Technical Parameter Of Robot Towline PVC Drag Chain Cable

|

Standard

|

Rispettare le normative RoHS e Reach dell'UE

|

|||

|

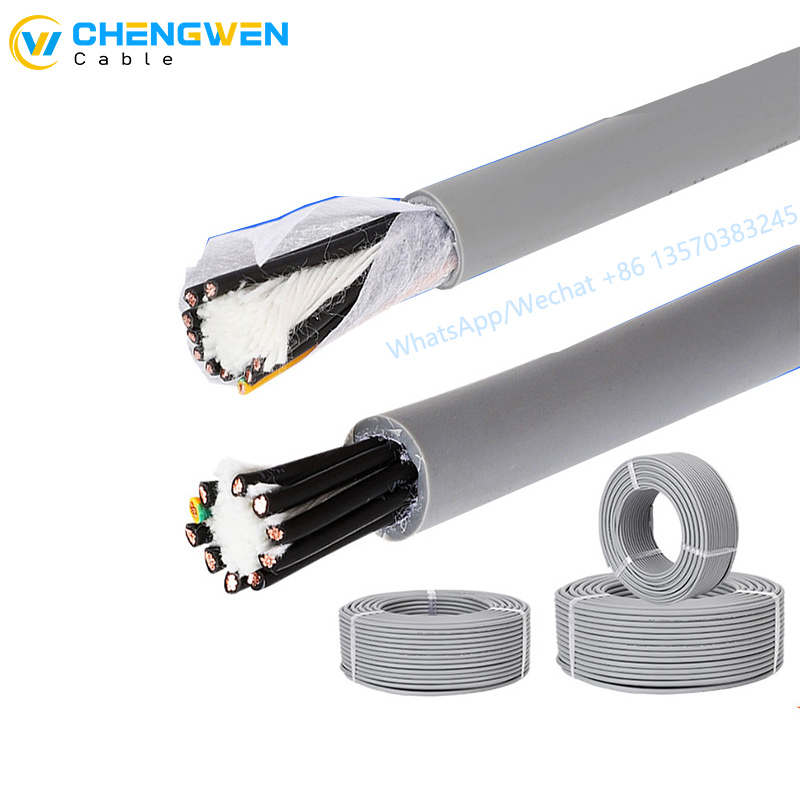

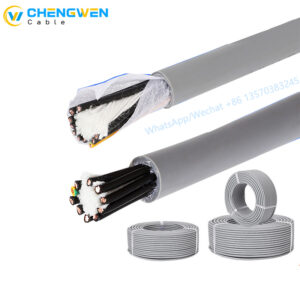

Conduttore

|

adotta filo di rame intrecciato in rame stagnato di alta qualità

|

|||

|

Materiale isolante

|

Guaina speciale in PVC ad elevata flessibilità

|

|||

|

Intervallo di temperatura:

|

Installazione mobile da -5°C a +70°C

Installazione fissa da -15°C a +80°C

|

|||

|

Resistenza di isolamento:

|

Minimo 20 MOhm x km

|

|||

|

Colore

|

Nero (altri colori possono essere personalizzati)

|

|||

|

Raggio minimo di curvatura:

|

Installazione mobile diametro cavo 7,5×

Installazione fissa 6x diametro del cavo

|

|||

|

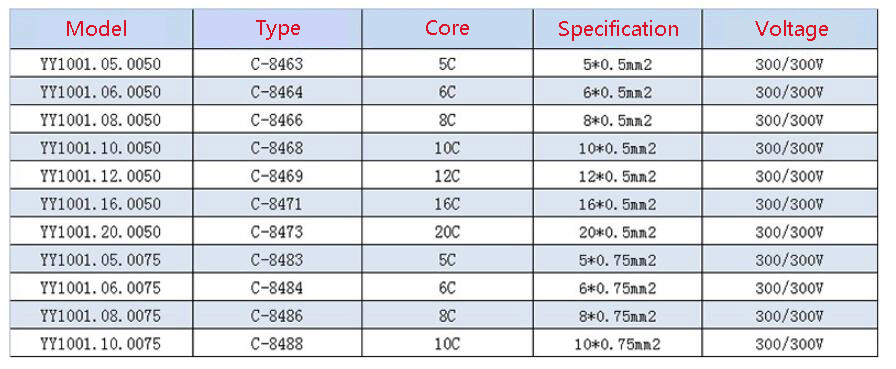

Voltaggio nominale

|

Uo/U 300/300 V

|

|||

|

Provare la tensione

|

1500 V

|

|||

|

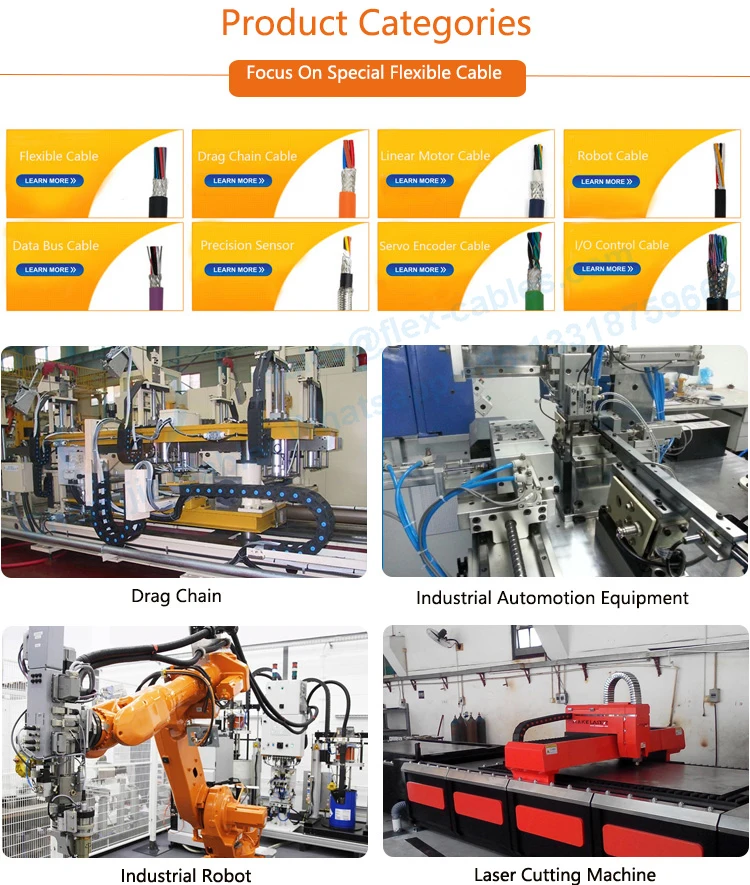

Applicazione:

|

Adatto a varie apparecchiature di produzione automatizzata non standard come macchine utensili CNC, robot industriali, servoazionamenti,

macchine per la lavorazione del legno, macchine per maschere, manipolatori, macchine dispensatrici, apparecchiature laser, linee di stampaggio, automazione logistica, apparecchiature per la produzione di ceramica, ecc., in grado di resistere ad accelerazioni a lungo termine, decelerazioni, sollecitazioni di trazione e compressione e flessione periodica ad alta velocità e mantenere sempre un'elevata stabilità. |

|||

Robot Towline PVC Drag Chain Cable Structure

Robot Towline PVC Drag Chain Cable Structure

|

NO.

|

Codice prodotto

|

Nuclei Numero e area della sezione trasversale

(NO.Xm㎡)

|

Diametro esterno approssimativo (mm)

|

Colore guaina esterna

|

Resistenza CC del conduttore 20 ℃

Oh/km

|

|

1

|

YY1001.02.0020

|

2×0,2

|

4.4

|

Grigio

|

95

|

|

2

|

YY1001.03.0020

|

3×0,2

|

4.6

|

Grigio

|

95

|

|

3

|

YY1001.04.0020

|

4×0,2

|

5.0

|

Grigio

|

95

|

|

4

|

YY1001.05.0020

|

5×0,2

|

5.2

|

Grigio

|

95

|

|

5

|

YY1001.06.0020

|

6×0,2

|

5.6

|

Grigio

|

95

|

|

6

|

YY1001.08.0020

|

8×0,2

|

6.4

|

Grigio

|

95

|

|

7

|

YY1001.10.0020

|

10×0,2

|

7.2

|

Grigio

|

95

|

|

8

|

YY1001.12.0020

|

12×0,2

|

7.0

|

Grigio

|

95

|

|

9

|

YY1001.16.0020

|

16×0,2

|

7.5

|

Grigio

|

95

|

|

10

|

YY1001.20.0020

|

20×0,2

|

8.2

|

Grigio

|

95

|

|

11

|

YY1001.02.0030

|

2×0,3

|

4.6

|

Grigio

|

71.2

|

|

12

|

YY1001.03.0030

|

3×0,3

|

4.8

|

Grigio

|

71.2

|

|

13

|

YY1001.04.0030

|

4×0,3

|

5.2

|

Grigio

|

71.2

|

|

14

|

YY1001.05.0030

|

5×0,3

|

5.6

|

Grigio

|

71.2

|

|

15

|

YY1001.06.0030

|

6×0,3

|

6.0

|

Grigio

|

71.2

|

|

16

|

YY1001.08.0030

|

8×0,3

|

6.8

|

Grigio

|

71.2

|

|

17

|

YY1001.10.0030

|

10×0,3

|

7.6

|

Grigio

|

71.2

|

|

18

|

YY1001.12.0030

|

12×0,3

|

7.4

|

Grigio

|

71.2

|

|

19

|

YY1001.16.0030

|

16×0,3

|

8.0

|

Grigio

|

71.2

|

|

20

|

YY1001.20.0030

|

20×0,3

|

8.6

|

Grigio

|

71.2

|

|

MOQ 1 metro, se è necessario ordinare la guaina esterna in PUR, MOQ 400 metri

|

|||||