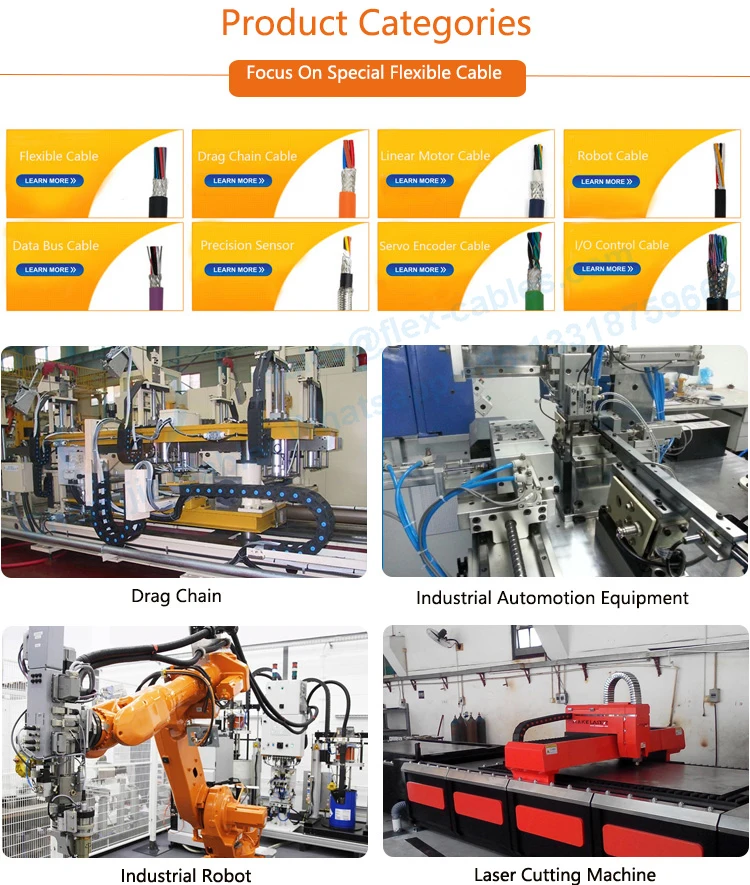

TRVVP high flexibility servo cable is suitable for installation under continuous reciprocating motion, especially the frequent

bending occasions under the industrial environment, the drag chain of modern machinery standard components and the

logistics system, operating system, mechanical automation system and other CNC machine tools, electronic equipment,

metal stamping, wood and stone Machinery, glass and door and window machinery, injection molding machines, manipulators,

robots, construction machinery, heavy machinery factories, automobile manufacturing, lifting and transportation equipment,

automated warehouses, docks, fire trucks and other indoor and outdoor environments

TRVVP High Flexibility Servo Cable Technical Parameter

|

معيار

|

الامتثال للوائح الاتحاد الأوروبي RoHS وReach

|

|||

|

موصل

|

تعتمد سلكًا نحاسيًا مجدولًا من النحاس عالي الجودة

|

|||

|

مادة العزل

|

غمد PVC خاص بمرونة عالية

|

|||

|

نطاق درجة حرارة:

|

تركيب الجوال -5 درجة مئوية إلى +70 درجة مئوية تثبيت ثابت -15 درجة مئوية إلى +80 درجة مئوية

|

|||

|

مقاومة العزل:

|

الحد الأدنى 20 ميجا أوم × كم

|

|||

|

لون

|

أسود (يمكن تخصيص ألوان أخرى)

|

|||

|

الحد الأدنى لنصف قطر الانحناء:

|

تركيب موبايل 7.5×قطر الكابل تركيب ثابت: قطر الكابل 6x

|

|||

|

الجهد الاسمي

|

يو / يو 300/300 فولت

|

|||

|

اختبار الجهد

|

1500 فولت

|

|||

|

طلب:

|

مناسبة لمختلف معدات الإنتاج الآلي غير القياسية مثل أدوات آلة CNC، والروبوتات الصناعية، ومحركات المؤازرة،

آلات النجارة، آلات القناع، المناورات، آلات التوزيع، معدات الليزر، خطوط الختم، الأتمتة اللوجستية، معدات إنتاج السيراميك، وما إلى ذلك، والتي يمكنها تحمل التسارع والتباطؤ والشد والضغط على المدى الطويل، و الانحناء الدوري عالي السرعة، ويحافظ دائمًا على الثبات العالي. |

|||

TRVVP High Flexibility Servo Cable Structure

1. Tinned copper (less than 0.5m㎡) or bare copper (0.5m㎡ and above) conductor thin copper wire, in line with DIN VDE 0295 category 6 and IEC60228 Class 6

2. عزل PVC الخاص الخاص

3. Color core wire identification (less than 0.5m㎡)

4. Black core wire, with continuous white digital code (0.5m㎡ and above), yellow-green ground wire on the outer layer (3 core and above)

5. يتم تجديل قلب السلك في طبقات ذات أفضل درجة

6. تحسين درع مضفر الأسلاك النحاسية المعلبة

7. The minimum coverage rate is 80%

8. غلاف خارجي PVC خاص

9. أسود (RAL 9005) غير لامع