Nos applications de câbles

Besoin d'aide?

Vous ne trouvez pas les modèles appropriés ici ? Il n'existe que quelques modèles populaires pour la ventilation des sièges, le tableau de bord et les phares. Contactez-nous pour obtenir le ventilateur DC adapté à vos besoins.

Contactez-nousÀ propos des solutions de câbles industriels dans l'industrie de l'automatisation

Les câbles pour chaînes porte-câbles jouent aujourd'hui un rôle crucial dans le domaine de l'automatisation industrielle. En tant que type spécial de câble, les câbles pour chaînes porte-câbles jouent un rôle important dans les équipements ou systèmes automatisés, contribuant de manière significative à l'amélioration de l'efficacité de la production et de la qualité des produits.

Premièrement, la fonction principale des câbles de chaîne porte-câbles dans les systèmes automatisés est de piloter des équipements ou des systèmes automatisés. Les équipements automatisés nécessitent souvent une grande quantité de puissance et de transmission de signaux, et les câbles de chaîne porte-câbles, en tant que câbles capables de résister à l'étirement et à la compression dynamiques, peuvent transmettre efficacement cette puissance et ces signaux. Dans les lignes de production automatisées, où les équipements doivent se déplacer et s'étendre fréquemment, les câbles fixes traditionnels sont sujets aux dommages et aux dysfonctionnements, tandis que les câbles à chaîne porte-câbles peuvent bien s'adapter à cet environnement dynamique et assurer une transmission stable de la puissance et du signal. Les câbles pour chaînes porte-câbles constituent donc une garantie vitale pour le fonctionnement normal des équipements automatisés.

Deuxièmement, l’importance des câbles de chaîne porte-câbles dans les systèmes automatisés se reflète dans leur contribution à l’amélioration de l’efficacité de la production et de la qualité des produits. Dans les lignes de production automatisées, les câbles de chaîne porte-câbles peuvent réduire efficacement les temps d'arrêt causés par des pannes de câbles, améliorant ainsi l'efficacité de la production. De plus, comme les câbles de chaîne porte-câbles peuvent assurer la transmission stable de la puissance et des signaux, ils améliorent la précision et la stabilité des équipements automatisés, améliorant ainsi la qualité du produit. De plus, l'utilisation de câbles de chaîne porte-câbles peut également réduire les coûts de main-d'œuvre, augmenter le niveau d'automatisation de la production et optimiser davantage les processus de production.

Cependant, la sécurité est de la plus haute importance lors de l’utilisation de câbles de chaîne porte-câbles. Les câbles de chaîne porte-câbles peuvent être soumis à divers facteurs environnementaux tels que la corrosion et l'usure lors d'un fonctionnement à long terme dans des systèmes automatisés. Par conséquent, des mesures anticorrosion et de protection sont essentielles pour garantir une utilisation sûre des câbles de chaîne porte-câbles. Premièrement, la sélection des matériaux pour les câbles de chaîne porte-câbles doit avoir une bonne résistance à la corrosion pour s'adapter à divers environnements difficiles. Deuxièmement, la conception structurelle des câbles de chaîne porte-câbles doit prendre en compte des mesures de protection, telles que le renforcement de la gaine extérieure des câbles pour éviter tout dommage externe. De plus, une inspection et un entretien réguliers sont également des moyens importants pour garantir une utilisation sûre des câbles de chaîne porte-câbles.

Voici quelques exemples d'applications pratiques de câbles pour chaînes porte-câbles dans l'automatisation industrielle :

Câbles de chaîne porte-câbles dans les machines-outils CNC : les machines-outils CNC sont des équipements essentiels dans la fabrication moderne, et leur haute précision et efficacité dépendent du support des câbles de chaîne porte-câbles. Par exemple, sur les fraiseuses, les câbles de chaîne porte-câbles peuvent transmettre différents types de signaux, notamment le mouvement axial, le débit du fluide de coupe, la vitesse de broche, etc., garantissant le fonctionnement normal et le contrôle précis de la machine-outil.

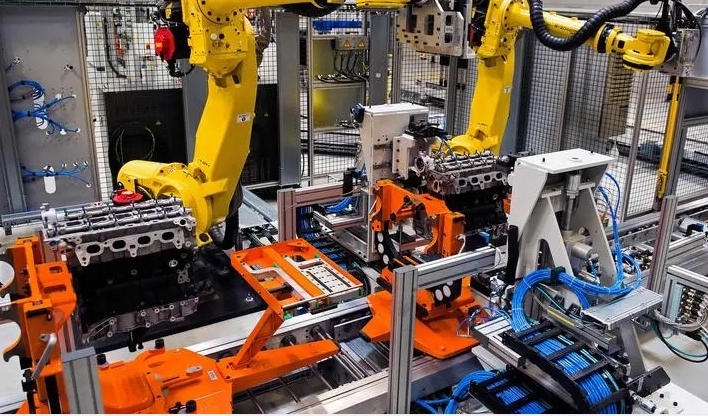

Câbles de chaîne porte-câbles dans les robots industriels : Les robots industriels sont largement utilisés dans des industries telles que l'automobile, l'électronique et l'alimentation, s'appuyant sur des câbles de chaîne porte-câbles pour la transmission de l'énergie et des signaux. Par exemple, dans les robots de soudage par points, les câbles de chaîne porte-câbles peuvent transmettre des signaux tels que la position du pistolet de soudage, le temps de soudage, la pression des électrodes, etc., garantissant ainsi la qualité du soudage et l'efficacité de la production.

Câbles de chaîne porte-câbles dans les lignes de production automatisées : les lignes de production automatisées se composent généralement de plusieurs postes de travail et équipements, nécessitant une grande quantité d'énergie et de transmission de signaux. Par exemple, dans les lignes de production automobile, les câbles de chaîne porte-câbles peuvent transmettre des informations d'assemblage pour divers composants du véhicule, des signaux de commande pour les systèmes hydrauliques, etc., permettant un fonctionnement efficace et une production optimisée.

Ces exemples d'applications pratiques démontrent l'importance et les divers domaines d'application des câbles pour chaînes porte-câbles dans l'automatisation industrielle. La fiabilité stable et la sécurité des câbles de chaîne porte-câbles constituent une base solide pour la modernisation et le développement intelligent de la production industrielle.