Ứng dụng cáp của chúng tôi

Có cần giúp gì không?

Không thể tìm thấy các mô hình phù hợp ở đây? Chỉ có một số mẫu phổ biến về thông gió ghế, bảng điều khiển và đèn pha. Hãy liên hệ với chúng tôi để có được chiếc quạt DC phù hợp với nhu cầu của bạn.

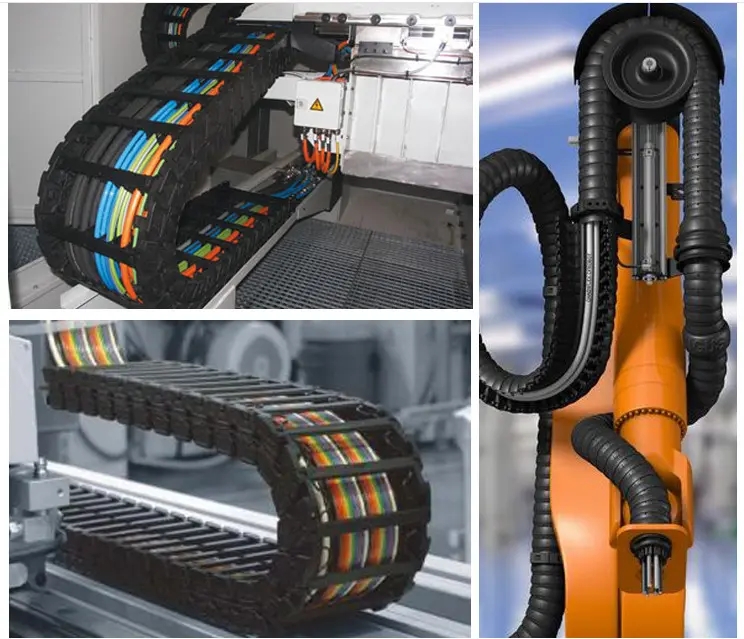

Liên hệ chúng tôiApplication of Drag Chain Cables in CNC Machine Tools

CNC machine tools are essential equipment in modern manufacturing industry, utilizing precise control systems for automated processing. In the operation of CNC machine tools, drag chain cables play a crucial role.

Drag chain cables are designed specifically for transmitting power and signals within moving components. In CNC machine tools, where high-speed and high-frequency movements and twists are common due to various axis motions, tool cutting, and sensor signal requirements, drag chain cables must maintain stable data transmission and power supply.

Firstly, drag chain cables facilitate power transmission in CNC machine tools. These machine tools are typically equipped with multiple drive motors that provide the necessary power to drive various moving parts. Drag chain cables carry high current loads, transmitting electrical energy to the drive motors through cable cores and conductors, ensuring smooth operation of the machine tools.

Additionally, drag chain cables are responsible for transmitting various signals. CNC machine tools require the transmission of signals such as position feedback, temperature sensors, pressure sensors, etc., to achieve precise control and monitoring. With multi-core cables, drag chain cables can simultaneously transmit different types of signals, ensuring accurate data transfer.

The application of drag chain cables in CNC machine tools also requires specific performance characteristics. Wear resistance is essential due to the high-frequency movements of the machine tools, requiring the cables to withstand prolonged friction and wear to maintain optimal performance. Oil resistance is another crucial factor, as CNC machine tools often involve lubricants and coolant fluids, necessitating cables that can resist oil contamination and damage. Moreover, drag chain cables must exhibit high temperature resistance, tensile strength, and fire resistance to withstand harsh working environments.

In conclusion, drag chain cables play a vital role in CNC machine tools by providing stable power supply and signal transmission, ensuring the efficient operation and production of the machine tools. As CNC technology advances and machine tool performance improves, the demand for drag chain cables continues to rise, prompting the development of more advanced materials and designs to meet the increasingly complex requirements of CNC machine tools.

In summary, drag chain cables have significant application significance in CNC machine tools, serving as a key connectivity solution for achieving automation and precision machining in machine tools. By delivering stable power and signal transmission, drag chain cables make important contributions to the efficient operation and high-quality production of CNC machine tools. Moving forward, with technological advancements, drag chain cables will continue to evolve, bringing more innovation and progress to the CNC machine tools industry.