温度範囲:

ドラッグチェーン内移動時:-20℃~80℃

ドラッグチェーンの外側への移動: -40°C ~ 80°C

曲げ半径:

ドラッグ チェーン内での移動: 最小 7.5 xd

ドラッグ チェーンの外側への移動: 最小 6 xd

ドラッグチェーンの寿命:

ドラッグ チェーン内のケーブルの耐用年数に影響を与える要因:

温度、曲げ半径、移動距離、速度

TUV および安定したドラッグ チェーンのテスト基準:

温度範囲: +15°C ~ 25°C

曲げ半径:7.5×d

移動距離: 0.9メートル

速度: 90 サイクル/分

ドラッグ チェーンの寿命は 2,000 万サイクルに達します。

最高速度と加速度:

オーバーヘッド: 10 m/s スライド: 5 m/s 加速度: 80 m/s²3

移動距離:

頭上用途の場合、移動距離は 200 メートル未満

標準電圧: 600/1000V

試験電圧: 4000V

応用

特に、機械装置、工作機械、およびドラッグチェーンの連続的な高強度および高速曲げを伴うその他の用途に適しています。特に高速、長距離のドラッグチェーンでの使用に最適です。 TP200.08 シリーズドラッグチェーンケーブルは、倉庫設備、加工設備、梱包設備、屋内クレーン、ガラス設備、さらには梱包および物流業界の屋内ドラッグチェーンシステムに広く適用されています。

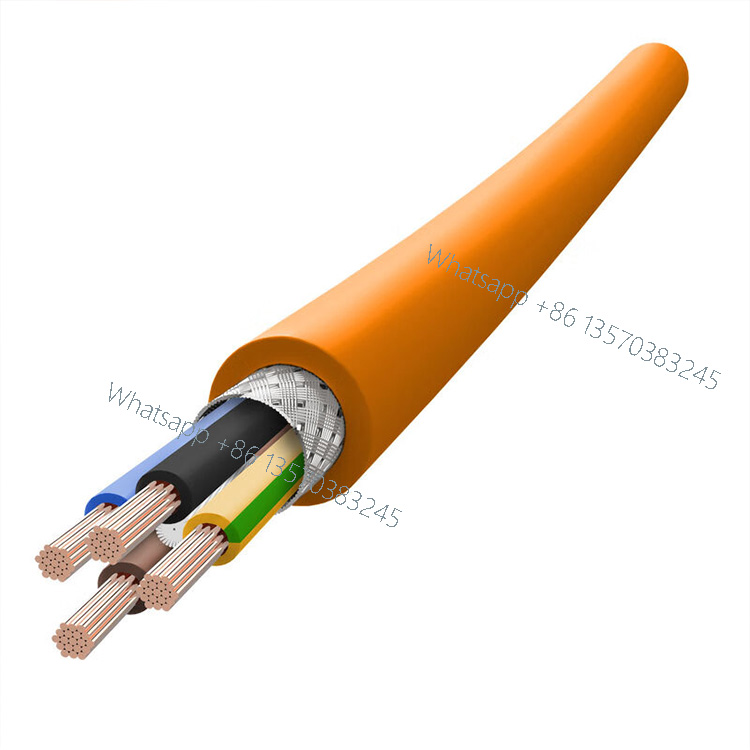

ケーブル構造

製品構造:

UL758 STYLE 20940に準拠

導体:

DIN VDE 0295 クラス 5 および IEC 60228 クラス 5 に準拠した、曲げ強度の高い細い裸銅より線

絶縁:

高い機械的性能 TPE ポリマー絶縁体

芯線の色:

単芯線の色は黒色です。

複数の芯線の組み合わせの場合、緑と黄色のアース線 1 本が、白い番号が付けられた黒い芯線とともに使用されます。

撚り合わせ方法:

ショートピッチ単層撚り。

内部シース: 変性 PUR ポリマー

全体のシールド: 高強度錫メッキ銅線シールド、光学カバー率 > 85%

アウタージャケット:

変性高強度PURポリマー

| アイテム | 製品コード | コア数と断面積 | おおよその外径 | 色 | 製品番号 | MOQ |

| 1 | TP200.08.01.0400 | 1×4.0 | 6.20 | オレンジ/ブラック | C-1350 | |

| 2 | TP200.08.01.0600 | 1×6.0 | 6.80 | オレンジ/ブラック | C-1351 | |

| 3 | TP200.08.01.1000 | 1×10.0 | 8.50 | オレンジ/ブラック | C-1352 | |

| 4 | TP200.08.01.1600 | 1×16.0 | 9.80 | オレンジ/ブラック | C-1353 | ※ |

| 5 | TP200.08.01.2500 | 1×25.0 | 11.20 | オレンジ/ブラック | C-1354 | ※ |

| 6 | TP200.08.01.3500 | 1×35.0 | 12.80 | オレンジ/ブラック | C-1355 | ※ |

| 7 | TP200.08.01.5000 | 1×50.0 | 15.20 | オレンジ/ブラック | C-1356 | ※ |

| 8 | TP200.08.01.7000 | 1×70.0 | 17.50 | オレンジ/ブラック | C-1357 | ※ |

| 9 | TP200.08.01.9500 | 1×95.0 | 20.00 | オレンジ/ブラック | C-1358 | ※ |

| 10 | TP200.08.04.0400 | 4G4.0 | 12.50 | オレンジ/ブラック | C-1361 | ※ |

| 11 | TP200.08.04.0600 | 4G6.0 | 14.50 | オレンジ/ブラック | C-1362 | ※ |

| 12 | TP200.08.04.1000 | 4G10.0 | 18.50 | オレンジ/ブラック | C-1363 |

注意事項

1.G = 黄緑アース線あり X = 黄緑アース線なし

2.American Wire Gauge (AWG) サイズはおおよその値です。実際の断面積が優先されます

3.外径10mmを超えるワイヤーは※指定品につき最低10mからご注文いただき、随時納品させていただきます。