Servo motor power cable is a specialized electrical cable designed to transmit high-current electrical power from a servo drive (amplifier) to a servo motor. Its primary function is to deliver the precise voltage and current required to drive the motor windings and generate controlled torque and motion

Servo motor power cable Features:

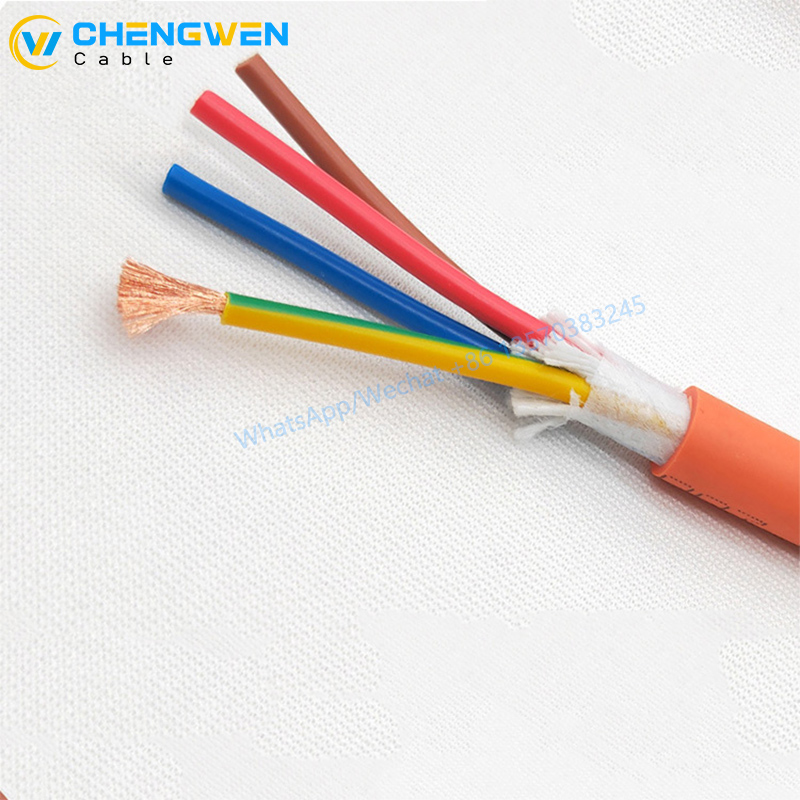

Conductors: Typically contains 2, 3, or 4 heavily stranded, fine-gauge copper conductors (often tinned for corrosion resistance). Stranding provides flexibility.

3 Conductors: Most common (U/V/W phases for 3-phase AC servo motors).

4 Conductors: Used for motors requiring a separate ground/earth conductor within the same cable (U/V/W + PE).

2 Conductors: Less common, sometimes for specific DC servo types or brake circuits.

Cách nhiệt: High-quality, durable insulation materials (e.g., PVC, PUR, TPE) rated for the motor voltage (commonly 300V, 600V, or 1000V) and resistant to oils, chemicals, abrasion, and temperature extremes (often rated -40°C to +80°C or higher).

Shielding: Robust overall braided or spiral shield (usually tinned copper) is essential. This: Contains electromagnetic interference (EMI) generated by the rapidly switching high currents in the cable. Protects the motor’s feedback signals (encoder/resolver) running in separate cables from electrical noise, ensuring accurate position/speed control.

Jacket (Sheath): A tough outer jacket made of materials like PUR (Polyurethane) or PVC (Polyvinyl Chloride). PUR is preferred for demanding applications due to its superior: Flexibility: Critical for continuous motion applications (robotics, CNC). Abrasion Resistance: Withstands rubbing against machinery. Oil & Chemical Resistance: Protects against industrial contaminants. Tear Resistance: Prevents damage during installation/use.

Flexibility: Designed for high-flex or continuous flex applications common with servo systems in automation and robotics. Fine stranding and specialized jacket materials achieve this.

Connectors: Terminates in industry-standard connectors compatible with the servo drive output and motor input (e.g., circular connectors like M23, M17, M12; rectangular types; or sometimes flying leads for direct termination). Proper grounding/shield termination at BOTH ends is crucial for noise immunity.

| Sản phẩm | Mục | Người mẫu | Đặc điểm kỹ thuật | CỦA | Màu sắc | Đánh dấu |

| Flexible servo power cable (2 million times reliability tests for drag chain) | 1 | YY07.02.0050 | 2*0.5mm2 | 5,6 | Đen | China standard core wire colors: blue, brown, red, yellow/green |

| 2 | YY07.04.0050 | 4*0.5mm2 | 6,5 | Đen | ||

| 3 | YY07.04.0075 | 4*0.75mm2 | 7.2 | Đen | ||

| 4 | YY07.04.0100 | 4*1.0mm2 | 7,8 | Đen | ||

| 5 | YY07.04.0150 | 4*1.5mm2 | 9 | Đen | ||

| 6 | YY07.04.0250 | 4*2.5mm2 | 11 | Đen | ||

| 7 | L-YY07.02.0050 | 2*0.5mm2 | 5,6 | Đen | Màu dây lõi tiêu chuẩn UL: đen, trắng, đỏ, vàng / xanh | |

| số 8 | L-YY07.04.0050 | 4*0.5mm2 | 6,5 | Đen | ||

| 9 | L-YY07.04.0075 | 4*0.75mm2 | 7.2 | Đen | ||

| 10 | YY07.04.0130 | 4*1.3mm2 | 8.3 | Đen | ||

| 11 | YY07.04.0200 | 4*2.0mm2 | 10 | Đen | ||

| 12 | MC-YY07.04.0050 | 4*0.5mm2 | 6.3 | Đen | Gecko head power cord, UL printed, core Wire colors black, white, red, yellow/green |

|

| 13 | MC-YY507,06.2024 | 4*0.5+2*0.2 | 6.3 | Đen |