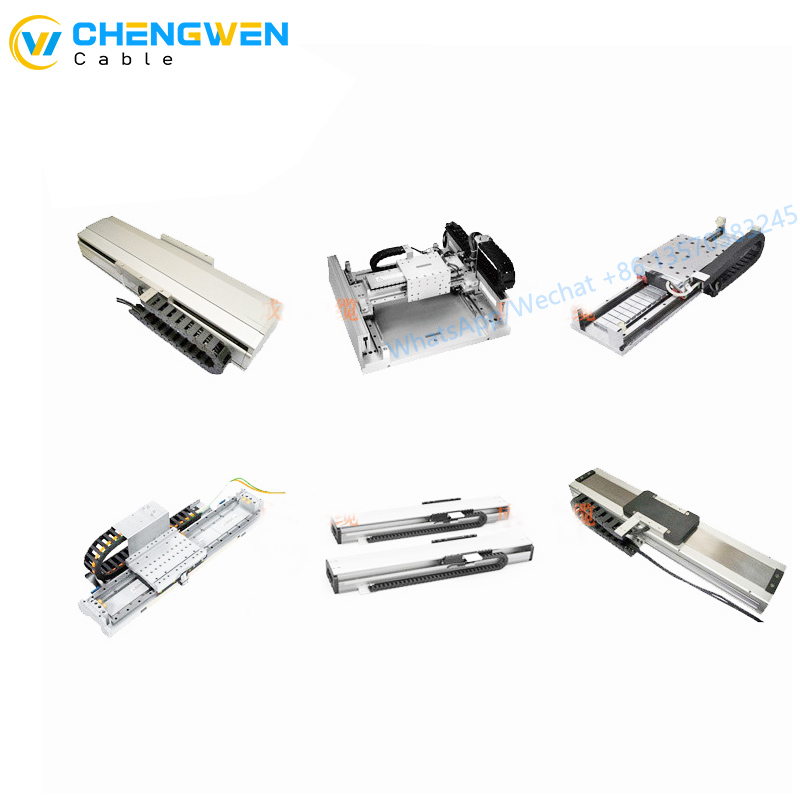

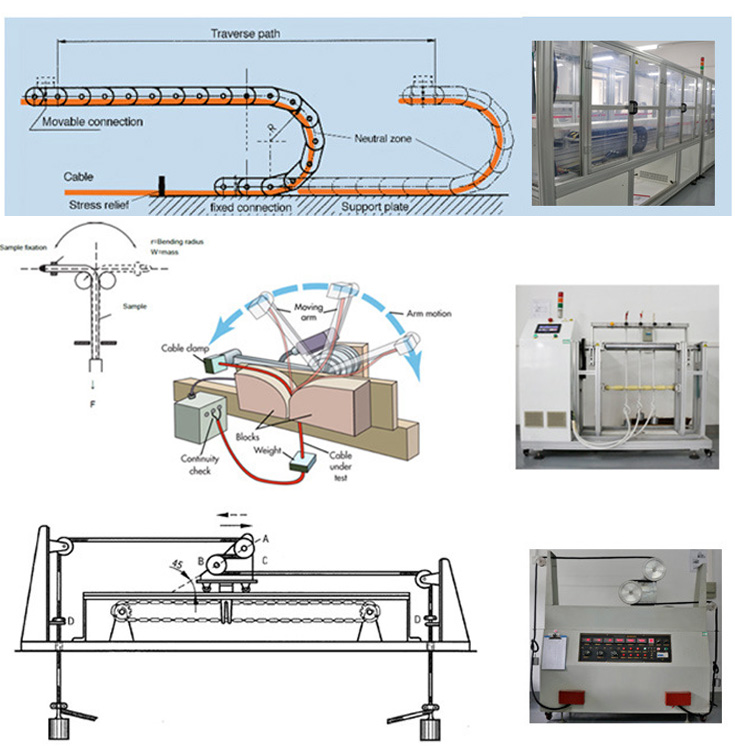

特に小型リニアモーターの長期高速ドラグチェーン、曲げ、高強度用途に最適です。リニアモーター用のケーブルは、機械的、化学的、熱的性能の点で最高の要件を満たさなければなりません。高速加減速、引張・圧縮応力、5,000万回を超える繰返し曲げなどに耐える必要があります。また、高温、金属の削りくず、油、その他の化学物質に対する耐性も必要です。

技術データ リニアサーボモータケーブル リニアモータワイヤ

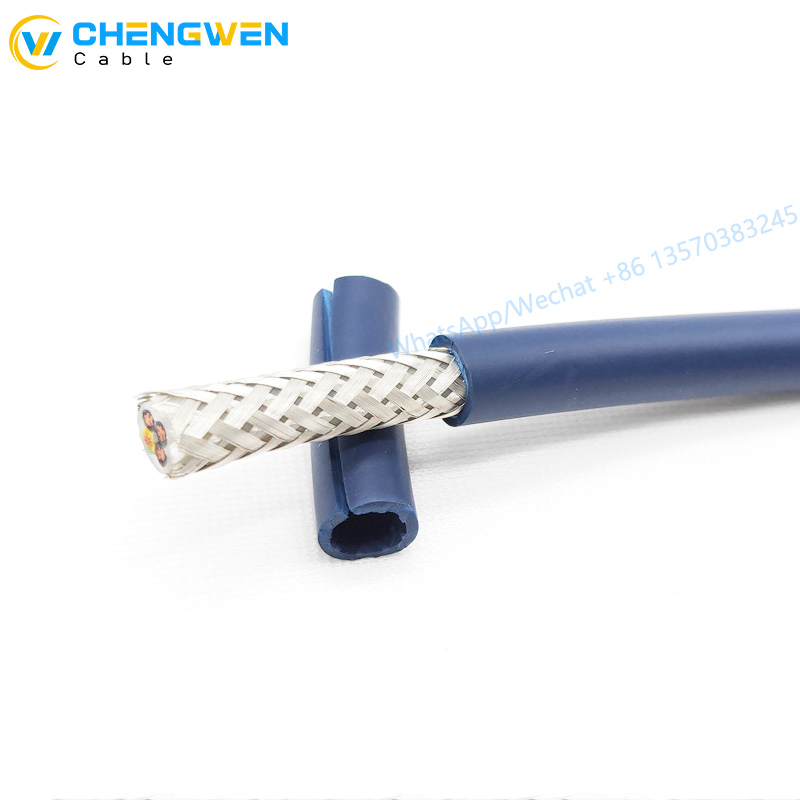

●特殊テフロン絶縁体と特殊PURシースにより超高強度と曲げ・ねじれ性能を実現

●TUV2 PfG 2577 クラス V 要件に準拠しています。

●温度範囲:移動設置の場合 -20℃~+80℃ 固定設置の場合 -40℃~+90℃

●公称電圧300/500V

●試験電圧2000V

●絶縁抵抗:最小100MOhm×km 最小曲げ半径:移動設置の場合はケーブル径の6倍、固定設置の場合はケーブル径の4倍

●EUのRoHSおよびReach規制に準拠しています。

●耐油性:耐油性に優れています(DIN EN50363-10-2規格に準拠)、Cass3。

●顧客の要求に応じて黒または色をカスタマイズできます。

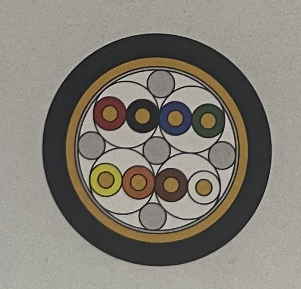

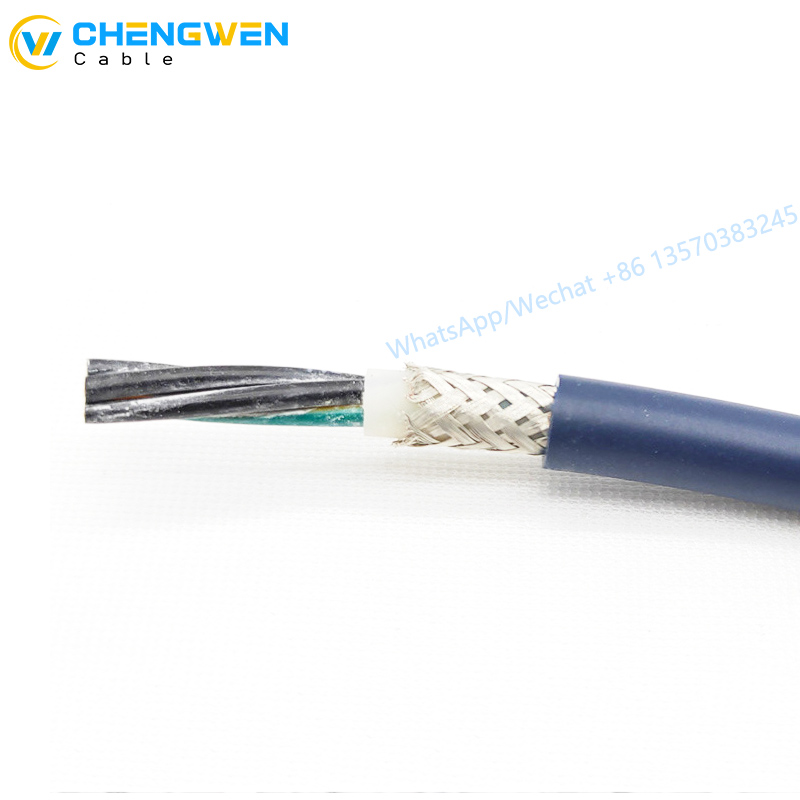

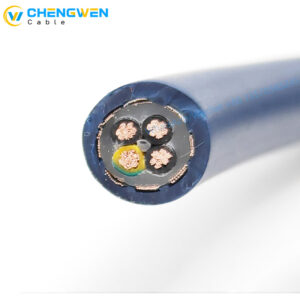

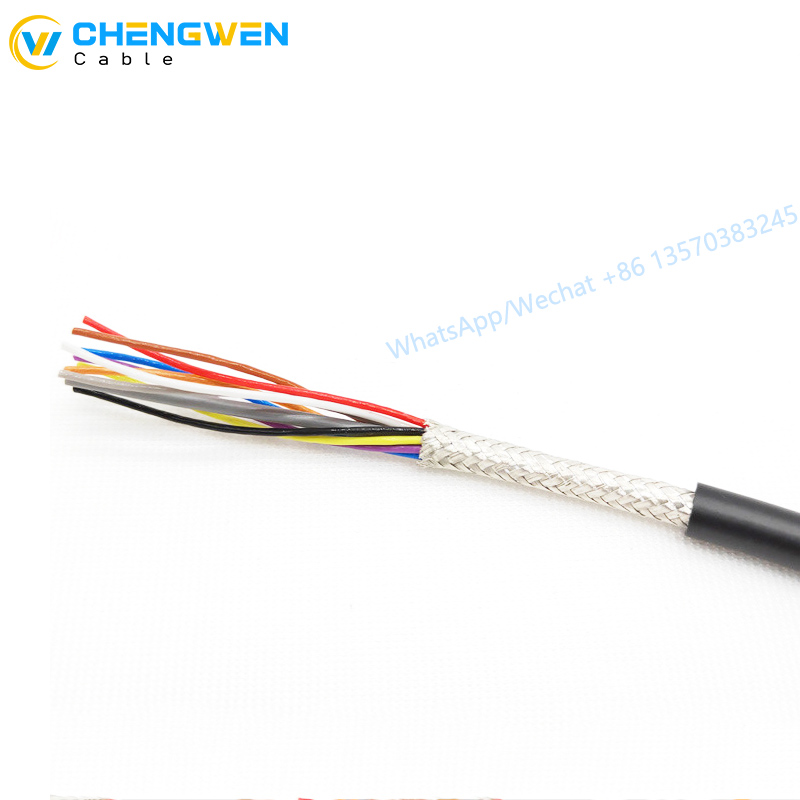

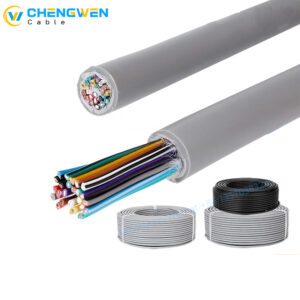

ケーブル構造

●裸銅導体、極細銅線 DIN VDE 0295 Class 6、IEC60228 Class 6に準拠

●特殊フッ素樹脂絶縁体

●芯線の色を色分けしています。

●最適ピッチ層撚り線

●改良型錫メッキ銅線編組シールド

● 最小カバレッジ 95%

●ドラッグチェーンでの使用に適した低摩擦のPURベースのコンパウンド(DIN 0281規格のパート10に準拠)。

| 超高速リニアモーターエンコーダーとコントロールケーブル (ドラッグチェーン5,000万回の信頼性試験) | ||||

| いいえ。 | 製品コード | コア数と断面積 | おおよその外径(mm) | 外被シース色 |

| (NO.Xm㎡) | ||||

| 1 | LM-FP5006.08.0020 | 4x2x0.2 | 6.4 | 黒 |

| 2 | LM-FP5002.08.0014 | 8×0.14 | 5.2 | 黒 |

| 3 | LM-FP5002.05.0014 | 5×0.14 | 4.2 | 黒 |