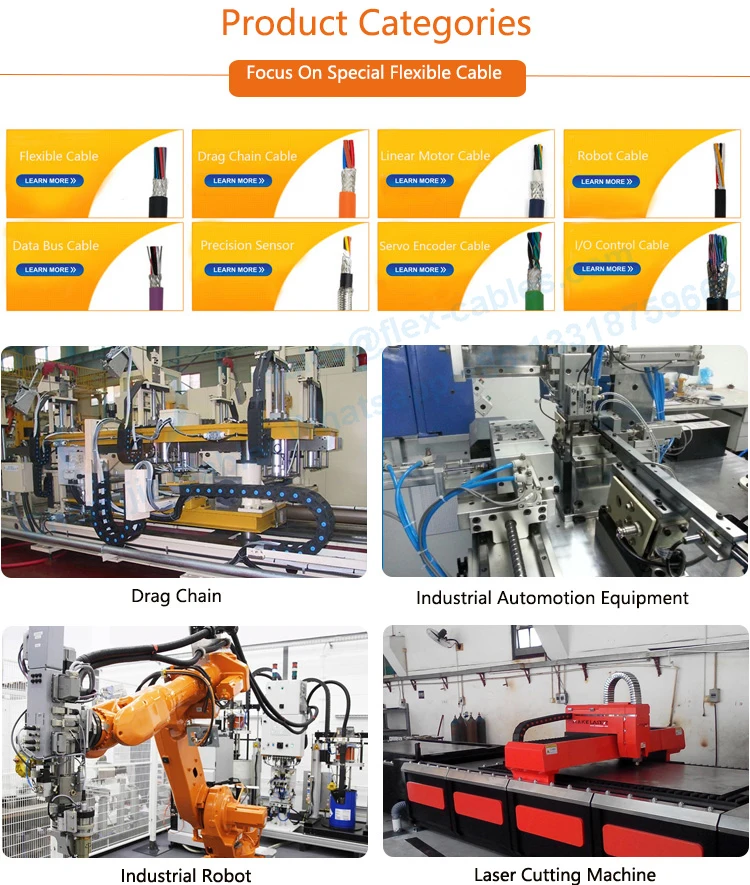

応用

●導体は0.08mmの極細銅線を集団で撚り合わせたラップ構造を採用しており、優れた柔軟性を確保しています。

●信号干渉を最小限に抑える錫メッキ銅線編組シールド層を採用しています。

●非常に過酷な産業環境や腐食性クーラント、潤滑油が使用される場所に適し、優れた耐油性、耐摩耗性を発揮します。

●微生物、加水分解、化学腐食、紫外線、低温に対して優れた耐性を持っています。

●屋内および屋外の乾燥または多湿な条件で使用でき、特に産業環境に適しています。

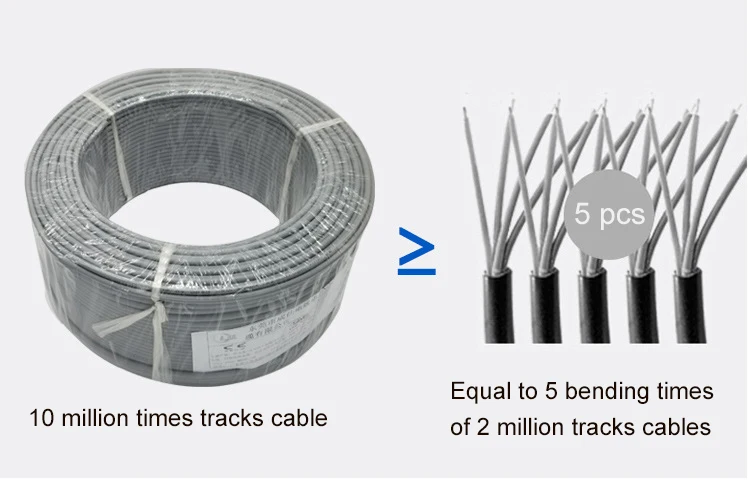

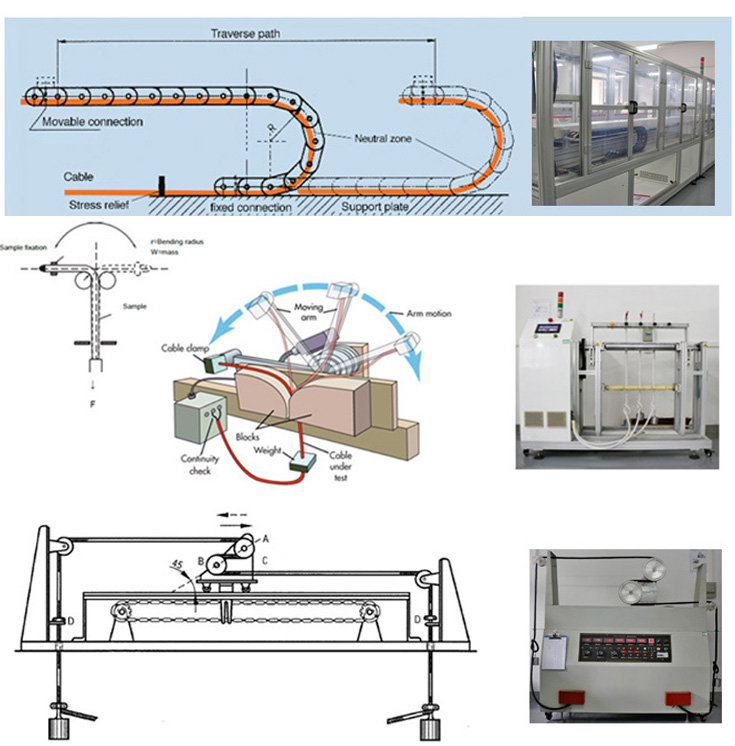

●通常の使用条件下で一般に1,000万回以上の寿命を誇り、高速動作するドラッグチェーンの使用に適しています。

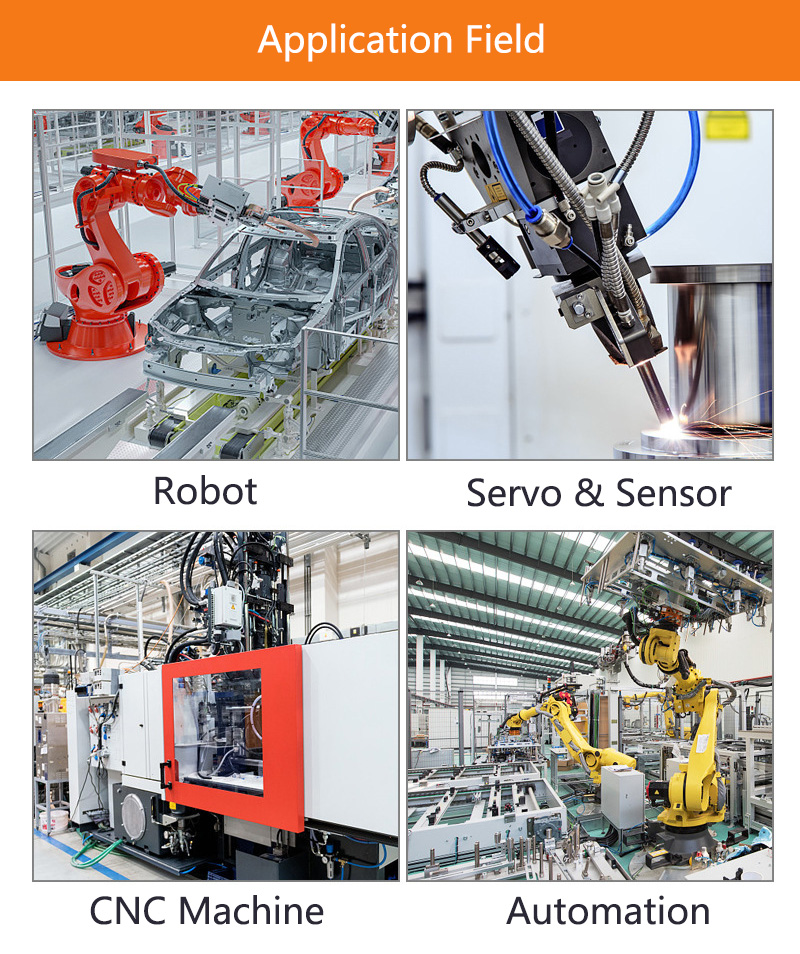

●主に過酷な環境で動作する産業オートメーション、電気機械機器、工作機械、物流機器、サーボシステムなどの動力伝達に使用されます。

技術データ

●特殊なPURシース、非常に柔軟です

●温度範囲:モバイルインストール:-20°C〜 +80°C固定設置:-40°C〜 +90°C

●最大オーバーヘッド/スライド速度:5 m/s、3 m/s

●最大加速:50 m/s

● Test voltage: 2000V \

●絶縁抵抗:最小20MOhmxkm

● 最小曲げ半径: 移動式設置: 6 x ケーブル直径 固定設置: 4 x ケーブル直径

●耐油性:完全耐油性

●EUのRoHSおよびReach規制に準拠しています。

●難燃性、IEC 60332-1-2、CEI 20-35、FT1、VW-1に準拠しています。

ケーブル構造

● 0.08mm² 裸銅導体、極細銅線

●DIN VDE 0295 クラス6、IEC 60228 クラス6に準拠。

●特殊PVC絶縁体

●色分けされたコア。

●最適ピッチ同心より線コア

●黄緑色アース線付(3芯以上)。

●改良された錫メッキ銅線編組シールド

●カバー率90%以上

●低摩擦、耐摩耗性、耐低温性、耐油性に優れたPUR複合素材です。

●顧客の要求に応じて黒、オレンジまたは色をカスタマイズすることができます。

| YP1008 超高柔軟性 PUR シールド付きドラッグチェーンパワーケーブル (ドラッグチェーンの信頼性テスト 1,000 万回) | ||||

| いいえ。 | 製品コード | コア数と断面積 | おおよその外径(mm) | 外被シース色 |

| (NO.Xm㎡) | ||||

| 1 | ¥1008.03.0050 | 3G0.5 | 7.0 | オレンジ、ブラック |

| 2 | ¥1008.04.0050 | 4G0.5 | 7.5 | オレンジ、ブラック |

| 3 | ¥1008.04.0075 | 4G0.75 | 8.2 | オレンジ、ブラック |

| 4 | ¥1008.04.0100 | 4G1.0 | 9.0 | オレンジ、ブラック |

| 5 | ¥1008.04.0150 | 4G1.5 | 10.0 | オレンジ、ブラック |

| 6 | ¥1008.04.0250 | 4G2.5 | 12.2 | オレンジ、ブラック |