ロボット用途 電力および信号 スカラロボットケーブル

このタイプのロボット ケーブルは、長期間のねじれ、曲げ、高強度の用途が必要な複雑な環境で動作するスカラ ロボットやその他の機械に特に適しています。曲げやねじりによる継続的かつ高強度の機械的ストレスに耐えることができるため、ロボット製品の信頼性と寿命の延長を確保するための優れた選択肢となります。

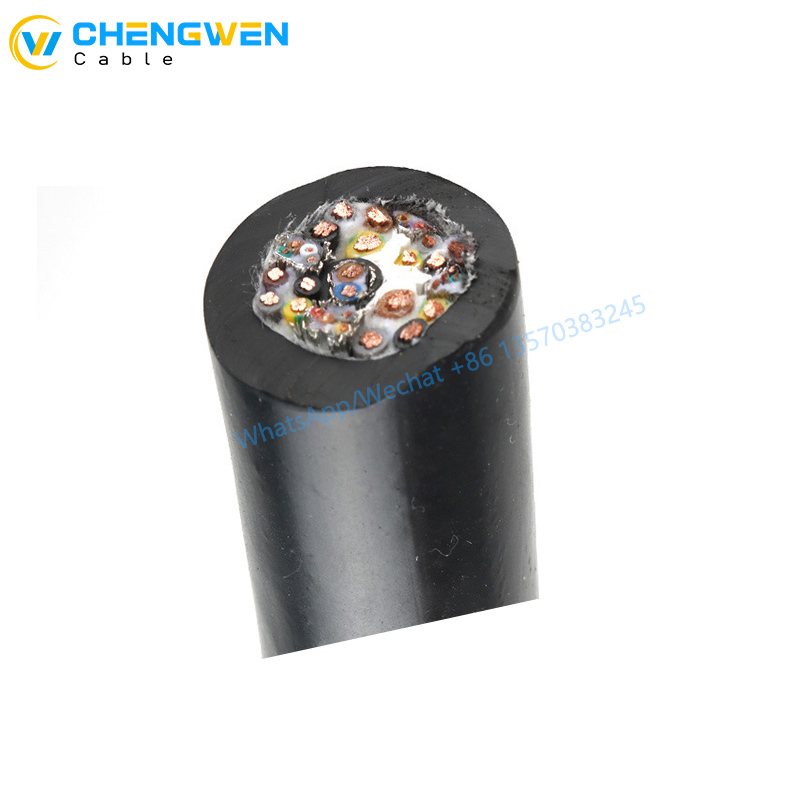

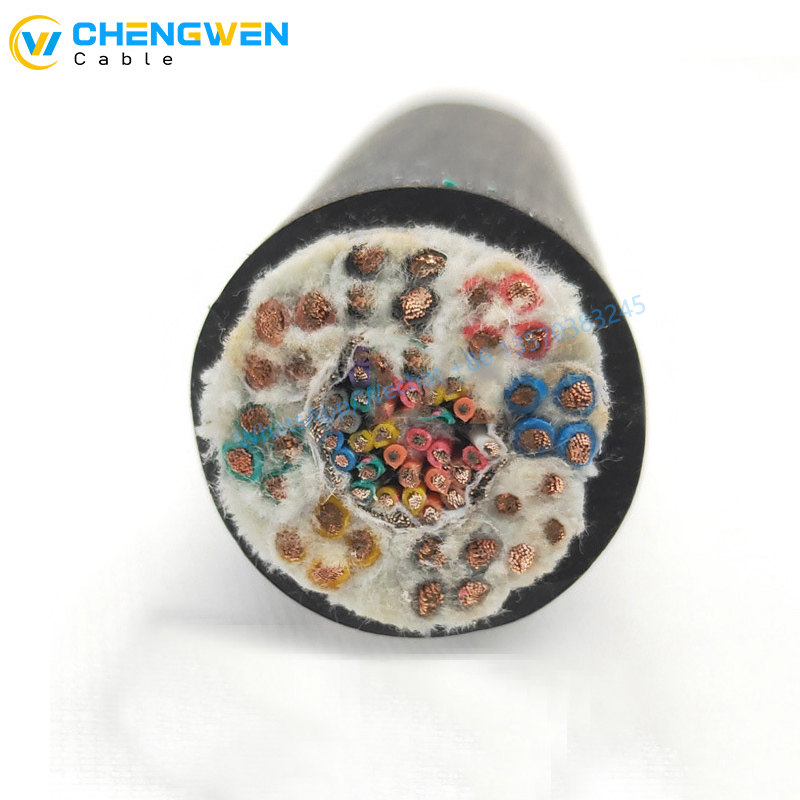

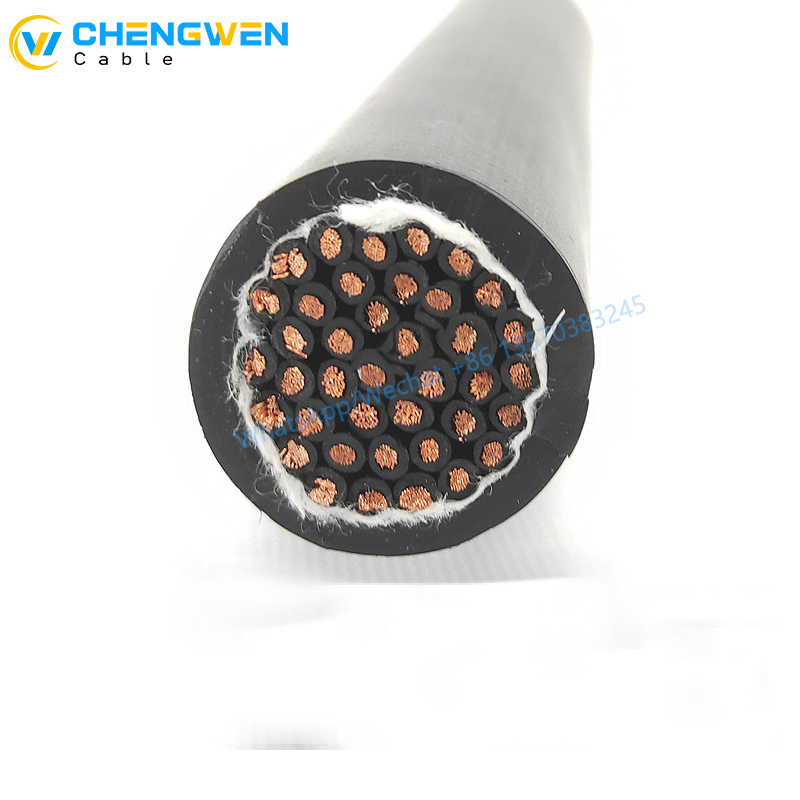

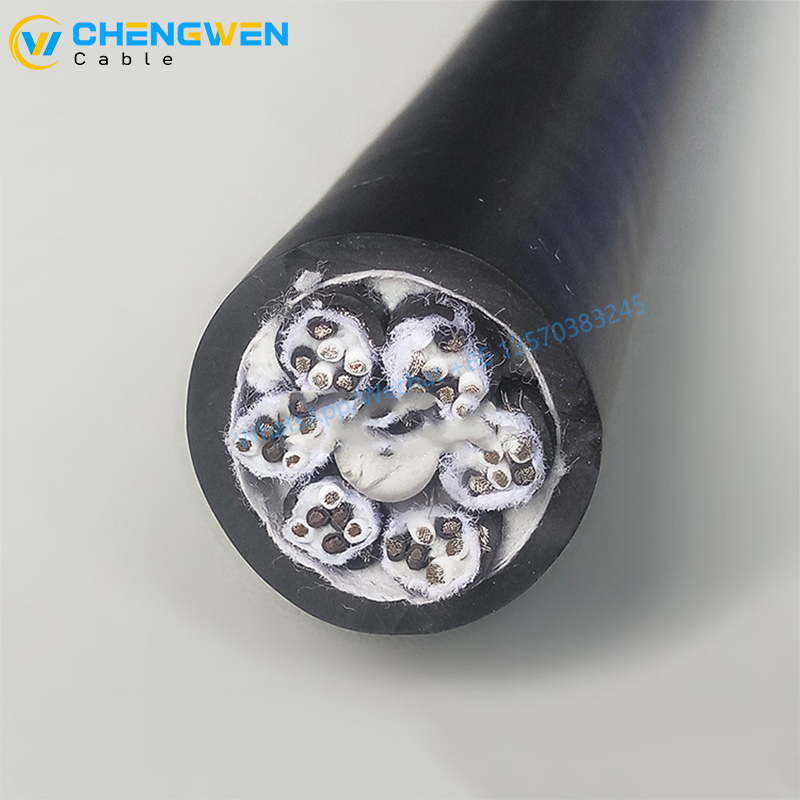

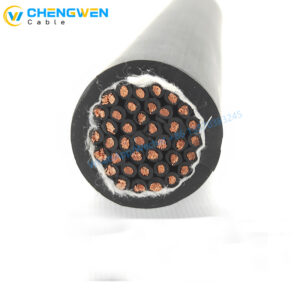

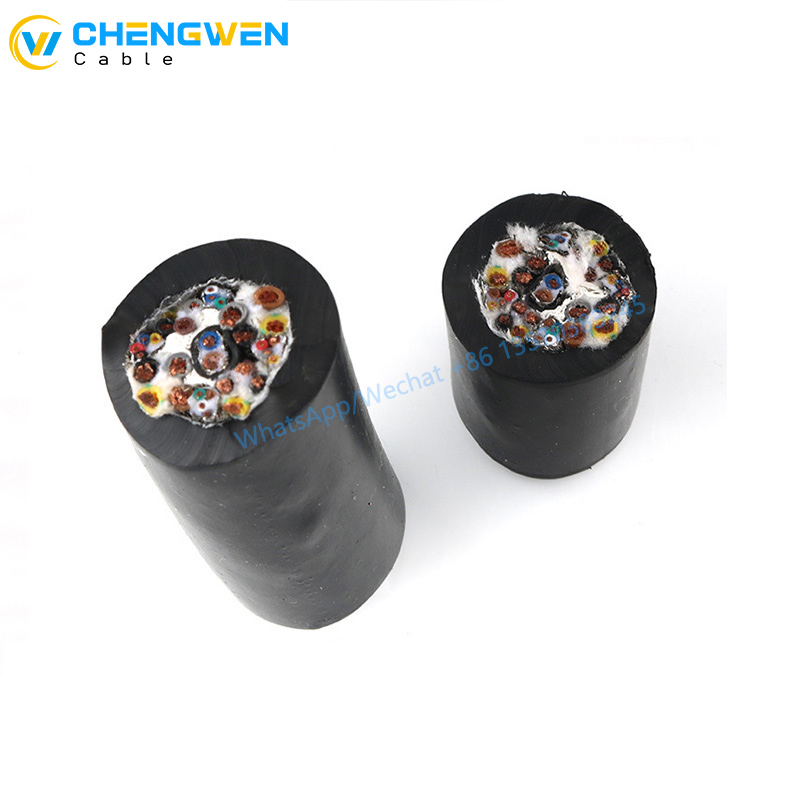

構造

●錫メッキ銅(0.5mm2未満)または裸銅(0.5mm2以上)導体、極細銅線、DIN VDE 0295クラス6およびIEC 60228クラス6に準拠。

●特殊フッ素樹脂絶縁です。

●芯線を色分けしています。

●芯線の最適ピッチ撚り。

●改良された錫メッキ銅線編組シールド。

● 最小カバー率 85%。

●特殊PVC外装シース。

●マットな仕上がりのブラック色(RAL9005)です。

| 産業用ロボット用ドラッグチェーンケーブル(ドラッグチェーン5,000万回信頼性試験) | ||||

| いいえ。 | 製品コード | コア数と断面積 | おおよその外径(mm) | 外被シース色 |

| (NO.Xm㎡) | ||||

| 1 | RO-FY2001.56.2417 | 3X(4x2x0.2)+(7x2x0.2+3x(6×1.0)+2xチューブ | 24.5 | 黒 |

要件に応じた特別なモデルのカスタマイズが利用可能です。さまざまな導体断面積、材料、シールド、色、鞘のその他の仕様を備えたケーブルなどです。

2.2Dねじりテスト

テスト方法:2.5メートルの仕上げケーブルを取り、距離を1メートルで固定し、指定された重量を適用し、角度を正と負の90度または180度で回転させ、毎分60サイクルの速度でねじれを実行します。

判断基準:1。5,000,000サイクルの前後の動きを超えた後の開回路または短絡はありません。 2.鞘のひび割れはありません。

3.3Dねじりテスト

テスト方法:1メートルの仕上げケーブルを取り、標準要件に応じて距離を修正します。上部は正と負の90度で曲がっていますが、ベースは正と負の180度で回転します。毎分30サイクルの速度で曲げとねじれを実行する

判断基準:1。5,000,000サイクルの前後の動きを超えた後の開回路または短絡はありません。 2.鞘のひび割れはありません。

4.二輪曲げテスト

テスト方法:5メートルの仕上げケーブルを取り、指定されたプーリーの直径と重量に応じて、少なくとも1.0メートルの移動距離で速度0.33メートルの速度でプーリーを前後に動かします。判断基準:

判断基準:1。1,000,000サイクルの前後の動きを超えた後の開回路または短絡はありません。 2.鞘のひび割れはありません。

5.90度ベンドテスト

テスト方法:ケーブル直径の2.5倍の曲げ半径を持つ2メートルの仕上げケーブルを取り、標準で指定された重量を適用し、毎分40サイクルの速度で曲げを実行します。

判断基準:1。1,000,000サイクルの前後の動きを超えた後の開回路または短絡はありません。 2.鞘のひび割れはありません。

6.増加および回転テスト

テスト方法:1.5メートルの仕上げケーブルを使用し、距離を300mmで固定し、曲げ半径は150mmで、1分あたり50回転の速度で回転します。

判断基準は、50,000サイクルの往復運動を超えた後の開回路または短絡なし。鞘にひびが入りません。