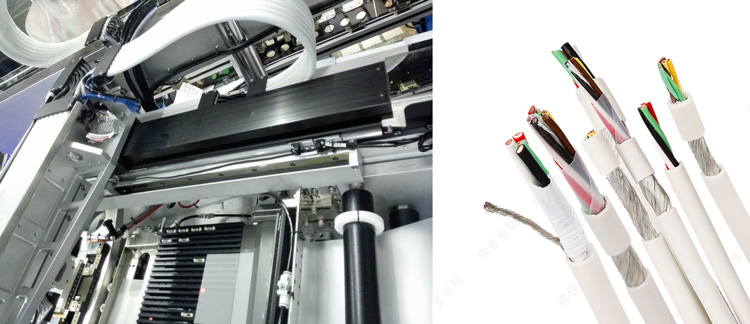

当社のケーブルアプリケーション

何か助けが必要ですか?

ここで適切なモデルが見つかりませんか?シートベンチレーションやダッシュボード、ヘッドライトなどは一部の人気モデルだけあります。ニーズに合った適切な DC ファンを入手するには、お問い合わせください。

お問い合わせChengjia Drag chain cable: an excellent choice for the medical equipment industry

The medical equipment industry is an indispensable part of today’s society, and its rapid development requires various key components to have high reliability, high performance, and compliance with strict standards and regulations. In this industry, cables are one of the core elements that connect, transmit, and support the normal operation of equipment. To meet the needs of the medical equipment industry, chengjia drag chain cables have been committed to providing excellent solutions.

- Quality is paramount, requirements of the medical equipment industry

In the medical equipment industry, there can be no compromise on the quality and reliability of products. Shundian drag chain cables are renowned for their excellent quality control standards, strictly following the ISO 9001 quality management system, and have also obtained multiple international certifications such as CE certification, UL certification, and more. This ensures that Shundian drag chain cables can meet the stringent quality requirements of the medical equipment industry, providing a safe and reliable treatment environment for patients.

- Excellent engineering design, attention to detail

In medical equipment, cables often need to bend, twist, and move in confined spaces. This demands cables to possess high flexibility and durability. Shundian drag chain cables utilize advanced engineering design to ensure the stability of the cable’s twisted structure in complex motion environments. This is particularly important for medical equipment that requires highly precise operations in operating rooms.

- Environmental protection and sustainable development

Medical equipment manufacturers are increasingly focused on the environmental performance of their products. Shundian drag chain cables are committed to environmental protection, with cables complying with environmental standards such as RoHS and REACH, while also emphasizing energy conservation and emission reduction during the production process. This not only helps protect the environment but also provides sustainable solutions for medical equipment manufacturers, enhancing the sustainable competitiveness of enterprises.

- Case analysis in the medical equipment industry

Medical imaging equipment, such as MRI and CT scanners, require large amounts of data transmission and high-quality image display. The application of drag chain cables in these devices provides reliable electrical signal transmission for high-resolution imaging, ensuring accurate disease diagnosis by doctors and timely medical services for patients.

- Future prospects

We will continue to dedicate ourselves to the medical equipment industry, continuously providing excellent cable solutions. In the future, we will uphold the enterprise spirit of “quality, innovation, and service,” constantly pioneering innovation, and providing higher performance, more reliable, and more environmentally friendly cable products and services for medical equipment manufacturers, contributing to the health of patients and the sustainable development of the healthcare industry.

Dust -free trailer cable, suitable for high -level cleansing rooms

Advantages

- The cable has a small outer diameter, saving installation space.

- It uses special TPE insulation.

- Even in applications with moving drag chains, it rarely generates particles due to wear and tear.

- It is used to shield against electromagnetic interference.

アプリケーション

- Used for power drag chains or mechanical moving parts.

- Used in measurement, control, and regulation circuits.

- Assembly lines, production lines, and almost all equipment.

- Used in humid indoor environments.

- Can only be used outdoors to prevent ultraviolet radiation within specified temperature ranges.

Product Features

- Wear-resistant and scratch-resistant.

- Flame retardant.

- Maintains flexibility at low temperatures.

- Low-friction surface.

Technical Certifications

- Clean room certification IPAISO14644-1Class1.

- CE certification.

Product Structure

- Ultra-fine bare steel wire twisted conductor (6 classes).

- Core wire insulation: TPE.

- Core wires twisted together with optimized short pitches.

- Teflon wrapping.

- Tin-plated copper braided shield, shielding rate >95%.

- Teflon wrapping. Product Features

- Wear-resistant and scratch-resistant.

- Flame retardant.

- Maintains flexibility at low temperatures.

- Low-friction surface.

- Modified PVC sheath: white (similar to RAL9003).