Oil resistant PUR cable

| YP502 HIGH FLEXIBLE PUR DRAG CHAIN CONTROL SHIELD CABLE(Color Core) (ドラッグチェーンの信頼性試験500万回)) | ||||

| いいえ。 | 製品コード | コア数と断面積 | おおよその外径(mm) | 外被シース色 |

| (NO.Xm㎡) | ||||

| 1 | YP502.03.0014 | 3×0.14 | 4.2 | 黒 |

| 2 | YP502.04.0014 | .4×0.14 | 4.5 | 黒 |

| 3 | YP502.06.0014 | 6×0.14 | 5.2 | 黒 |

| 4 | YP502.08.0014 | 8×0.14 | 6 | 黒 |

| 5 | YP502.10.0014 | 10×0.14 | 6.8 | 黒 |

| 6 | YP502.12.0014 | 12×0.14 | 6.5 | 黒 |

| 7 | YP502.16.0014 | 16×0.14 | 7.2 | 黒 |

| 8 | YP502.20.0014 | 20×0.14 | 7.8 | 黒 |

| 9 | YP502.26.0014 | 26×0.14 | 9.0 | 黒 |

| 10 | YP502.02.0020 | 2×0.2 | 4.4 | 黒 |

| 11 | YP502.03.0020 | 3×0.2 | 4.6 | 黒 |

| 12 | YP502.04.0020 | 4×0.2 | 4.9 | 黒 |

| 13 | YP502.05.0020 | 5×0.2 | 5.2 | 黒 |

| 14 | YP502.06.0020 | 6×0.2 | 5.6 | 黒 |

| 15 | YP502.08.0020 | 8×0.2 | 6.5 | 黒 |

| 16 | YP502.10.0020 | 10×0.2 | 7.4 | 黒 |

| 17 | YP502.12.0020 | 12×0.2 | 7.0 | 黒 |

| 18 | YP502.16.0020 | 16×0.2 | 7.8 | 黒 |

| 19 | YP502.20.0020 | 20×0.2 | 8.5 | 黒 |

| 20 | YP502.26.0020 | 26×0.2 | 9.5 | 黒 |

| 21 | YP502.30.0020 | 30×0.2 | 9.8 | 黒 |

| 22 | YP502.02.0030 | 2×0.3 | 4.6 | 黒 |

| 23 | YP502.03.0030 | 3×0.3 | 4.8 | 黒 |

| 24 | YP502.04.0030 | 4×0.3 | 5.1 | 黒 |

| 25 | YP502.05.0030 | 5×0.3 | 5.5 | 黒 |

| 26 | YP502.06.0030 | 6×0.3 | 5.8 | 黒 |

| 27 | YP502.08.0030 | 8×0.3 | 6.8 | 黒 |

| 28 | YP502.10.0030 | 10×0.3 | 7.8 | 黒 |

| 29 | YP502.12.0030 | 12×0.3 | 7.4 | 黒 |

| 30 | YP502.16.0030 | 16×0.3 | 8.2 | 黒 |

| 31 | YP502.20.0030 | 20×0.3 | 9.0 | 黒 |

G=は黄緑色のアース線を表します。詳しい仕様や特別なカスタム製品については、当社の製品コンサルタントにお問い合わせください。

Oil resistant PUR cable 技術データ

●特殊なPURシース、非常に柔軟です

●Tem perature range: Mobile installation: -20°C to +80°C Fixed installation: -40°C to +90°C

●最大オーバーヘッド/スライド速度:5 m/s、3 m/s

●最大加速:50 m/s

●公称電圧UO/U:300/300V

●テスト電圧:1500V

●絶縁抵抗:最小20MOhmxkm

●最小曲げ半径:移動設置時:7.5×ケーブル径 固定設置時:6×ケーブル径

●EU ROHSに準拠し、規制に到達します

●油抵抗:完全に油耐性

●火炎遅延:IEC 60332-1-2、CEI 20-35、FT1、VW-1に準拠しています

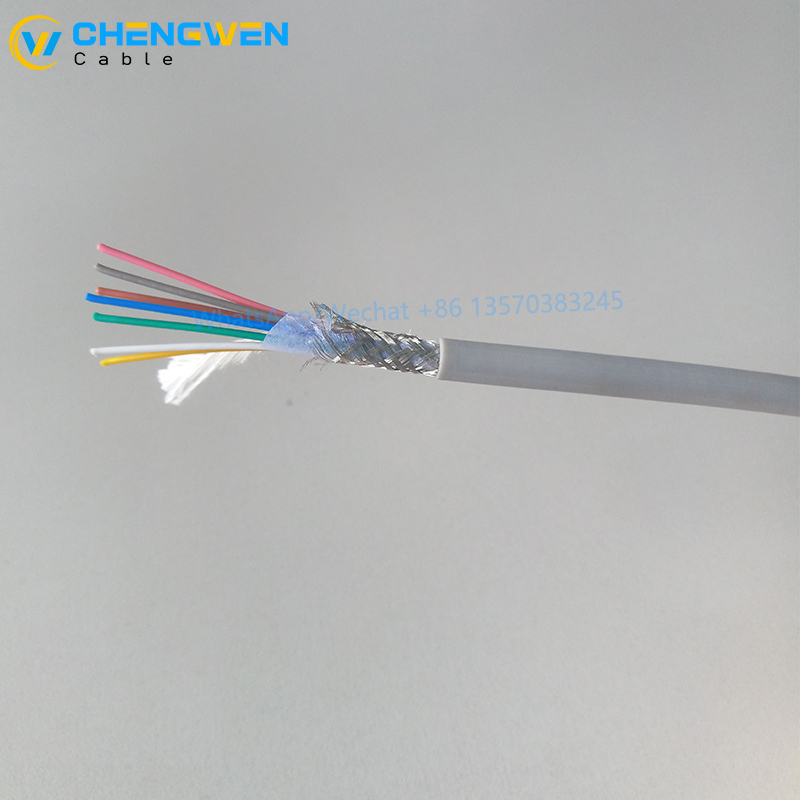

Oil resistant PUR cable Structure:

●Tinned copper (below 0.5mm²) or bare copper (0.5mm² and above) conductors Fine copper wire, compliant with DIN VDE 0295 Class 6 and IEC 6 0228 Class 6

●特殊PVC絶縁体

●色分けされたコア(0.5mm²未満)

●Black cores with continuous white numeric marking (0.5mm² and above) Yellow-green grounding wire in outer layer (3 cores and above)

●Optimal pitch twisted stranded cores

●強化された缶詰銅線の編組シールド

●Minimum coverage 85%

●アウターシース ドラグチェーンの要求に合わせ調整された低粘着PUR配合。

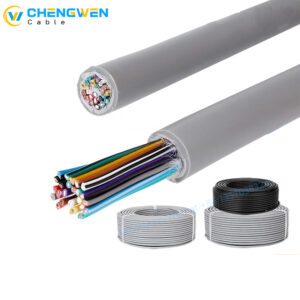

●色: グレー、黒、または顧客の要件に応じて色を合わせることができます。

| 高柔軟性500万回ドラッグチェーンケーブルテスト基準 | ||

| ドラッグチェーン曲げテスト テスト方法:ケーブルの外径の6倍の曲げ半径、900 mmの移動ストローク、および90倍/分の速度での往復運動を備えた2メートルの仕上げケーブルを取ります。 |

二輪巻きテスト テスト方法:指定されたプーリーの直径と重量の重量に応じて、5メートルの仕上げケーブルを取ります。プーリーは0.33 m/秒の速度で移動し、移動距離は往復条件下で1.0メートル以上です |

90度ベンドテスト テスト方法:2メートルの仕上げケーブルを取り、ケーブルの外径の2.5倍の曲げ半径を使用します。 |

| 判断基準:1。往復の数は、開回路または短絡がない場合は5,000,000倍を超えます。 2。鞘は壊れていません | 判断基準:1。往復の数は、開回路または短絡がない限り200,000倍を超えます。 2。鞘は壊れていません | 判断基準:1。往復の数は、開回路または短絡がない場合は100,000倍を超えます。 2。鞘は壊れていません |