Les câbles autoportants éliminent complètement le besoin d'un chemin de câbles ou d'une chaîne pour un système de gestion des câbles plus simple.

Nos câbles haute flexibilité sans rail résolvent de nombreux défis associés à la particule, aux vibrations, à la taille et au poids. Ils fournissent

précision de positionnement accrue, vitesses plus rapides, mouvement plus silencieux, installation fiable et fonctionnement plus propre

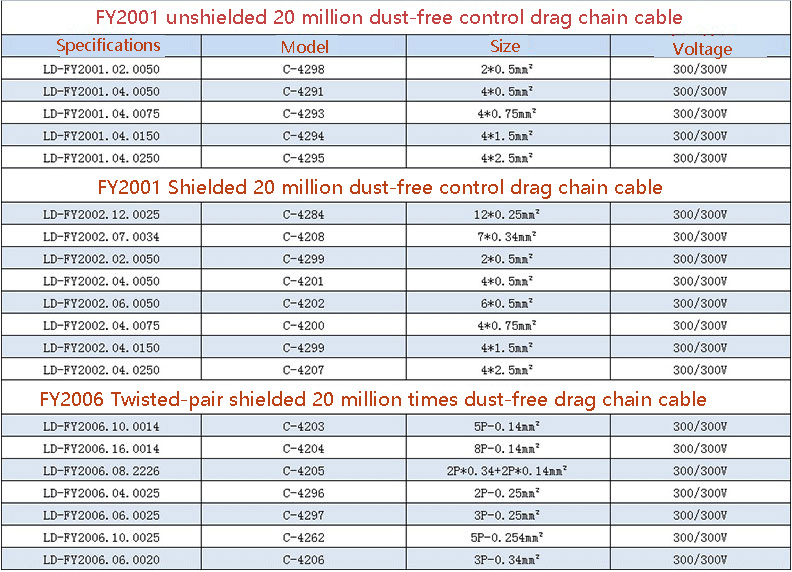

Paramètre technique des câbles hautement flexibles sans rail

|

Standard

|

Se conformer aux réglementations européennes RoHS et Reach

|

|||

|

Conducteur

|

Adopte un fil de cuivre toronné en cuivre étamé de haute qualité

|

|||

|

Matériau isolant

|

Composite PTFE expansé

|

|||

|

Écart de température:

|

Max. : 80 °C (176 °F)

Min. : -40 °C (-40 °F) |

|||

|

Longueur de course autoportante maximale [po (mm)]1

|

60 (1500)

|

|||

|

Couleur

|

Blanc

|

|||

|

Avantage

|

Antistatique/faible collecte de poussière/haute flexibilité/résistance à la flexion

|

|||

|

Tension nominale

|

Uo/U 300/300 V

|

|||

|

Rayon de courbure minimum [po (mm)]

|

1,0 à 4,0 (25,0 à 101,0)

|

|||

|

Classe salle blanche (classe salle blanche selon ISO 14644-1, 1 000 000 d'essais de flexion)b

|

Classe 1

|

|||

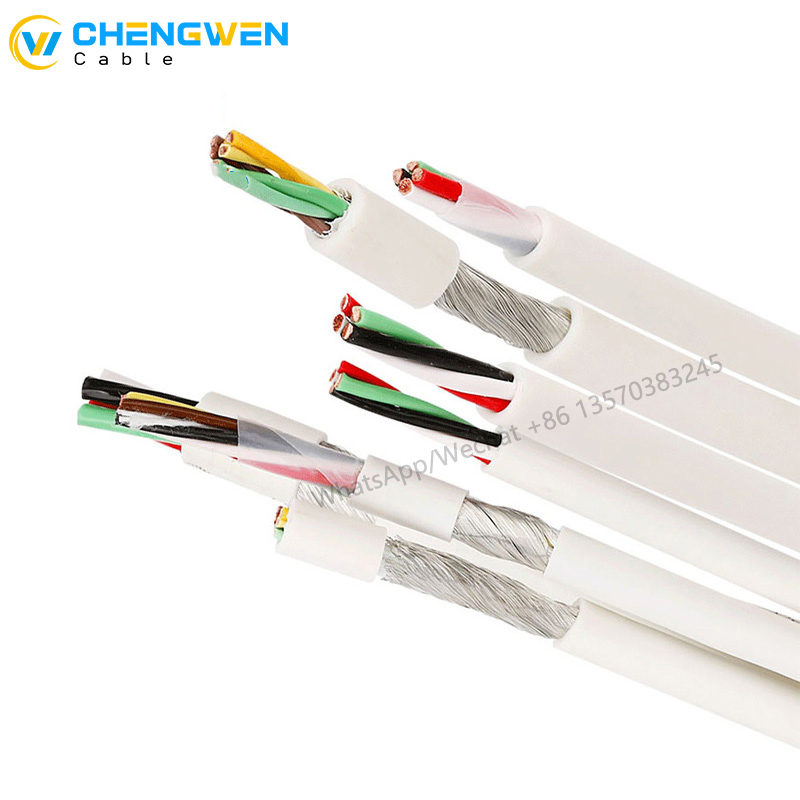

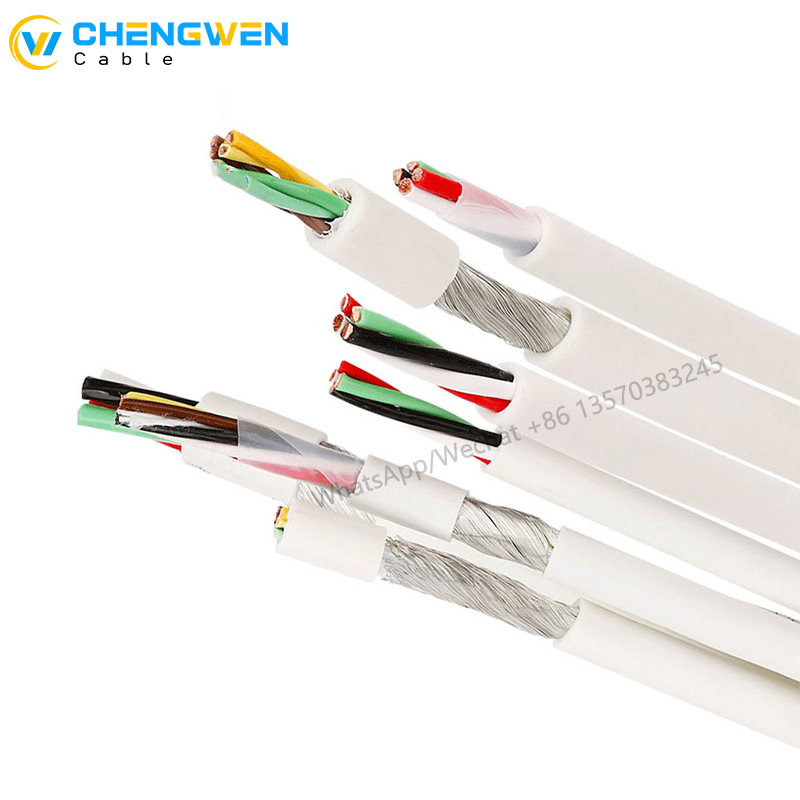

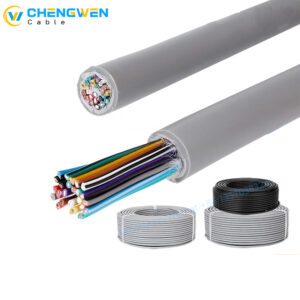

Structure de câbles hautement flexibles sans rail

Caractéristiques et avantages

Câbles High Flex sans rail qui les rendent plus durables dans les environnements exigeants.

* construction plate autoportante sans séparateurs ni étagères

* Durée de vie en flexion prouvée supérieure à 10 millions de cycles pour un rayon de courbure minimum de 50 millimètres

* matériaux isolants à faible friction, chimiquement inertes et sans particules

* certifié pour les environnements de salle blanche et de vide ISO classe 1

* configurations standard et personnalisées disponibles avec pinces de montageLes câbles haute flexibilité sans rail fournissent aux fabricants

* transmission fiable du signal dans des conditions environnementales difficiles

* Pas de particules ni de dégazage grâce aux matériaux de gainage et de blindage uniques

* élimine les vibrations causées par les chaînes et rails de câbles traditionnels

* installation facile grâce à des câbles légers et flexibles avec un rayon de courbure serré

* réduction de la maintenance, des temps d'arrêt et des coûts totaux sur le cycle de vie de l'équipement grâce à une durée de vie flexible éprouvée